Manufacturer's Industrial Resistance Furnace Activated Carbon Electric Rotary Kiln with External Heating

US $160,000.00-200,000.00 / set

1 set(s)Minimum order

place of origin:

Shanghai, China

type:

Arc Furnace

usage:

Heat Treatment Furnace

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Engine, Bearing, Gearbox, motor, Gear, Pressure vessel, Pump

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Shanghai, China |

|---|---|

| type | Arc Furnace |

| usage | Heat Treatment Furnace |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Gear, Pressure vessel, Pump |

| brand name | YINGYONG |

| voltage | 220/380/440v |

| dimension(l*w*h) | 1.6*1.6*32- 6.2*6.2*96 |

| weight (t) | 1 T |

| warranty | 1 Year |

| key selling points | Energy saving, High-accuracy, Long Service Life |

| Product name | External Heating Kiln |

| Condition | New |

| Brand Name | YINGYONG |

| Power | 800-20000KW |

| Name | Equipment Rotary Kiln Turn Key Processing Plant |

| Type | Rotary type |

| Color | Requestt |

| price | Negotiable |

| Spare parts | Supply all using life |

| Capacity | Custom |

| Warranty of core components | 1 Year |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

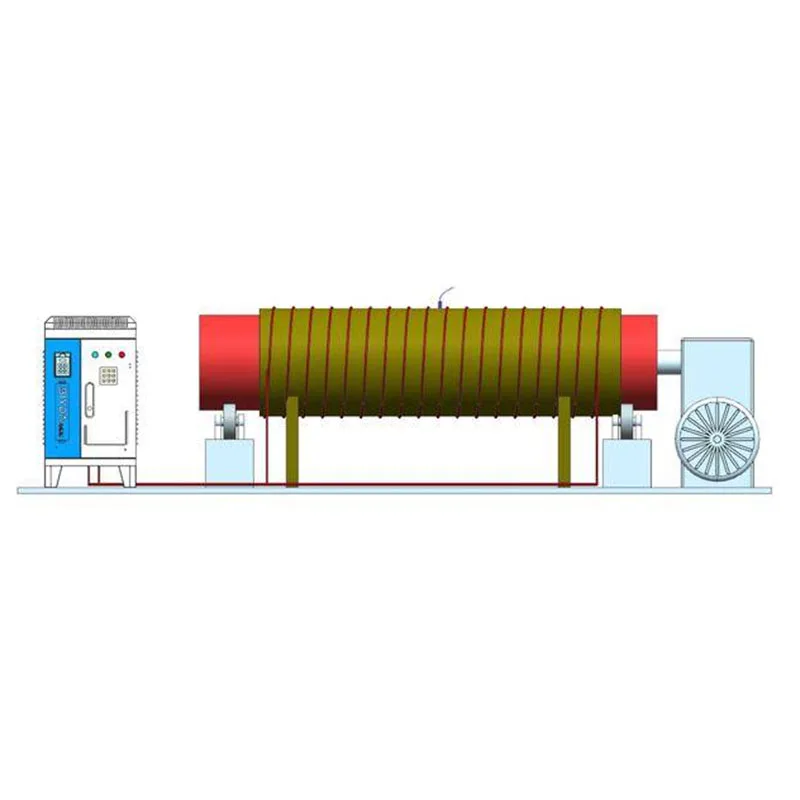

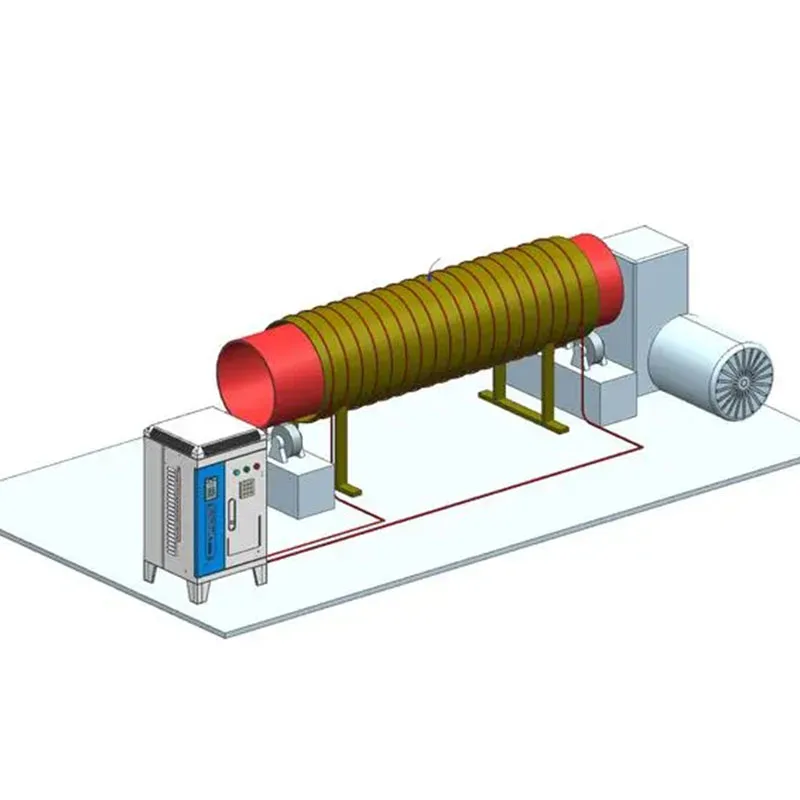

Electromagnetic rotary kiln

New ore calcination technology

Electromagnetic rotary kiln, successfully put into use. Electromagnetic heating technology, high temperature of 1200, burning ore and producing lime. Our electromagnetic heater, with heating temperature up to 1200 degrees, is perfectly suitable for high temperature heating, high temperature drying, sufficient heat, uniform heating and lower cost in industrial fields such as lime kiln, rotary kiln, reactor, stainless steel pipeline and rotating drum.

Product Advantages

Application of electromagnetic induction heating instead of the traditional transfer heating method, because the metal body is directly active heating, so there are many advantages in the application of electromagnetic heater equipment supporting, summarized as follows:

1、Direct active heating, and power density makes heating faster.

2、Metal body active heating, to avoid the loss of heat transfer and thus the use of more energy efficient.

3、No open flame and heating medium makes the operation safer and the environment cleaner.

4、All digital control system ensures more accurate temperature control and more intelligent equipment.

5、Good independence of equipment, the volume may be smaller, simple maintenance.

