New 3-in-1, One Machine for Laser Cutting, Welding and Cleaning 1000W-3000W

US $2,800.00-3,000.00 / set

1 set(s)Minimum order

condition:

New

Output Power:

3000w

usage:

metal welding cleaning cutting

place of origin:

China

brand name:

/

single pulse energy:

220V 50/60HZ

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| condition | New |

|---|---|

| Output Power | 3000w |

| usage | metal welding cleaning cutting |

| place of origin | China |

| brand name | / |

| single pulse energy | 220V 50/60HZ |

| pulse width | / |

| wavelength | 1064nm |

| focal spot diameter | / |

| dimensions | 1300*720*1200mm |

| warranty | 2 years |

| laser source brand | RAYCUS /IPG / Max |

| laser head brand | WSX / Ospri |

| servo motor brand | Yaskawa /Fuji |

| guiderail brand | option |

| control system brand | / |

| weight (kg) | 300 KG |

| key selling points | Easy to Operate |

| Function | clean weld cut |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Marketing Type | Hot Product 2023 |

| Core Components | motor, laser |

Product Detail

Product Description

Product discription

Cleaning, cutting, welding three-in-one machine, the small machine has three functions, the operation is easy to understand, come and contact me!

Cleaning, cutting, welding three-in-one machine, the small machine has three functions, the operation is easy to understand, come and contact me!

Machine Model | Cleaning, cutting, welding three-in-one machine |

Laser power | 1000W 1500W 2000W 3000W(optional) |

laser wave length | 1064 NM |

Fiber length | Standard10M / Maximum 15M |

Welding speed range | 0~120 mm/s |

Cooling chiller | Industrial water chiller |

Working environment temperature range | 15~35 ℃ |

Welding thickness recommendations | 0.5-3mm |

working voltage | 220 V |

Details Images

Autofocus Laser Cutting Head

360 Degree Welding

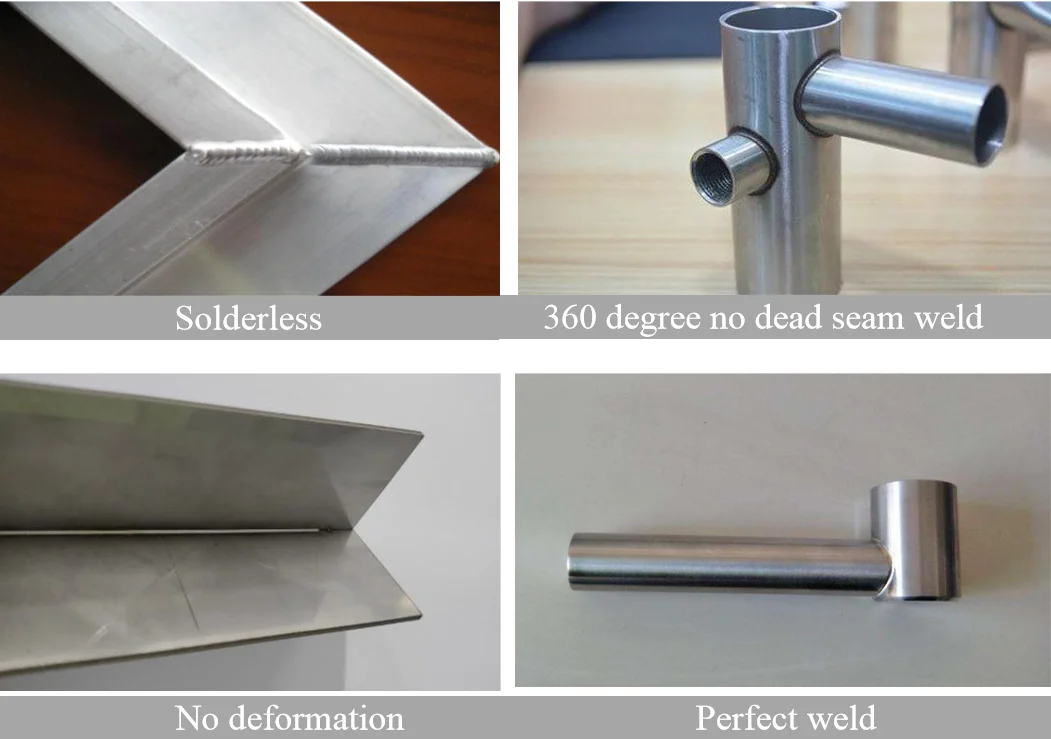

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used in the group welding of micro and small size workpieces for mass production. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stack welding, sealing welding, etc., high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, no need to be processed after welding or simply processed.

