New Model SMD CHARMHIGH TS10 10 Heads Pick and Place Machine Surface Mount Robot LED Electronic Components Light Making

US $35,000.00 / piece

1 piece(s)Minimum order

weight (kg):

1700

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

Gear, Pump, motor

place of origin:

China

brand name:

CHARMHIGH

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| weight (kg) | 1700 |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | Gear, Pump, motor |

| place of origin | China |

| brand name | CHARMHIGH |

| model number | TS10 |

| warranty | 1 Year |

| Weight | 1930kg |

| Vacuum Generation | Built-in vacuum pump |

| Mounting Head Quantity | 10 |

| Mounting Speed | 42000cph (optimal) |

| Component Height | ≤12mm |

| Feeders | 100 8mm standard feeder stacks |

Product Detail

Overview

If you need a high-speed, high-precision, stable pick and place machine, please choose CHARMHIGH!

If you need a pick and place machine with super cost-effectiveness, please choose CHARMHIGH!

If you need a SMT production line that best suits your company , please choose CHARMHIGH!

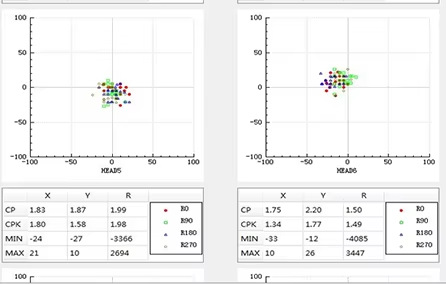

Supporting CPK is an important key to choosing a pick and place machine, making the SMT production process more stable.

ANC: nozzles can be automatically allocated according to components, making SMT production more intelligent and more efficient.

High-precision universal mounting head: one machine can meet the mounting needs of various components with high stability

Cast iron base structure, the pick and place machine runs smoothly at high speed.

Driven by dual servo motors, mounting accuracy is guaranteed.

For more advantages, please consult or leave a message online...

TS10 High speed, high precision and multi-function 10 head

Pick and Place Machine Specifications

Dimensions | 1600mm(L)×1688mm(W)×1560mm(H) |

Weight | 1930kg |

Supply | AC380V (50Hz, three phase), 4.5kW |

Air Supply | 0.5MPa ~0.7MPa |

Vacuum Generation | Built-in vacuum pump |

Mounting Head Quantity | 10 |

Mounting Speed | 42000cph (optimal) |

Mounting Accuracy | (XY)±0.035mm CPK≥1.0 |

Component Height | ≤12mm |

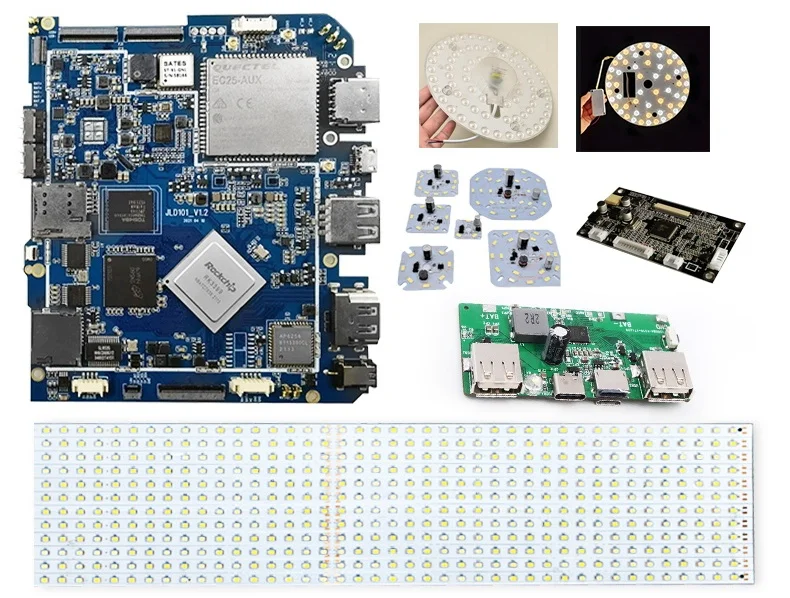

Component Type | 01005/0201/0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc. (resistor/capacitor/diode/triode/LED/IC, etc.) |

Component Range | Inch size 0201 to 36mm*36mm, and larger components mounting. |

PCB Thickness | 0.6mm~3.5mm |

PCB Size | 600mm(L)×400mm(W) (standard); 1200mm(L)×400mm(W) (optional) |

PCB Conveying | 3-section-rail automatic conveying, PCB support |

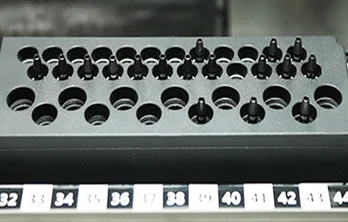

Nozzle Change | Automatic nozzle change (37-hole nozzle library) |

Control System | Built-in industrial computer (Windows 7) equipped with monitor, keyboard, and mouse |

