Plastic Price Steglassag Grinding Machine Industrial Limestone Powder Lead Grinding Rotary Ball Mill

US $4,900.00-15,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Bearing, Gearbox, motor, Gear

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

1.1-3.5

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Bearing, Gearbox, motor, Gear |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1.1-3.5 |

| Place of Origin | Henan, China |

| Brand Name | SHIBO |

| Dimension(L*W*H) | 900*3000 |

| Weight | 4.6 KG |

| Warranty | 1 year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Name | Industrial limestone powder lead grinding rotary ball mill for sale |

| Feeding size(mm) | ≤20 |

| Output size(mm) | 0.075-0.89 |

| Weight of Ball(t) | 2.7 |

| Rotary Speed(r/min) | 38 |

| Color | Customerized |

| Keywords | grinding miller ball mill |

| Application | Ore |

| Certification | CE ISO |

Product Detail

The ball mill can process barite, coal slime, potassium feldspar, tungsten carbide, copper ore, slag, hematite, white ash, gold ore, aluminum powder, high alumina porcelain, iron powder, fluorite ore, aluminum powder paste, Steel slag, quartz sand, sulfuric acid slag, barite, clinker, bauxite, ceramsite sand, etc. dozens or even hundreds of ores.

Product Paramenters

Model | Ball load(t) | Feeding size(mm) | Discharging size((mm) | Capacity(t/h) | Motor power(kw) |

Φ900 x 1800 | 1.5 | ≤20 | 0.075-0.89 | 0.65 - 2 | 18.5 |

Φ900 x 3000 | 2.7 | ≤20 | 0.075-0.89 | 1.1- 3.5 | 22 |

Φ1200 x 2400 | 3 | ≤25 | 0.075-0.6 | 1.5- 4.8 | 30 |

Φ1200 x 3000 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 |

Φ1200 x 4500 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

Φ1500 x 3000 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 |

Φ1500 x 4500 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

Φ1500 x 5700 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 |

Φ1830 x 3000 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 |

Φ1830 x 4500 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

Φ1830 x 6400 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

Φ1830 x 7000 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

Φ2100 x 3000 | 15 | ≤25 | 0.074-0.4 | 6.5- 36 | 155 or 180 |

Φ2100 x 4500 | 24 | ≤25 | 0.074-0.4 | 8- 43 | 245 |

Φ2100 x 7000 | 26 | ≤25 | 0.074-0.4 | 8- 48 | 280 |

Φ2200 x 4500 | 27 | ≤25 | 0.074-0.4 | 9- 45 | 280 |

Φ2200 x 6500 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

Φ2200 x 7000 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

Φ2200 x 7500 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 |

Φ2400 x 3000 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 |

Φ2400 x 4500 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 |

Φ2700 x 4000 | 40 | ≤25 | 0.074-0.4 | 12-80 | 40 0 |

Φ2700 x 4500 | 48 | ≤25 | 0.074-0.4 | 12-90 | 480 |

Φ3200 x 4500 | 65 | ≤25 | 0.074-0.4 | According to the process conditions | 630 |

Φ3600 x 4500 | 90 | ≤25 | 0.074-0.4 | According to the process conditions | 10 00 |

Φ3600 x 6000 | 110 | ≤25 | 0.074-0.4 | According to the process conditions | 1250 |

Φ3600 x 8500 | 131 | ≤25 | 0.074-0.4 | 45.8 - 256 | 1800 |

Φ4000 x 5000 | 121 | ≤25 | 0.074-0.4 | 45 - 208 | 1500 |

Φ4000 x 6000 | 146 | ≤25 | 0.074-0.4 | 65 - 248 | 1600 |

Φ4000 x 6700 | 149 | ≤25 | 0.074-0.4 | 45 - 252 | 1800 |

Φ4500 x 6400 | 172 | ≤25 | 0.074-0.4 | 54 - 306 | 2000 |

Φ5030 x 6400 | 216 | ≤25 | 0.074-0.4 | 68 - 386 | 2600 |

Φ5030 x 8300 | 266 | ≤25 | 0.074-0.4 | 88 - 500 | 3300 |

Φ5500 x 8500 | 338 | ≤25 | 0.074-0.4 | 108 - 615 | 4500 |

Product Description

3-5 Ton Quartz Grinding Ball Mill 1200X3000 Ball Mill For Grinding Silica Sand

Ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

Details Images

Motor and reducer

Output gate and grate screen

Grinding media : High chromium steel balls

Working site

Packing and delivery

The machine is nude packing , motor and other accessories are packing in wooden box