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used in the group welding of micro and small size workpieces for mass production. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stack welding, sealing welding, etc., high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, no need to be processed after welding or simply processed.

Worble Laser Head

Hand-held swing welding mode, light and flexible.Interactive control system; ;makes the light spot larger, the welding seam better formed.Lighter weight, ;ergonomic design can be equipped with a variety of angle nozzles to meet the welding needs of different products.

Samples Show

Packaging & Shipping

Machine will be packed in wooden case. We clean the machine before package, and covered anti rust oil, then packed.

1. Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool

2. Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust. The outermost is a wooden box with a fixed template.

4. Wooden box at the bottom of a solid iron socket for easy handling.

1. Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool

2. Fumigation wooden box:Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust. The outermost is a wooden box with a fixed template.

4. Wooden box at the bottom of a solid iron socket for easy handling.

Company information

Company Information

we are the manufacturer of cnc laser machines, with more than 60,000 M2 area factory and 17 years history.

Our machines are certificated by CE and widly used in more than 140 countries. We export more than 7000 set of machines in 2020.

Our mainly products:

-Fiber laser cutting machine

-CO2 laser cutting machine

-Laser welding machine

-Laser cleaning machine

-Laser marking machine

We could also provide top quality machine and service, with 24 hours technical support, free installation guidance, and long warranty (3 years).

we are the manufacturer of cnc laser machines, with more than 60,000 M2 area factory and 17 years history.

Our machines are certificated by CE and widly used in more than 140 countries. We export more than 7000 set of machines in 2020.

Our mainly products:

-Fiber laser cutting machine

-CO2 laser cutting machine

-Laser welding machine

-Laser cleaning machine

-Laser marking machine

We could also provide top quality machine and service, with 24 hours technical support, free installation guidance, and long warranty (3 years).

Exhibition

Certificate

FAQ

1. What is fiber laser cutting machine?

Fiber laser cutting machine adopts fiber laser source to output laser beam in high power density, which is focused on the

artifacts to make the irradiated area fused and gasified. Then the laser head controlled by the CNC system moves on to cut the artifacts automatically.

artifacts to make the irradiated area fused and gasified. Then the laser head controlled by the CNC system moves on to cut the artifacts automatically.

2. What material can fiber laser machine cut?

Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, copper, brass and other metal sheet and pipe.

3. What's the max. cutting thickness?

Cutting thickness is related to laser power.

300W: 1.5mm stainless steel, 4mm carbon steel

500W: 3mm stainless steel, 6mm carbon steel

1000W: 5mm stainless steel, 12mm carbon steel

2000W: 10mm stainless steel, 18mm carbon steel

300W: 1.5mm stainless steel, 4mm carbon steel

500W: 3mm stainless steel, 6mm carbon steel

1000W: 5mm stainless steel, 12mm carbon steel

2000W: 10mm stainless steel, 18mm carbon steel

4. I never used this kind of machine before. Is it easy to install and operate this machine?

We provide machine manuals, operation procedures and other relevant materials, including video CD and English instruction manual.

If required, our technicians will follow up the installation and debugging in the whole process and provide about 3-7 days free operation and maintenance training for customers.

If required, our technicians will follow up the installation and debugging in the whole process and provide about 3-7 days free operation and maintenance training for customers.

5. How long will it take to learn to operate a laser machine?

If you are able to use some basic graphic design software, it will only take a few hours to master the operation. You just need to do some simple tests on different processing materials to know how to set the correct speed and laser power.