S1000L Competitive Price High-productivity Large Extrusion Blow Molded Parts for Amusement Park Blow Molding Machine

Other recommendations for your business

Contact us

Quik Detail

| video outgoing-inspection | Provided |

|---|---|

| machinery test report | Provided |

| core components | PLC, Pump, Bearing |

| plastic processed | PP, HDPE, PE |

| place of origin | Zhejiang, China |

| brand name | JUNENG |

| voltage | optioned |

| dimension(l*w*h) | 11*6*7 |

| clamping force (kn) | 1700 |

| plc brand | Siemens |

| screw l/d ratio | 28 |

| screw diameter (mm) | 135 mm |

| output (kg/h) | 240 kg/h |

| automation | Automatic |

| No. of Screw Heating Zone | 6 |

| screw heating power(kw) | 10 kW |

| extruder motor power(kw) | 350 kW |

| mold platen size(width)(mm) | 1400 mm |

| mold platen size(height)(mm) | 1600 mm |

| air pressure(mpa) | 0.8 MPa |

| air comsumption(m³/min) | 3.0 m³/min |

| die head heating power(kw) | 35 kW |

| power (kw) | 130 |

| weight (t) | 55 |

| key selling points | Long Service Life |

| warranty | 1 Year |

| model number | JN-S1000L |

| After-sales Service Provided | Service Machinery Overseas |

| Blow Moulding Type | Extrusion Blow Moulding |

| Servo Motor | PHASE |

| Frequency Converter | INOVANCE |

| Oil Pump | SUMITOMO |

| AC Contactor | FRANCE SCHNEIDER |

| Motor Driver | TAIWAN DELTA |

| Blowing Value | TAIWAN AIRTAC |

| Air Value | TAIWAN AIRTAC |

| Oil Seal | UK Sealtech |

| Condition | New |

| Warranty of core components | 1 Year |

| Application | Bottle |

| Applicable Industries | hotels, Farms |

| Showroom Location | Egypt, Mexico, Morocco |

| Year | 2024 |

| Accumulator Capacity(L) | 36 L |

Product Detail

Plastic extrusion blow moulding machine

Do the best for customers!

listening to the customer is what we are following consistently.

Clients oriented service,None-stop perfection.

JUNENG machine located in HUANGYAN ZHEJIANG.

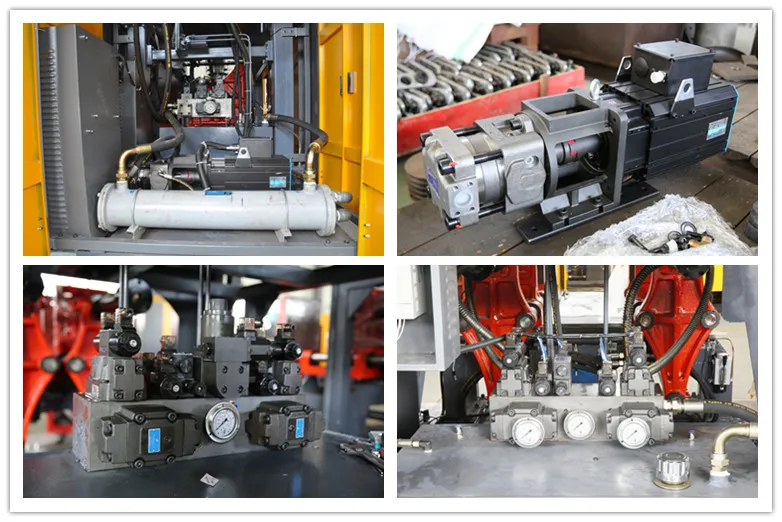

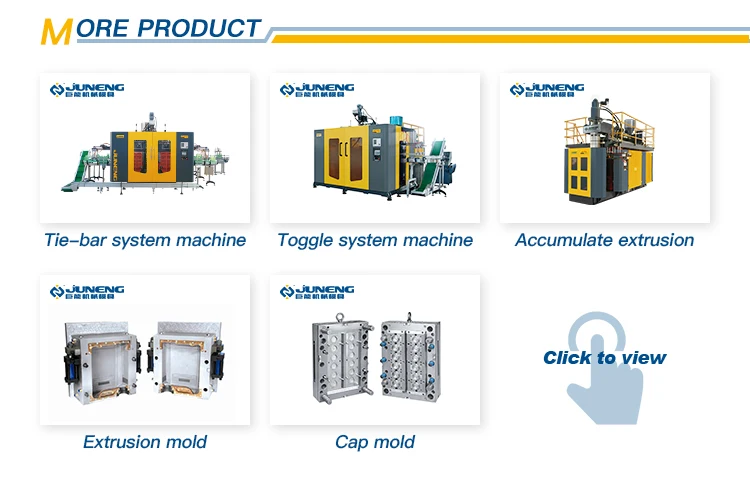

Our company introduce overseas advanced technology, formed a research and development team with many experts, engineers and technicians, to ensure the high quality products.Our company specialized in designning and producting many series and sizes extrusion blow molding machines, full automatic stretch blow molding machines and semi automatic blow molding machines.We can produce many kinds of plastic extrusion productions range from 5ml to 260 liters.We can supply the die-mold, like the single cavity die-mold, double cavities die-head,three cavities die-head, four cavities die-head and six die-head, we can also supply single layer,double layer and so on.We have thousands of machinery debugging experience.

