New Mobile Impact Crusher Machine Steel Essential Gear Components and PLC Core for Mining & Manufacturing Ore Crushing

US $10,000.00 / set

1 set(s)Minimum order

Type:

Impact Crusher

Application:

concrete mining

Motor Type:

AC Motor

Capacity(t/h):

20-300

Place of Origin:

Henan, China (Mainland)

Brand Name:

STM

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Impact Crusher |

|---|---|

| Application | concrete mining |

| Motor Type | AC Motor |

| Capacity(t/h) | 20-300 |

| Place of Origin | Henan, China (Mainland) |

| Brand Name | STM |

| Dimension(L*W*H) | 4600x1700x2200mm |

| Weight | 15000 KG |

| Warranty | 1 Year |

| Machinery Test Report | Not Available |

| Video outgoing-inspection | Provided |

| Core Components | PLC, Gear, Engine |

| Key Selling Points | Easy to Operate |

| Product name | Impact Crusher Machine |

| Usage | Crushing Work |

| Installation | Engineer Guide |

| Spare parts supply | Lifelong Time |

| Crusher type | Hammer Heads |

| Color | Customer Requirement |

| Max feeding size | 200-1020mm |

| Price | FOB |

| Processed Materials | 200 Kinds Materials(<300 Mpa) |

| Test&Installation | Pofessional Engineer Assigned |

Product Detail

Product Overview

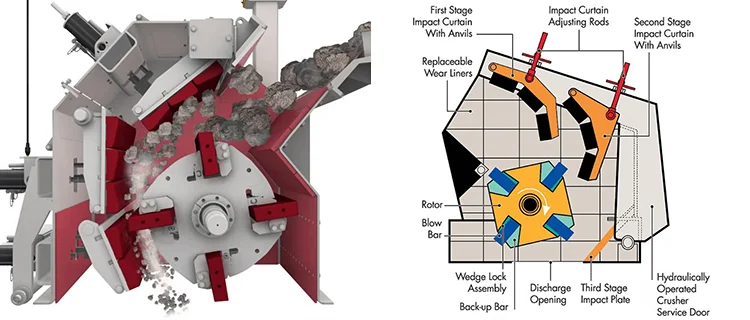

Secondary Crushing- Impact Crusher

Processed Materials:Limestone, Granite, Gabbro, Basalt, River Stone, Coal Gangue, Quartz, Diabase,Iron Ore, Copper Ore, Zinc Ore,Manganese Ore, etc. (for Soft Stone)

FEATURES AT A GLANCE

1. Optimization design of ship form frame structure, the low vehicle chassis, compact and reasonable structure, modular assembly

structure, small turning radius and convenient transporation.

2. Folding type feeding bin, hydraulic support guard board, easy and reliable operation

3. The control cabinet equips with the advanced words touch control screen, PLC control system, ensureing the function of

starting, process adjustment, misoperation tip and protection, electrical control operation, fault and safety tip.

4. The feeder can presort fines, automatic design for silo door, controlling the direction of dividing material

5. The angle of conveyor is adjustable, and the conveyor can be turned and folded, extending operation conditions, easy for

transporation.

6. Adopt stream-line design for vehicle structure, compact and reasonable mechanics optimization structure.

structure, small turning radius and convenient transporation.

2. Folding type feeding bin, hydraulic support guard board, easy and reliable operation

3. The control cabinet equips with the advanced words touch control screen, PLC control system, ensureing the function of

starting, process adjustment, misoperation tip and protection, electrical control operation, fault and safety tip.

4. The feeder can presort fines, automatic design for silo door, controlling the direction of dividing material

5. The angle of conveyor is adjustable, and the conveyor can be turned and folded, extending operation conditions, easy for

transporation.

6. Adopt stream-line design for vehicle structure, compact and reasonable mechanics optimization structure.

E

Right elevation

Left elevation

Front elevation

PRODUCT SPECIFICATIONS

Model | Specifications(mm) | Input port size(mm) | Input size(mm) | Capacity(t/h) | Power Model | Power(kw) | Weight(t) | Length*width*high (mm) |

PF-1007 | Φ1000×700 | 400×730 | 300 | 35-50 | Y250M-6 | 37 | 9.5 | 1800×1600×1800 |

PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | Y315S-6 | 75 | 14 | 2340×2007×2500 |

PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-120 | Y315L1-6 | 110 | 17 | 2582×2053×2809 |

PF-1212 | Φ1250×1200 | 400×1250 | 350 | 70-140 | Y315L2-6 | 132 | 17.5 | 2582×2203×2809 |

PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-160 | Y315L2-6 | 132 | 22 | 2582×2403×2809 |

PF-1315 | Φ1300×1500 | 680×1520 | 350 | 90-220 | Y2-355M2-6 | 200 | 26 | 2930×2761×3053 |

PF-1320 | Φ1300×2000 | 680×1570 | 350 | 110-350 | Y2-355M2-6 | 280 | 28 | 3340×2950×3000 |

PRODUCT CONFIGURATION

Rotor

Hammer Plate

Teeth Part

Successful Project

Project in Russia

Project in Russia

Project in Russia

SIMILAR PRODUCTS

FAQ

1. What is the raw material to be grinded, limestone, granite, feldspar, barite or others?

2. What is the maximum input size of the raw material in mm or inch?

3. What is the product’s size do you want in micron or mesh?

4. What is the capacity (t/h) do you want?

5. What do you use the final product for?

2. What is the maximum input size of the raw material in mm or inch?

3. What is the product’s size do you want in micron or mesh?

4. What is the capacity (t/h) do you want?

5. What do you use the final product for?