Simple Horizontal Shaft Mortar Mixer Adhesive Ceramic Wall Making Plant

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, motor, Gear |

| Application | dry mix mortar plant |

| Place of Origin | Henan, China |

| Brand Name | BH |

| Voltage | Customized 220V/380V/415V |

| Power | 10-15KW |

| Dimension(L*W*H) | Customer |

| Weight | 1200 kg |

| Features | Horizontal type |

| Warranty | 1 Year |

| Key Selling Points | Easy to Operate |

| Product name | Simple horizontal shaft mortar mixer adhesive ceramic making plant |

| Production Capacity | 3-4 T/H |

| Type | Simple dry mortar production line |

| End Product1 | tile adhesive mortar,wall putty mortar,skim coat mortar, |

| End Product2 | anti-crack mortar,waterproof mortar,self levelling, tile grout mortar |

| Cost | Small investments |

| Keyword | horizontal shaft mortar mixer and adhesive ceramic wall in spain |

| Mixer type | Horizontal Ribbon Mixer |

| Advantage | Professional Manufacture |

| Color | Customized Color |

Product Detail

Simple horizontal shaft mortar mixer adhesive ceramic wall making plant

| Description of BH Simple dry mortar plant |

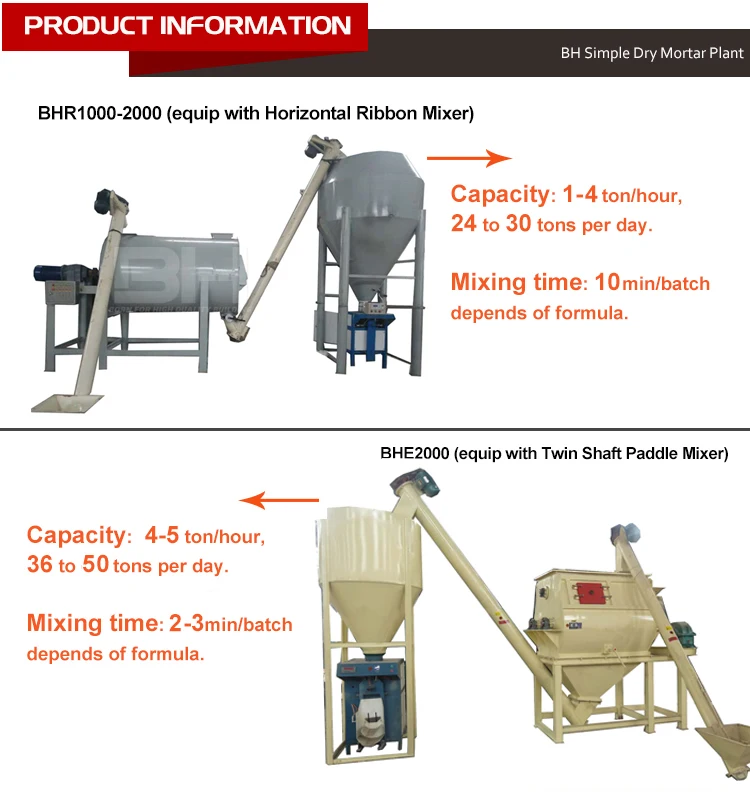

BH simple dry mortar plant can equip with two kinds of mixers,horizontal ribbon mixer and twin shaft paddle mixer according to customer requested capacity and actual workshop height condition. 1-4t/h BHR series simple dry mortar plant usually equip with horizontal ribbon mixer,4-5t/h BHE2000 simple dry mortar plant usually equip with twin shaft paddle mixer.Both these two mixer machine can produce Putty powder, Tile adhesives,tile glue, Thin set coating, Masonry mortar, Plaster mortar, Screed mortar,Bonding mortar,AAC jointing mortar, dry sand mixture, Insulation mortar,Decoration mortar and etc.

BH Simple dry mortar plant features

1. BHR series Horizontal ribbon mixer plant height is less than 3.2 meters, BHE series twin shaft paddle mixer plant height is less than 4.2 meters, both occupation area 15~ 20 square metres , ordinary houses can be use as factory production, this solve the problems of traditional dry mortar production line has to increase height of factory.

