Mining Industrial Mineral Limestone Gypsum Coal Powder Grinding Mill Factory Price

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Gearbox, motor, Gear |

| Type | ultra fine powder mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 0.5-45 |

| Place of Origin | Shanghai |

| Brand Name | Clirik |

| Dimension(L*W*H) | 5 models |

| Weight | 1500 KG |

| Warranty | 1 Year |

| Control System | PLC |

| Motor Brand | Siemens |

| Color | Customizable |

| Feeding Size | 0-20mm |

| Output Size | 150-3000 mesh |

| Market | Global |

| Factory Visit | Welcomed Warmly |

| Usage | Moh's hardness no more than 7 minerals |

| Grinding Parts Uages | 6-12 months |

| Online Service Time | 24 Hours Online |

| Applicable Industries | Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

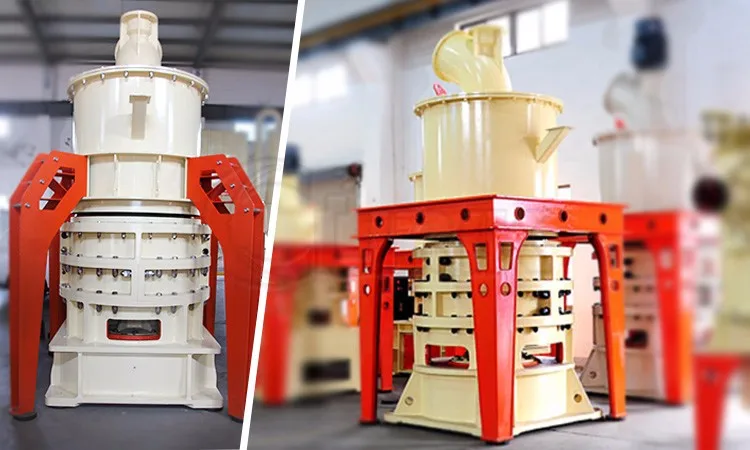

Mining Industrial Mineral Limestone Gypsum Coal Powder Grinding Mill Factory Price

*every production line needed machines is difference*

*the final quotation will according to your project case*

Name: 500 Mesh Superfine Quarry Caco3 Talc Barite Limestone Coke Slag Crushing Machine

Model: HGM series

Brand: Clirik

Powder Fineness Process Ability: 150-3000 mesh

Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0.5-45 t/h

Use Range: can be used in more than 300 kinds of stone materials powder grinding, such as: calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble and so on

Application: mining, chemiscal, transport and many other different areas

Parameter of HGM ultra fine grinding mill

| Model |

Ring Diameter (mm) |

Ring Number (PCS) |

Roller Number (PCS) |

Shaft Speed (r. p. m) |

Input Size (mm) | Finished Size (mesh) | Capacity (t/h) |

Outlet Size L*W*H (m) |

Power Consumption (KW) |

| HGM80 | 800 | 3 | 21 | 230-240 | ≤10 | 150-3000 | 0.5-5.5 | 8605*4139x6050 | 142 |

| HGM80A | 800 | 3 | / | / | ≤10 | 150-3000 | 0.5-5.5 | 10454*3393*6626 |

142 |

| HGM90L | 900 | 4 | 24-32 | 200-220 | ≤10 | 150-3000 | 0.8-6.5 | 11735*3952*7525 | 180 |

| HGM100L-Ⅱ | 1000 | 4 | 27 | 180-200 | ≤15 | 150-3000 | 1.2-10 | 14507*3633*7562 | 242 |

| HGM100P | 1000 | 4 | 34 | 180-200 | ≤15 | 150-3000 | 1.2-11 | 14362*4200*7562 | 267 |

| HGM125L | 1250 | 4 | 40-44 | 135-155 | ≤20 | 150-2500 | 2.5-20 | 19261*4406*8591 | 401 |

| HGM1680L | 1680 | 4 | 30-40 | 120-130 | ≤20 | 150-2000 | 5-45 | 25067*5414*9007 | 665-685 |

Application of HGM ultra fine grinding mill

HGM Ultra Fine Grinder mill is mainly applied to non-inflammable, non-explosive and brittle materials with Mohs hardness under six. Such as calcite (calcite carbonate, calcium carbonate), chalk, limestone, dolomite, kaolin, gypsum, etc, totally more than 300 kinds of materials. Product fineness can be controlled between 0.047 and 0.005mm. And the HGM ultra fine grinding mill is a device that breaks solid materials into powder by grinding, Such comminution is an important unit operation in many processes. It is usually used in Metallurgy, building materials, chemical and mine industries.