Using induction heating method compared to the traditional electric sun wire or gas heating, heating time can usually be shortened by more than 50%; energy-saving effect can reach at least 30%. At the same time, this heating process without any waste waste solid emissions, solving the problem of environmental protection and security inspection.

Product Parameters

NO. | Model | Temperature | Inner tube size | Power | Angle | Production capacity | Power supply | weight |

1 | YDH100 | 1100℃ | φ0.1×4.5m | 36kW | 0.5~5.0° | 4kg/h | 380VAC 50HZ | 4T |

2 | YDH150 | Φ0.15×4.5m | 42kW | 8kg/h | 4T | |||

3 | YDH200 | φ0.2×4.5m | 48kW | 15kg/h | 4T | |||

4 | YDH350 | φ0.35×9m | 68kW | 120kg/h | 8T | |||

5 | YDH400 | φ0.4×9m | 108kW | 150kg/h | 10T | |||

6 | YDH500 | φ0.5×9m | 180kW | 250kg/h | 12T | |||

7 | YDH620 | φ0.62×10.5m | 260kW | 300kg/h | 15T | |||

8 | YDH700 | φ0.7×10.5m | 280kW | 360kg/h | 18T | |||

9 | YDH800 | φ0.8×10.5m | 350kW | 480kg/h | 20T | |||

10 | YDH940 | φ0.94×12m | 400kW | 650kg/h | 25T | |||

11 | YDH1000 | φ1.0×12m | 410kW | 750kg/h | 28T | |||

12 | YDH1100 | φ1.1×12m | 460kW | 900kg/h | 30T | |||

13 | YDH1250 | φ1.25×12m | 500kW | 1000kg/h | 35T | |||

14 | YDH1420 | φ1.42×13.5m | 600kW | 1350kg/h | 40T | |||

15 | YDH1500 | φ1.5×13.5m | 750kW | 1500kg/h | 45T | |||

16 | YDH1600 | φ1.6×15m | 900kW | 1600kg/h | 50T | |||

17 | YDH1800 | φ1.8×15m | 1000kW | 1900kg/h | 55T | |||

18 | YDH2000 | φ2.0×15m | 1100kW | 2200kg/h | 60T | |||

19 | YDH2200 | Φ2.2×15m | 1300kW | 2600kg/h | 70T |

Working Principle

The external thermoelectric rotary kiln is mainly composed of six parts, such as combustion system, control system, heating cavity simplified, kiln body, driving device, feeding and discharging system. All the components are installed on the overall frame made of steel structure.

1、The combustion system is mainly composed of burner, proportional control valve, solenoid valve, electric actuator, atomization and combustion device, ignition The combustion system mainly consists of burner, proportional control valve, solenoid valve, electric actuator, atomization combustion device, ignition device, etc.

2、Simplified body with sprocket or gear, supported by rollers at both ends, driven by FM motor through sprocket or gear. Cylinder body Material can be chosen according to the process requirements. It is equipped with copying plate inside.

3、The kiln body is located on a steel frame, mainly made of light insulation materials. Folding block is used, and zirconium-containing ceramic wool blanket is used to reduce heat storage. The labyrinth seal is formed by the refractory material and the flame-retarding ring of the simplified part.

4、Driving device can be used chain drive and gear drive, the reducer has two out shafts, can add a manual device, so that the emergency shaking the simplified to protect it from being damaged.

