Small Calcite Raymond Mill Mining Stone Powder Making Machine 3r Stone Grinding Raymond Roller Grinding Mill Price

US $2,800.00-4,100.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

motor, Engine, Bearing

Type:

Raymond Mill

Motor Type:

AC Motor

Capacity(t/h):

10

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | motor, Engine, Bearing |

| Type | Raymond Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 10 |

| Place of Origin | Henan, China |

| Brand Name | Rongde |

| Dimension(L*W*H) | according to the product |

| Weight | 1200 KG |

| Warranty | 1 Year |

| Product name | Limestone Powder Making Machine Raymond Grinder Mill Plant |

| Device Type | 3R,4R,5R |

| Max. Input Size (mm) | 15-30 |

| Output Size (mm) | 0.125-0.044 |

| Application Materials | Ores and rocks include granite limestone metal ore construction waste |

| After-sales service | Online video or dispatch after-sales team |

| Advantages | High Efficiency |

| Accessories Supply | Anytime |

| Factory Visit | Welcome to visit |

Product Detail

Small calcite raymond mill mining stone powder making machine 3r stone grinding raymond roller grinding mill price

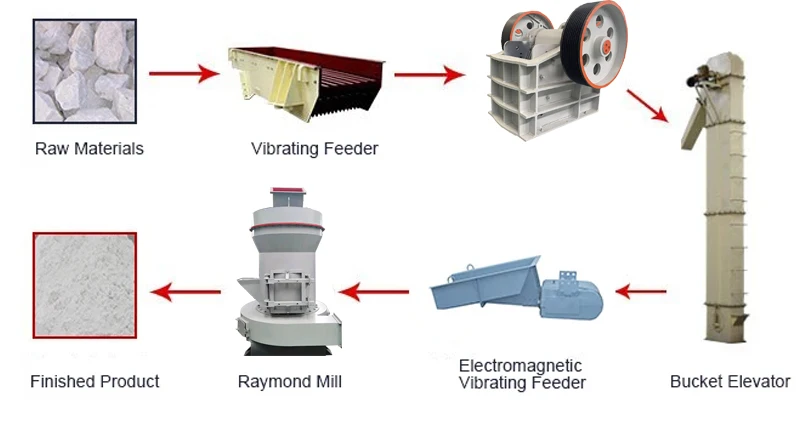

What is Raymond Mill?

Raymond mill is a commonly used industrial grinding equipment, which has become a powder-making equipment widely used in mining, metallurgy, building materials, chemical industry, ceramics, power, and other industries.

Raymond Mill has many advantages such as high efficiency and energy saving, high and uniform finished product fineness, high screening rate, strong adaptability, easy operation, small footprint, good environmental performance, and a high degree of automation.

Raymond mill is a commonly used industrial grinding equipment, which has become a powder-making equipment widely used in mining, metallurgy, building materials, chemical industry, ceramics, power, and other industries.

Raymond Mill has many advantages such as high efficiency and energy saving, high and uniform finished product fineness, high screening rate, strong adaptability, easy operation, small footprint, good environmental performance, and a high degree of automation.

Application scenarios of Raymond Mill

The particle size range of Raymond mill finished products is usually between 80-320 mesh (0.019mm~0.0038mm), and the maximum fineness of some materials can reach 1000 mesh (0.013 mm).

Raymond mill is widely used in quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, manganese ore, titanium ore, copper ore, chromium ore, and other mineral industries.

The particle size range of Raymond mill finished products is usually between 80-320 mesh (0.019mm~0.0038mm), and the maximum fineness of some materials can reach 1000 mesh (0.013 mm).

Raymond mill is widely used in quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, manganese ore, titanium ore, copper ore, chromium ore, and other mineral industries.

