New Designed Stamping Production Line for Food Packing Aluminum Foil Tray

Other recommendations for your business

Contact us

Quik Detail

| cnc or not | CNC |

|---|---|

| machine type | Punching Machine |

| slide stroke (mm) | 240 |

| power source | Pneumatic |

| place of origin | Shandong, China |

| brand name | BESCO |

| voltage | 220V/380 |

| dimension(l*w*h) | as requirement |

| motor power (kw) | 5.5 |

| model number | as model |

| weight (t) | 7.5 |

| key selling points | High Productivity |

| warranty | 2 years |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

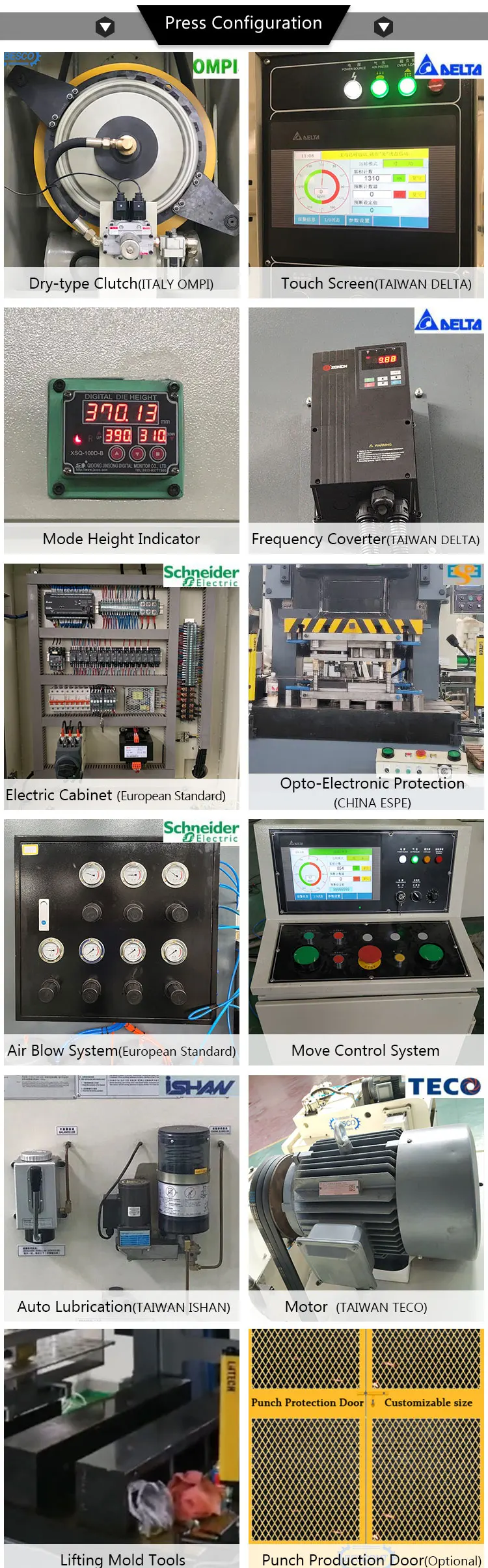

| core components | Bearing, Pump, Gear, motor, Gearbox, PLC, Pressure vessel, Engine |

| Advantage | high precision,high stability |

| mould | one cavity or multi-cavities type |

| Frequency converter | adjust punching speed |

| mould material | SKD11 |

| Lubrication style | auto lubrication |

| After-sale service | Overseas Service Provided |

| Packing | Wooden Box Packaging |

| Application | aluminum foil container for food packaging machine |

| electric control cabinet | European standard, Schneider, delta |

| machine body treatment | heat treatment |

| Condition | New |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Food & Beverage Shops |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia |

| Warranty of core components | 1 Year |

| Marketing Type | Hot Product 2024 |

Product Detail

Model | 45T | 63T | 80T |

A | 1300 | 1300 | 1300 |

B | 1200 | 1400 | 1500 |

C | 2700 | 2700 | 2700 |

D | 1000 | 1150 | 1250 |

E | 2150 | 2150 | 2150 |

F | 1300 | 1500 | 1800 |

G | 900 | 900 | 900 |

H | 1600 | 1600 | 1600 |

Model | Unit | 45T | 63T | 80T |

Norminal Pressure | KN | 450 | 630 | 800 |

Norminal Pressure Stroke | mm | 4 | 4 | 4 |

Slider Stroke | min | 220 | 240 | 280 |

Stroke times | mm | 40-70 | 40-70 | 30-70 |

Max mold height | mm | 450 | 450 | 500 |

Mold height adjustment | mm | 60 | 80 | 80 |

Worktable Size | mm | 800*900 | 1100*1100 | 1460*900 |

Worktable Plate Thickness | mm | 110 | 130 | 110 |

Top Worktable Size | mm | 340*410 | 580*400 | 750*520 |

Motor Power | KW | 5.5 | 7.5 | 11 |

Weight | Kg | 5000 | 8000 | 11500 |

Auto Stacker is a necessary part for the production of aluminum foil containers to achieve full automation. As aluminum foil containers are widely used in the field of wash free food packaging, manual collection of each product is bound to pollute the product twice, which can not ensure food safety. In addition, the aluminum foil container is very easy to deform in the process of manual collection, counting and packaging, resulting in many deformation traces on the product surface and unsightly.

Packaging: Standard foreign trade wooden box export packaging

Warranty pertod: 2 years

Technical service: available(online + offline) Operation & maintenance manual(English Version)available

Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

4.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.