New Famous Design Metal Steel Wall Panel Cladding Roll Forming Machine for Roof Panel and Wall Panel Making Machine

US $15,000.00-15,500.00 / set

1 set(s)Minimum order

Type:

Tile Forming Machine

Tile Type:

Colored Glaze Steel

Use:

Roof and wall

Production Capacity:

15-20m/min

Place of Origin:

Hebei, China

Brand Name:

ZTRFM

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Tile Forming Machine |

|---|---|

| Tile Type | Colored Glaze Steel |

| Use | Roof and wall |

| Production Capacity | 15-20m/min |

| Place of Origin | Hebei, China |

| Brand Name | ZTRFM |

| Voltage | 380V 50Hz 3phases or as your requirement |

| Dimension(L*W*H) | 9500*1700*1600mm |

| Weight | 7500 kg |

| Warranty | 1 Year, One year,and life long technical support |

| Key Selling Points | New design |

| Rolling thinckness | 0.3-0.8mm |

| Feeding width | 1220mm or as customer's request |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | motor, Gear, PLC |

| Name | Metal steel wall panel cladding roll forming machine for roof and wall |

| Usage | Roof and wall panel |

| Suitable raw material | Color steel,galvanized steel,Alu-zinc |

| Suitable raw material thickness | 0.4-0.8mm |

| Material of rollers | 45# steel with chromed treatment |

| Shaft diameter | 80mm,solid |

| Encoder brand | Siemens |

| Low pressure apparatus | Schneider |

| Certification | ISO,CE |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works |

| Showroom Location | India |

| Condition | New |

| Warranty of core components | 1 Year |

| Marketing Type | New Product 2022 |

Product Detail

Product Description

Metal steel wall panel cladding roll forming machine for roof panel and wall panel making machine

Metal steel wall panel cladding roll forming machine for roof panel and wall panel making machine is a machine to produce the new design roofing panel wall panel for Vietnam customer,we design the profiles with our customers together.

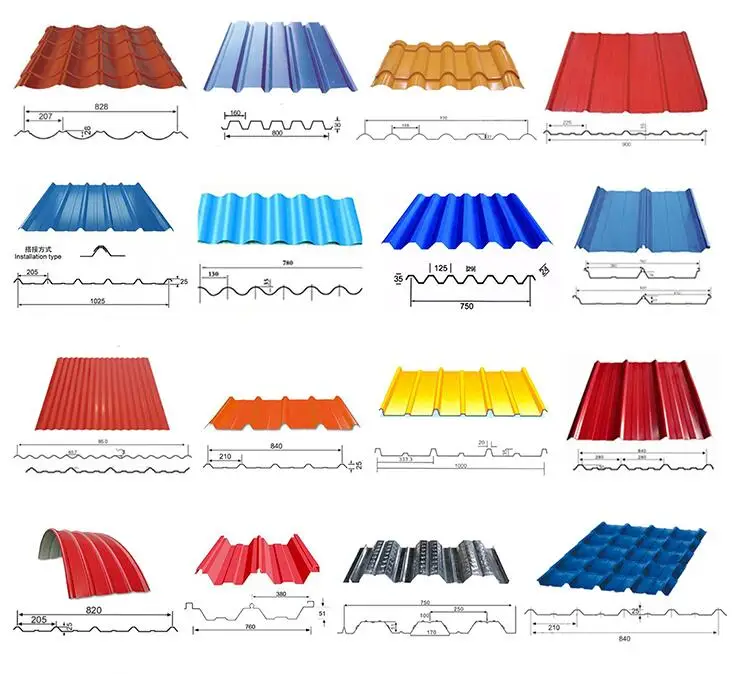

Profile drawing for the new design roofing panel and wall panel:

The Metal steel wall panel cladding roll forming machine for roof panel and wall panel making machine's pictures:

Roofing sheet installation and application:

Metal steel wall panel cladding roll forming machine for roof panel and wall panel making machine | ||||||||

1.Formed Material | PPGI,GI,AI,GL | Thickness:0.3-0.8mm Width:1250mm(As per profile drawing) | ||||||

2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||||||

3.Main body | Roller station | 26 rows(As the profile drawing) | ||||||

Diameter of shaft | 80mm solid shaft | |||||||

Material of rollers | 45# steel, hard chrome plated on the surface | |||||||

Machine body frame | 350 H steel | |||||||

Drive | Chain transmission | |||||||

Dimension(L*W*H) | 8500*1600*1600(customize) | |||||||

Weight | 7.5T | |||||||

4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||||||

5.Power | Motor Power | 5.5KW | ||||||

Hydraulic system power | 4KW | |||||||

6.Voltage | 380V 50Hz 3Phase | As your requirement | ||||||

7.Control system | Electric Box | Customized(famous brand) | ||||||

Language | English(Support multiple languages) | |||||||

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||||||

18.Forming Speed | 15-20m/min | The speed is adjustable | ||||||

More detailed pictures for the whole production line:

Hydraulic decoiler

1.Automatic working

2.Hydraulic expansion

3.With press arm to keep the coil from loosing

4.With braking system and speed sensor to match the speed with other machines

Manual decoiler

1.Working type:Unpowered

2.With hand-wheel for easy operation

3.With manual braking system

Main roll former

To roll form the finished product very precision

Rollers1.Surface with chromed treatment

2.Roller Material:45# steel

2.Roller Material:45# steel

Control system

T.Touch screen and PLC:Siemens

2.Function:To control the length,quantity and batch of the finished product

T.Touch screen and PLC:Siemens

2.Function:To control the length,quantity and batch of the finished product

Hydraulic station

1.Equipped with fan cooling systemt

Cooperated brand

Production process

Finished roll forming machine testing before delivery:

Machines are customized as your drawing,here hot sale drawing profiles for your reference.

Why Choose Us

Company Profile

Customer Photos

Customer good feedback of our machines:

Product packaging

Recommend Products