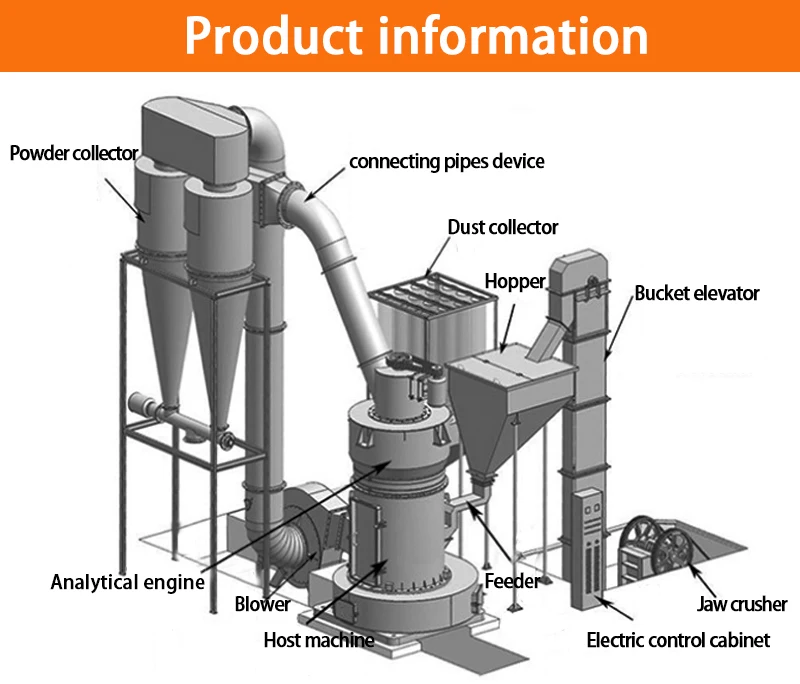

Main structure of Raymond mill

The Raymond mill is mainly composed of the main machine, analyzer, fan, finished product cyclone separator, micro powder cyclone separator and air duct. Among them, the main machine is composed of the frame, air inlet volute, scraper, grinding roller, grinding ring, cover and other parts. After the material is ground, the wind force of the fan blows up the powder, and it is sorted by the analyzer. The material with too coarse fineness will fall back into the grinding chamber for grinding, and the material with fineness that meets the specification will enter the cyclone collector with the wind flow and finally become the finished product.

The Raymond mill is mainly composed of the main machine, analyzer, fan, finished product cyclone separator, micro powder cyclone separator and air duct. Among them, the main machine is composed of the frame, air inlet volute, scraper, grinding roller, grinding ring, cover and other parts. After the material is ground, the wind force of the fan blows up the powder, and it is sorted by the analyzer. The material with too coarse fineness will fall back into the grinding chamber for grinding, and the material with fineness that meets the specification will enter the cyclone collector with the wind flow and finally become the finished product.

Product Paramenters

Model | Roller Size (mm) | Max. Input Size(mm) | Output Size (mm) | Capacity (t/h) | Power (kw) | L*W*H (mm) |

3R1510 | 150*100 | 15 | 0.044-0.125 | 0.8-8 | 7.5 | 3250*1220*3830 |

3R2115 | 210*150 | 15 | 0.044-0.125 | 1-10 | 15 | 3520*3350*4550 |

3R2615 | 260*150 | 20 | 0.044-0.125 | 1.5-15 | 18.5 | 4650*3620*5130 |

3R2715 | 270*150 | 20 | 0.044-0.125 | 2-25 | 22 | 4750*3620*5130 |

3R3015 | 300*150 | 25 | 0.044-0.125 | 2-30 | 30 | 5360*4170*5240 |

4R3016 | 300*160 | 25 | 0.044-0.125 | 3-35 | 30 | 5450*4120*5250 |

4R3216 | 320*160 | 25 | 320*160 | 4-45 | 37 | 7120*5940*7930 |

Features:

1. The discharge fineness can reach 0.044 mm, meet different processing requirements.

1. The discharge fineness can reach 0.044 mm, meet different processing requirements.

2. High efficiency and energy saving. Closed circulation system , less energy waste.

3. Fully enclosed gear transmission, smooth operation.

4. Centralized control, the grinding workshop can basically realize unmanned operation.

5. Vertical structure, small footprint.

5. Vertical structure, small footprint.

Customer Site

Packaging&Delivery

FAQ

1. Are you manufacture or trading company?

We are factory.

2. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment.

4. How long is the warranty? Does your company supply the spare parts?

One year. Spare parts for you at lowest cost.

5. If I need the complete crushing plant can you help us to build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.