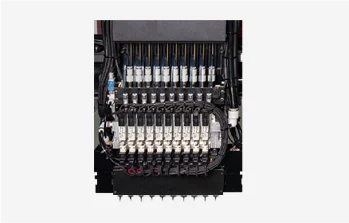

Drive System | X&Y axis driven by Panasonic A6 servo motors (Y axis by double motors); adopting flexible S-curve acceleration and deceleration |

Transmission System | X&Y axis adopting THK ground ball screw and THK mute linear guide (Y axis with double screws) |

Feeding System | 100 NXT 8mm standard feeder stacks (also suitable for IC tray and stick feeder) |

Vision System | Fly camera×10 (component size applicable: 16mm×16mm); IC camera×1 (component size applicable: 36mm×36mm); It has the function of image stitching Mark camera×2 |

Company Profile

Charmhigh was established in 2009 and has a history of 15 years. We mainly focuses on the research and development, manufacturing and sales of SMT P&P machines and provide customers with one-stop SMT solutions.We currently has our own industrial park, which is mainly divided into: R&D center, manufacturing center, sales center, etc. The site size is nearly 40,000 square meters. The products are exported to various countries and are deeply trusted by users.

Why Choose Us

1.CHARMHIGH is chosen by customers in more than 30 countries around the world.

2. We have rich experience in SMT factory settings and are good at customizing various SMT manufacturing solutions and services for customers from scratch.

3. We can provide the most professional technical services and support.

4. We have rich experience in dealing with SMT issues and solutions.

5. Choosing CHARMHIGH will definitely become your reliable Chinese partner.

CPK usually represents the process capability of the pick and place machine.Supporting CPK ensures that the equipment can work stably and accurately within the required range of accuracy.

37-hole nozzle library, automatically changes nozzles according to the different components, making your SMT production more intelligent and automatic, and improving production efficiency.

Ensure the accuracy and stability of the pick and place machine when working at high speed.Solve the problem of easy wear of angular swing torque generated by single motor drive.

Meets the needs of mounting various components and don't need to replace the mounting head.

Component mounting range: 0201-36mm*36mm.

Advanced basic structure, grinding industrial-grade platform, and integrated Y-axis casting make the equipment stable and reliable at high speed

Based on advanced visual algorithms, it can clearly identify the number and characteristics of chip pins to ensure high-precision chip mounting. It also has segmentation and recognition functions to ensure the mounting of large components.

High-speed synchronous recognition of components within 16MM*16MM, achieving high-speed mounting.Each nozzle has independent detection function, making SMT production more reliable.

50 material stacks in front and back, using NXT feeder, feeding accuracy ±0.03 mm CPK≥1, fast feeding speed, high accuracy, effectively reducing material throwing.

Mounting Range:

Feeding System:

Feeding method: electric feeder is used for feeding, and the feeding accuracy reaches ±0.03mm CPK≥1.

Feeder feeding table: supports offline feeding in advance, saving working time.

Vibration feeder: support the feeding of tubular components.

IC tray: support TRAY feeding and bulk components feeding.

SMT Product Introduction

PCB load machine

Automatically transports PCB boards to the production line, and automatically and accurately delivers PCB boards to the next device by receiving the board request signal from the lower computer.

PCB Unload machine

Used to collect processed PCB boards, usually at the end of the SMT production line.

Solder paste printing machine

The working principle is to fix the PCB on the printing table, then use a scraper to print the solder paste through the steel mesh on the designated pad, and then transfer it to the pick and place machine through the track.

Multi-function universal pick and place machine

By importing the PCB coordinate file, locating the PCB origin and the material picking position, the surface mount components are accurately mounted on the PCB board through the nozzle of the mounting head.

SMT Conveyor

Used to connect devices in SMT production lines, with transmission and board stopping functions.

AOI

Automatic optical inspection uses high-speed and high-precision visual processing technology to automatically detect various mounting errors and welding defects on PCB boards.

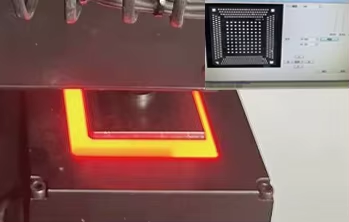

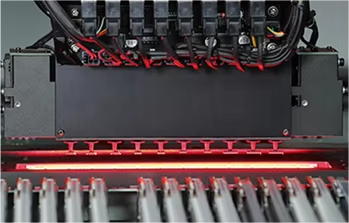

8- zone reflow oven

The solder paste is melted by heating to connect the components to the PCB boards, and then solidified by cooling. It is divided into preheating zone - constant temperature zone - reflow zone - cooling zone.

Feeder

Tape feeder, tube feeder, tray feeder. Used for feeding packaged components on SMT machine

Packing & Delivery

Our Company

FAQ

1. What can we do for you?

A: Various SMT equipment (such as pick and place machines, solder paste printers, reflow oven) and SMT one-stop services and solutions, professional after-sales service and technical support.

2. Are you a trader or manufacturer?

A:We are a professional pick and place machine manufacturer in China for 15 years.

3. How many days is the delivery date?

A:Normally all our products are in stock and will be shipped within 15 days after payment is received.

4. Why choose us!

China's leading SMT equipment manufacturer, providing professional and timely services.

5. What are the payment terms?

Down payment of 30%, paid before shipment.