Our company not only won the ISO certification, and all of our products have passed CE international certification.

Machine general specification:

| Extrusion Blow Moulding machine | |

| Model | JN-S1000L |

| Mold Cavities/die-head | According to the sample |

| Number of layer | optioned |

| Parison Programmer | As your need |

| Transparent line | Including |

| Capacity | According to the sample |

| Material | PE/PP/PVC |

| Max product volume (L) | 1000 |

|

Dry cycle (pc/hr) |

250 |

| Screw diamter (mm) | 135 |

| Screw L/D ratio (L/D) | 28~32 |

| Screw motor power (KW) | 110~132 |

| Screw heating capacity (kw) | 10*6 |

| No.of heating zone (zone) | 6 |

| Output of HDPE (kg/hr) | 300~350 |

| Oil pump driver power (kw) | 48 |

| Clamping Force | 1700 |

| Mold stroke (mm) | 1100~2500 |

| Size of mold w*h (mm) | 1400*1600 |

| Moving distance (mm) | 2400 |

| Max die diamter (mm) | 750 |

| Die heat capacity (kw) | 35 |

| Blowing pressure (mpa) | 0.8 |

| Air volume (m3/min) | 3.0 |

| Cooling water pressure (mpa) | 0.3 |

| Water consumption (L/min) | 250 |

| Weight of machine (ton) |

55 |

| Size of machine (m) | 11*6*7 |

Plastic extrusion blow moulding machine

Do the best for customers!

listening to the customer is what we are following consistently.

Clients oriented service,None-stop perfection

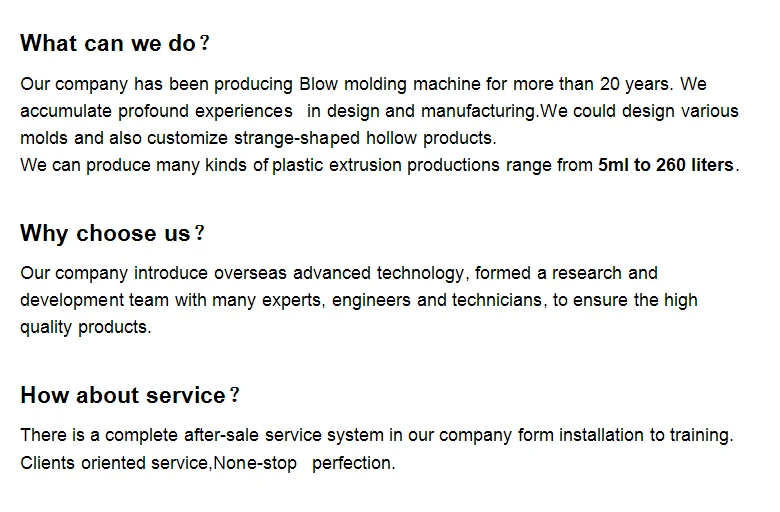

Machine details:

1--PLC,touch screen,screw and die head

2--Blowing part(blow pin & blowing valve),deflashing

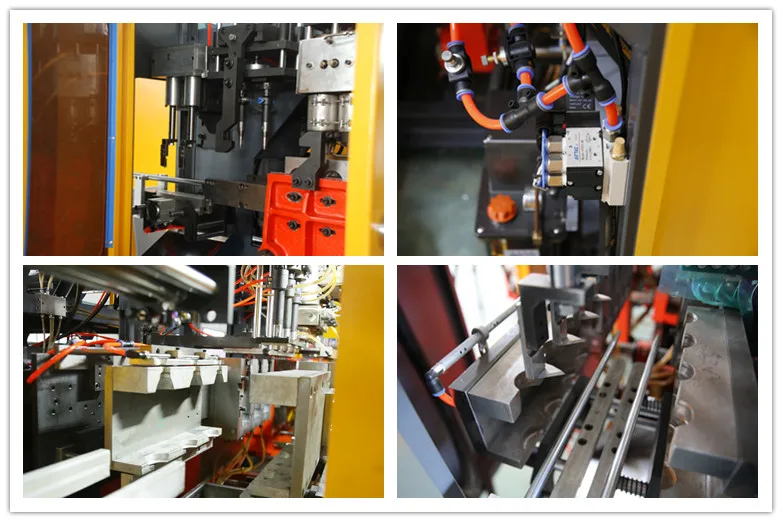

3--MOTOR & MAIN VALVE

Workshop:

Mould workshop:

blow molding machine

All the equipments, moulds(except the blowing moulds) and auxiliaries supplied by our company, we will provide all of the techniques and technology, and supply free install and adjusting operation, ensure the technology reliability and rationality.

You have two choices,One is your technical people come to our company, we teach your person how to operate the machine, how to maintain it and so on, but all of the cost should be paid by yourself.

Two is we supply engineer to you, you provide the cost of the visa, passenger tickets(round-trip ticket), room and board. Beside you need pay our person 100USD per day, and also we will pay our person. The place is supplied by yourself.