Wear Parts of HGM ultra fine grinding mill

HGM ultra fine grinding mill wear parts including: Discharging Valve, Siemens Cabinet, Clasifer Impeller, Filter Bag, Pins, Turn Plates, Grinding Rings and Grinding Rollers, Shanghai Clirik Machinery as a professional grinding mill manufacturer also can supply these wear parts for you.

Working Principle&Flow of HGM ultra fine grinding mill

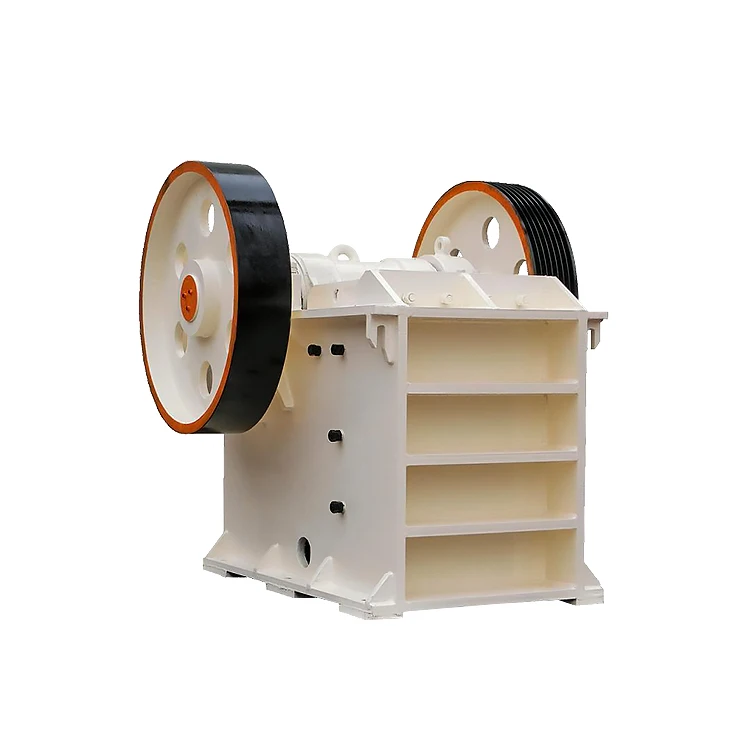

1. Large pieces of material are crushed to the required size by the jaw crusher.

2. Crushed material is sent to the storage hopper by elevator.

3. Vibrating feeder send material to the main grinding chamber evenly and continuously for grinding.

4. The ground powder is taken away by the airflow of the fan and classified by the analyzer.

5. The finished product that meets the fineness is collected by the airflow through the pipe, then into the large selection air collecting pipe.

6. The material is discharged through the powder outlet pipe to become the finished powder.

Advantages of HGM ultra fine grinding mill

1. HGM Ultrafine Grinding Mill has successfully replaced the jet mill, ball mill etc, simplifty the flow, reduce the production cost and increase the final powder fineness.

2. Wearing parts are made of wear-resistant materials. High utilization rate of Wear material: 2-5years.

3. Integrated design of powder milling and powder selection, with a smaller footprint.

4. Multi-layer grinding ring design for higher grinding efficiency

5. Wide grinding range. Adjustable particle size: 200-3000 mesh.

6. The structure is firm and reliable. The design of the mill is rigorous, so no screw loosening to damage the machine.

7. The operation of intelligent control system is more convenient.

8. Grinding cavity fully enclosed design and sound insulation room design. It is the green and ideal equipment for environment protection.

Certification of HGM ultra fine grinding mill

As a professional grinding mill manufacturer in China, Shanghai Clirik had passed CE, ISO9001:2008, BV, SGS...and other many certification, and we also have our own patents.

