New Lab Mini Film Blowing Machine Automatic PP PE PVC PET Plastic Processing with Single Screw Extruder Manufacturing Plant

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PE, PP, PVC, PET |

|---|---|

| output (kg/h) | 2 - 6 |

| screw diameter (mm) | 25 |

| weight (kg) | 480 |

| number of layers | Single-layer |

| brand name | XH |

| place of origin | Guangdong, China |

| die size(mm) | 1 - 1.5 mm |

| model number | XH-430B |

| voltage | 380V |

| dimension(l*w*h) | 1800*800*2100mm |

| key selling points | Easy to Operate |

| warranty | One year |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, motor, Extruder, Screw, Air Ring |

| Blow Moulding Type | Extrusion Blow Moulding |

| Automatic | Yes |

| Main motor | 2.2kw |

| Air Ring size | 320mm |

| Application | Film |

| Condition | New |

| Applicable Industries | Manufacturing Plant, Laboratory |

| Showroom Location | None |

| Warranty of core components | 1 Year |

| Year | 2023 |

Product Detail

Product Application

2) New material formula development;

3) Film blowing property test;

4) Master batch color dispersion test;

5) Optimization of blown film production technology;

6) Production of simple layer tubular film blowing..

SPECIFICATIONS FOR XH-430 BLOWN FILM MACHINE | ||||||

Technical Parameters | Screw diameter | 25mm | ||||

Screw L/D | 33:1 | |||||

Screw rotating speed | 0-95 rpm | |||||

Main motor power | 2.2KW | |||||

Die diameter | 25mm | |||||

Film thickness | 0.02-0.2mm | |||||

Max fold width of film | 200mm | |||||

Power supply | 380V/50Hz/3 phases or customerized | |||||

Control system | SIEMENS PLC touching screen control | |||||

Main Features

1) Specially manufactured screw and barrel to guarantee precision and quality;

2) International brand variable speed control motor to precisely control the screw rotating speed;

3) The blown film frame can be electrically lifted, which is easy to lead the film and adjust the production technology;

4) Equipped with retractable unit for the blown film frame to easily transport and move;

5) SIEMENS touching screen PLC control system;

Machine Parts

Name: Control System

Siemens PLC control system

All operating will be done on the PLC interface, such as set temperature for each zone, adjust the screw speed, traction speed and winding speed, start/stop heating, start/stop screw rotate,winding, blowing and so on. It's very easy for operation the machine.

Main Features

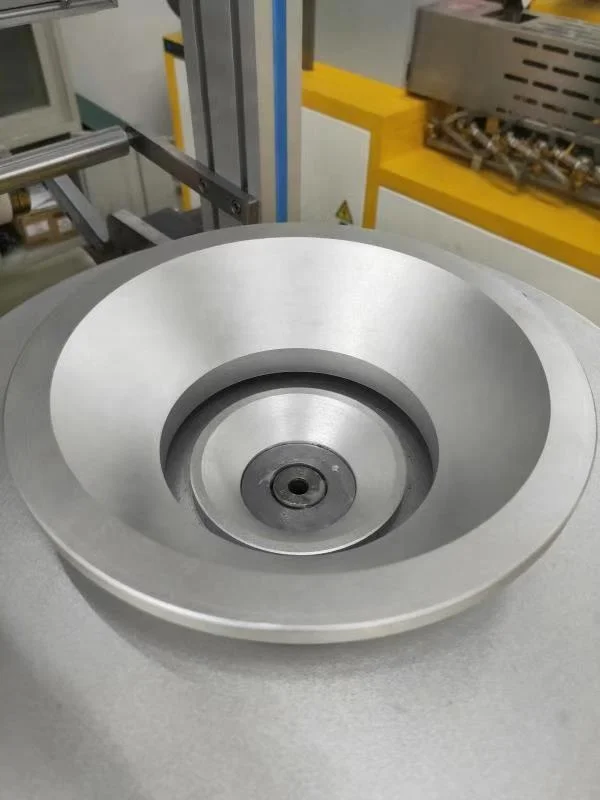

Name: Blow film die

The diameter of blow film die is 25mm.

Machine Parts

Name: Testing film samples

The max fold width for film can be adjust from 60mm to 200mm. Film thickness can be adjust 0.02-0.2mm

Main Parts

Name: Winding device

* Sample testing support.

* View our Factory.

* Engineers available to service machinery overseas.

Wechat: +86 18664021460

Website: www.lab-xh.com

Packaging | ||

Size | 1950*950*2300mm | |

Weight | about 560kgs | |

Packaging Details | wooden cage | |