5、Feeding and discharging system, mainly composed of feeding hopper, feeding screw, stirring device, feeding cover, etc.

6、Electrical heating device, according to the thermocouple display temperature and the finished product of baking a thousand situations, adjust the power of the electric heating device, so as to change the drying effect.

The material to be burned is evenly fed into the barrel of the kiln from the hopper at the head of the kiln through the feeding mechanism, and driven by the transmission device, the material advances axially along the barrel with the rotation of the barrel, and the plate turns over the material to make it calcine evenly. The outer side of the cylinder is equipped with a heating chamber. The heat generated by calcination is transmitted to the material through the cylinder, and the material is decomposed, dried, calcined and roasted under high temperature. The calcined materials are discharged through the discharge valve and used after being cooled and packed.

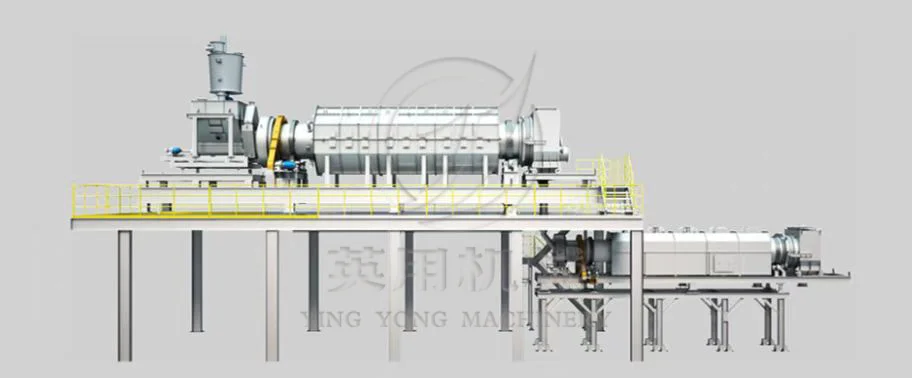

Case Show

Electromagnetic rotary kiln, industrial high temperature heating 1200 degrees, calcination of ore, mass production of lime.

Flame isolation rotary kiln External heat rotary kiln Dynamic calcination rotary kiln Electric heating high temperature rotary kiln.

Used for the roasting of new battery materials, using electric heating, two-stage tandem combination roasting.

Electromagnetic heating technology, high temperature of 1200, burning ore and producing lime.

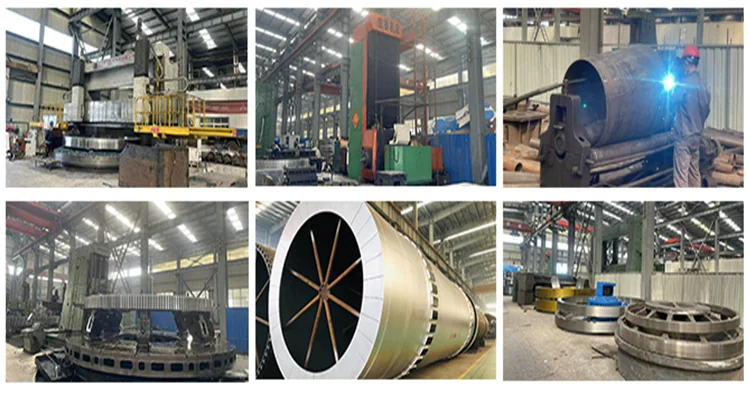

About Us

Shanghai Yingyong Machinery Co., Ltd. is a professional rotary kiln manufacturer, specializing in the production of high-temperature equipment solutions for many years. We specialize in producing various cement machinery, metallurgical machinery, power equipment, and mining machinery. We have the strength in design, research and development, manufacturing, installation and debugging, as well as after-sales service.

Our main products include: ball mills, vertical roller mills, rotary kilns, crushers, roller presses, plate feeders, coolers, stackers and reclaimers, powder concentrators, and NPK compound fertilizer equipment.

We have completed many EPC factory projects for domestic and foreign clients and have won high praise from them. Our products have been exported to over 100 countries, including the United States, Russia, Spain, Italy, Saudi Arabia, Finland, Australia, Indonesia, Brazil, Chile, Pakistan, Egypt, Mexico, Kazakhstan, etc.

Product Certification

1.Our products have passed CE and ISO, and we can provide you with OEM products and accept inspections from internationally renowned testing companies such as SGS, TUV, BV, etc.

2. We can provide you with high-quality products and one-stop solutions.

3. We provide 24-hour online consultation. Welcome to inquire and visit our factory. We look forward to working with you!

Q&A

1.How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

2. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

The quality of our mining equipment is something we take immense pride in. All our products are manufactured in compliance with the highest industry standards, including [mention any relevant certifications, e.g., ISO 9001]. We use only the best materials and cutting-edge technology to ensure that our machines are not only durable but also highly efficient and reliable.

4.How about price?

For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

5.Service and Payment Terms?

We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.