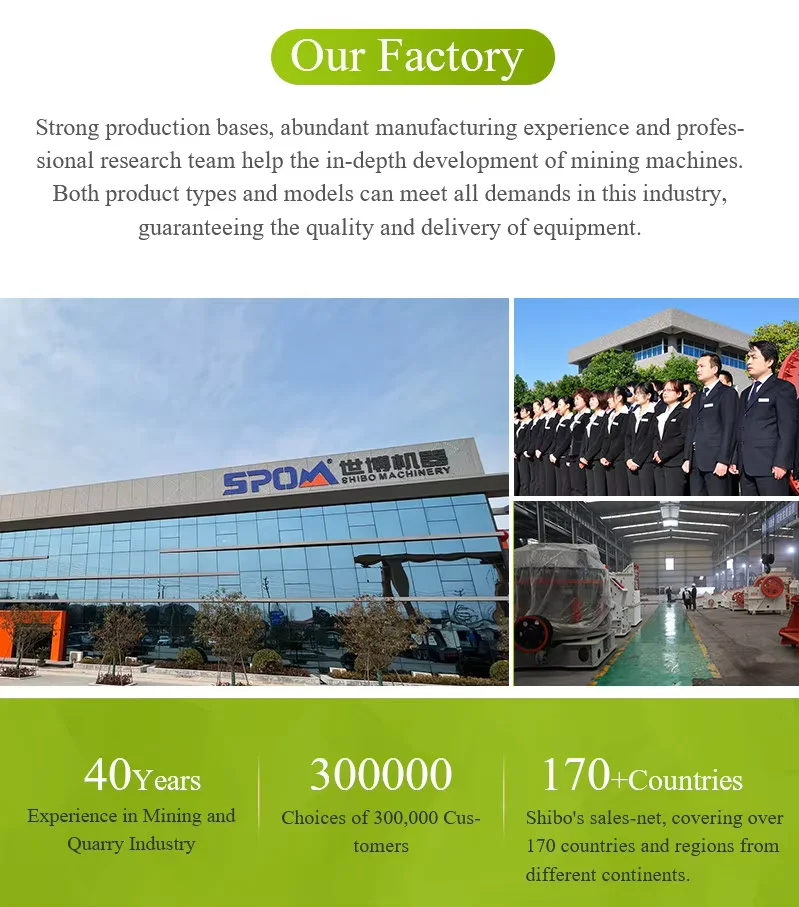

Company Profile

Customer Photos

After more than 30 years development , now we have more than 100 world markets and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

FAQ

Q: what is the payment terms ?

A: 30% prepayment by T/T , after the seller finish the production process and buyer verify the machine , 70% balance should paid before delivery, L/C is also acceptable .

Q: Which airport and train station is near to the factory ?

A: Zhengzhou xinzheng international airport and Zhengzhou East Railway Station

Q: How to choose the suitable model ?

A: please confirm the following information :

1. what kind of stone do you want to grinding ? such as gold ore ? limestone ?

2. what's the size of your stone before grinding ? how many inch or mm ?

3. what's your requirements of final product size ? how many mesh ?

4. what's your requirements of production capacity ? how many ton per hour ?

A: 30% prepayment by T/T , after the seller finish the production process and buyer verify the machine , 70% balance should paid before delivery, L/C is also acceptable .

Q: Which airport and train station is near to the factory ?

A: Zhengzhou xinzheng international airport and Zhengzhou East Railway Station

Q: How to choose the suitable model ?

A: please confirm the following information :

1. what kind of stone do you want to grinding ? such as gold ore ? limestone ?

2. what's the size of your stone before grinding ? how many inch or mm ?

3. what's your requirements of final product size ? how many mesh ?

4. what's your requirements of production capacity ? how many ton per hour ?