------------------------------------------------------------------------------------------------------------------------------------------------------------

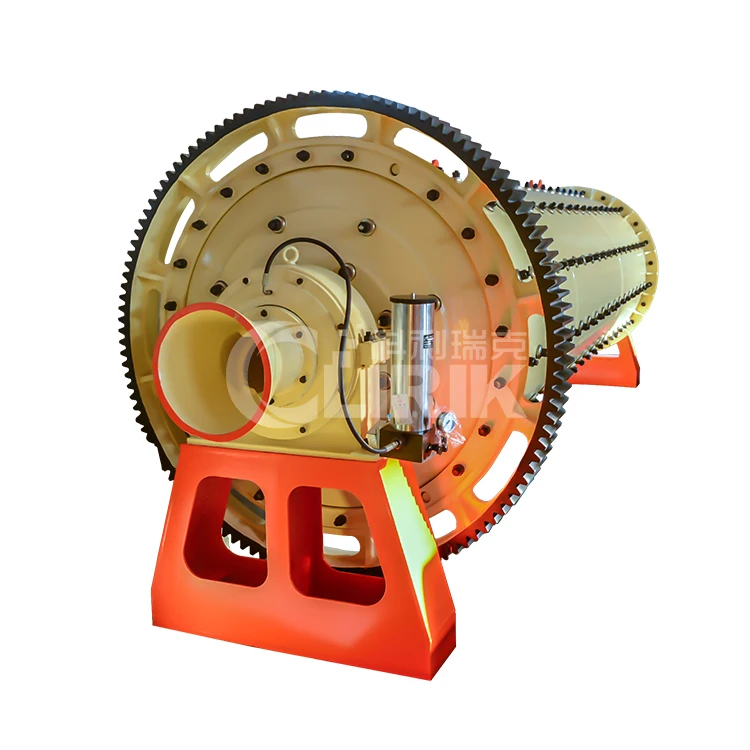

Related Products

If you need other mining use machines, you are welcome to visit our

there are several other mining use machines we can supply as following...

|

|

|

|

|

for large industry, the final powder fineness is more unifrom |

hammer crusher, jaw crusher, cone crusher, impact crushers... |

------------------------------------------------------------------------------------------------------------------------------------------------------------

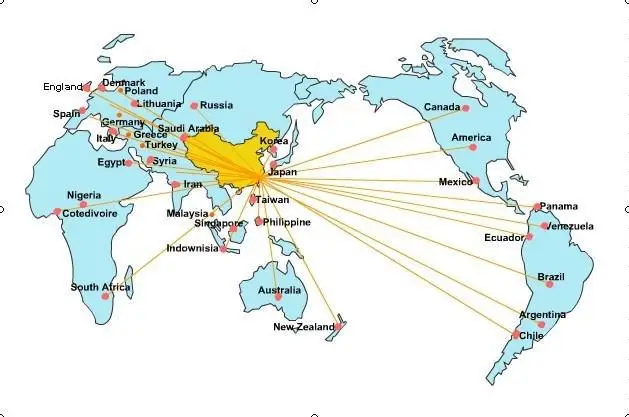

Shanghai Clirik Machinery Co. Ltd., keep the service idea of "creat more value to customers" , treating our customers with all our hearts, and meantime lawfully running it.

Our customers distribute in over 120 countries in Asia, Europe, Middle east,Oceania and America. We apply our professional knowledge and full global service capability to ensure the best results for our customer's business.

Pre-sale services

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments;

♥ Select equipment model;

♥ Sdeign and manufacture products according to clients' special requirement;

♥ Train technical personnel for clients.

Services during the sale

Respect clients; devote ourselves to improving the total value of clients.

♥ Pre-check and accept products ahead of delivery;

♥ help clients to draft solution.

After-sales service

Provide considerate services to minimize clients' worries.

♥ Assist clients to prepare for the first construction scheme;

♥ Install and debug the equipment;

♥ Train the first-line operators on site;

♥ Examine the equipment regularly;

♥ Take initiative to eliminate the troubles rapidly at site;

♥ Distribute the guarantee fittings door-to-door;

♥ Provide technical exchanging;

♥ Provide maintenance for big items.

Clirik also can supply the door-to-door service for every customers, just set your order on Alibaba, we will transport the grinding mill to you.

1. who are we?

Shanghai Clirik Machinery Co.Ltd., based in Shanghai, China, start from 2010,sell to Mid East(30.00%),Africa(20.00%),Southeast Asia(19.00%),South Asia(15.00%),North America(3.00%),South America(3.00%),Domestic Market(3.00%),Southern Europe(2.00%),Eastern Europe(00.00%),Eastern Asia(00.00%),Western Europe(00.00%),Central America(00.00%),Northern Europe(00.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Grinding Mill(other needed mining equipment used in stone powder production line project)

4. why should you buy from Clirik not from other suppliers?

1. CE, ISO9001

2. factory sell directly

3. 30 years experience, professional

4. Sales market all over the world

5. good after sales serive

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,French

Shanghai Clirik Machinery