2. It achieve function of manual batching raw materials, automatic mixing, automatic filling and packing at 15-50kg/bag , under a small investment, and less labor.

3. It is one of the most simple and practical dry mortar production line.

BH Horizontal Ribbon Mixer Working principle:

The outer and inner screw ribbon blade driven by high speed rotating shaft,mixing the material in maximum,inner screw ribbon blade forced the material to sides,outer screw ribbon blade forced sides material to inward,mix the materials back and forth.In the same time,some material driven by screw ribbon do the radial motion,to form the convective mixing,so to achieve uniform mixing effect in relatively short time.

BH Twin Shaft Paddle Mixer Working principle:

The high efficiency twin shaft mixer adopts the paddle structure,The materials can lose weight instantly at the critical parabolic rotate speed so that can achieve best mixing effect,while the violent turnover speed shortens the mixing time in large extent,Thus the mixer is widely applied in medium and large dry mortar production lines

|

|

|

|

|

| Model | Simple dry mortar plant | Improved Simple dry mortar plant | Semi automatic dry mortar plant | Full automatic dry mortar plant |

| Out put | 1-3t/h | 4-5t/h | 5-8t/h | 10-30t/h |

| Components |

screw conveyor, horizontal ribbon mixer, storage tank, packing machine, control cabinet, air compressor |

screw conveyor, twin shaft mixer, storage tank, packing machine, control cabinet, air compressor | bucket elevator, twin shaft mixer, holding tank, packing machine, control cabinet, air compressor | cement silo, screw conveyor, automatic weighing system, bucket elevator, premix tank, twin shaft mixer, holding tank, packing machine, automatic control cabinet, air compressor |

| Occupied area | 20m² | 20m² | 50-60m² | 60-100m² |

| Total power | 5.5-7.5kw | 6-11kw | 24-28kw | 60-120kw |

|

Mixer volume |

3300*1050*2100(mm) | 2m³ | 2m³ | 2m³, 3m³, 4m³ |

| Equipment height | 3-4m | 3-4m | 6-8m | 8-13m |

| Man power | 2-3person | 2-3person | 3-4person | 3-4person |

| Batching and packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Automatic batching & Automatic packaging |

| MAIN PARTS FEATURES |

|

Horizontal Ribbon Mixer 1.Occupy area<20m2,height 3.5m,required 2-3 operation. |

|

Twin Shaft Paddle Mixer 1. High mixing homogeneity at 99.9% 2. High efficiency at 90~120 seconds per batch 3. No dead corner for mixing. No residual for discharging 4. Durable lifetime and stable performance. |

|

|

Packing Machine |

|

Screw conveyor |

|

PACKAGING & DELIVERY

Packaging

1, HS code can be supplied to you for checking importing tax in your country.

2, Standard export packaging by container, which should be applicable to international requirement.

3, Big size equipment will be fixed by steel wire, while small ones together with spare parts will be packed into wooden boxes.

4, Standard configuration: 2X40HQ container for 1 set 10t/h dry mortar plant.

Shipping

Usually by sea, sometimes by land, air.

Delivery time: 15-30 days after deposit arrived

The reason you choose us:

» The structure we designed is advanced and compact. According to your site and capacity, we can provide you reasonable design with factory price.

» Cooperated with Shanghai WEIPU Institute (www.weipuchem.com),then we supply advanced construction materials formula and top rank additives together to ensure the end products good quality you produce.

» Our professional installation team has rich experience to complete the installation, commissioning fast, and also to train workers how to operate, maintain the equipment.

» As a professional and highly experienced manufacturer of dry mortar mixing equipment, rotary dryers and kiln, grinding mill equipment, building materials processing equipment in China for more than 20 years. We are in the leading position in this scopes.

Q: For providing you the suitable quotation we need to know the following information:

1. What capacity do you need?

2. How many raw materials you use? What's the estimate ratio?

3. Is sand dryer required in this system? What is the fuel you use, coal? gas or diesel?

4. Regards packing, how many kg per bag do you need?

Q:What equipment and services you can provide?

We can provide you turnkey solution of dry mortar manufacturing machine from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after-sales services, life time technical support etc .

Q: What about Warranty of the products?

The BH Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us. During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

If you want to know more of our dry mortar manufacturing machine, please send us inquiry or contact us directly.