Professional Production and Sales Large Industrial Bag Dust Collector Customized Industrial Pulse Dust Collector

US $1,900.00-2,500.00 / unit

1 unit(s)Minimum order

condition:

New

place of origin:

Hebei, China

brand name:

Maona

weight:

1000 kg

warranty:

1 Year

Product name:

Industrial Dust Collector

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| condition | New |

|---|---|

| place of origin | Hebei, China |

| brand name | Maona |

| weight | 1000 kg |

| warranty | 1 Year |

| Product name | Industrial Dust Collector |

| Application | Industrial Dust Removal |

| Usage | Filter Industry Dust |

| Main function | Removing Industrial Dust |

| Material | Carbon Steel |

| Applicable Industries | Cement Plants, Flour Mills, Power Plants, Chemical, Building Material Shops, Manufacturing Plant, Energy & Mining, Construction works , Printing Shops |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Warranty of core components | 1 Year |

| Marketing Type | customized |

| Core Components | PLC, air ejector fan, Filter bag, Pulse valve, Ash unloading valve |

Product Detail

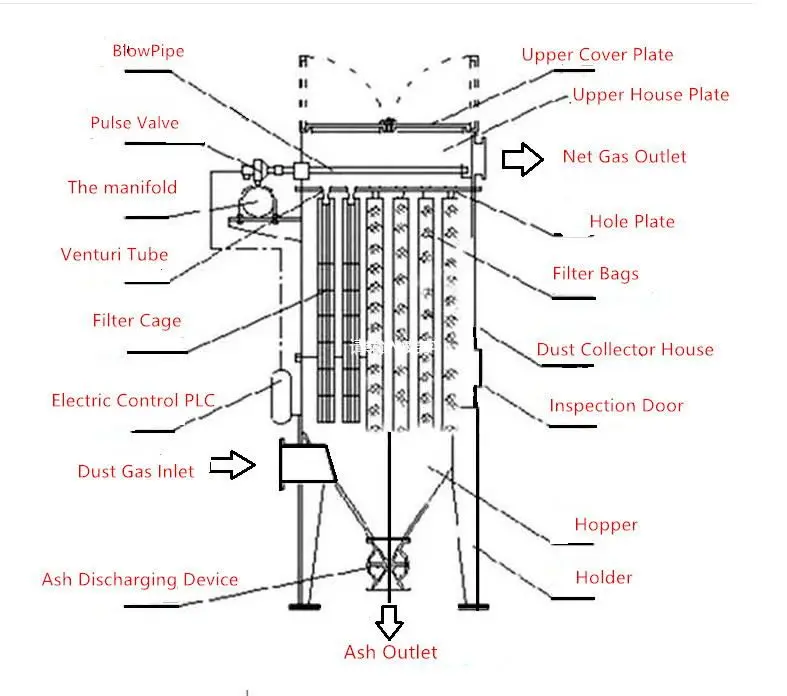

The dusty gas enters the equipment from the inlet of the dust collector and is evenly distributed to each filter bag through the action of the guide plate. The dust in the gas is blocked on its surface by the filter bag, while the purified gas passes through the filter bag and is discharged from the air outlet. Over time, dust accumulates on the surface of the filter bag, and when it reaches a certain thickness, it will affect the filtration effect. At this time, the filter bag is cleaned by the cleaning system, and the dust is shaken off into the ash hopper of the dust collector, and then discharged through the ash discharge device

HMC series pulse bag dust collector is a stand-alone bag dust collector. It adopts circular filter bag, self-closing ventilation

system and pulse jet dust cleaning method, which has the advantages of high dust removal efficiency. It has high dust removal

efficiency, good dust cleaning effect, low operating resistance, long service life of filter bags, simple maintenance, and stable

operation.

system and pulse jet dust cleaning method, which has the advantages of high dust removal efficiency. It has high dust removal

efficiency, good dust cleaning effect, low operating resistance, long service life of filter bags, simple maintenance, and stable

operation.

Component

1. Box: It is the main part of the bag dust collector, which supports and accommodates components such as filter bags and dust

cleaning systems. The box is usually welded from steel plates and has sufficient strength and sealing.

cleaning systems. The box is usually welded from steel plates and has sufficient strength and sealing.

2. Filter bag: It is the core component of the bag dust collector, and its material and quality directly affect the dust removal effect. Common filter bag materials include polyester fiber, glass fiber, PPS (polyphenylene sulfide), etc. Choose the appropriate filter bag according to different dust properties and working environments.

3. Dust cleaning system: used to remove the accumulated dust on the surface of the filter bag and ensure the normal operation of the

dust collector. The main methods of dust cleaning include pulse jet cleaning, back blowing cleaning, and mechanical vibration cleaning.

4. Ash discharge device: The collected dust is discharged from the dust collector, usually using methods such as screw conveyor, scraper conveyor, or pneumatic conveying

Item | value |

Applicable Industries | Manufacturing plants, food and beverage plants, construction projects, mining plants, cement plants, steel plants, chemical plants, glass plants, flour mills |

Core Components | Box body, filter bag, fan, pulse valve, ash discharge valve |

Application | Industrial Dust Removal |

Material | Carbon Steel |

Q1. Are you manufacturer or trade company ?

We are professional manufacturer in China , and have in this line almost 10 years .

Q2. Would it be possible for us to visit your factory ?

Sure, welcome you at any time !

Q3 . Will your company supply samples ?

Yes ,we do .

Q4. How can we get the quotation ?

Please let us know the specifications , such as the material ,micron ,apply in which industry etc .

Q5.what’s the lead time ?

Usually is 5-15 days after we received your payment .

Q6 . what is the packaging ?

Inner packing –poly bags .Outer packing –Export cartons .

Q7. Can I get your products with our logo and design ?

Yes ,you can . Most of our products can be customized according to your requirements .

Q8. Which payment terms are you accept ?

T/T , L/C .Western Union , Money gram are available for us . we accept 30% T/T in advance , the balance should be paid before

shipping .

We are professional manufacturer in China , and have in this line almost 10 years .

Q2. Would it be possible for us to visit your factory ?

Sure, welcome you at any time !

Q3 . Will your company supply samples ?

Yes ,we do .

Q4. How can we get the quotation ?

Please let us know the specifications , such as the material ,micron ,apply in which industry etc .

Q5.what’s the lead time ?

Usually is 5-15 days after we received your payment .

Q6 . what is the packaging ?

Inner packing –poly bags .Outer packing –Export cartons .

Q7. Can I get your products with our logo and design ?

Yes ,you can . Most of our products can be customized according to your requirements .

Q8. Which payment terms are you accept ?

T/T , L/C .Western Union , Money gram are available for us . we accept 30% T/T in advance , the balance should be paid before

shipping .