Stainless Steel Mini Small Spice Hammer Mill

Other recommendations for your business

Contact us

Quik Detail

| output (kg/h) | 10 - 600 kg/h |

|---|---|

| feeding size (mm) | 1 - 15 mm |

| output size (mesh) | 5 - 80 mesh |

| power (kw) | 7.5 |

| range of spindle speed(r.p.m) | 1000 - 4400 r.p.m |

| material | SUS304, SUS304L, SUS316, SUS316L |

| application | Chemicals Processing, Plastics Processing, Food Processing |

| type | Pulverizer |

| Product Type | spices |

| place of origin | Jiangsu, China |

| brand name | Doing Machine |

| voltage | 380V,50Hz,3P |

| dimension(l*w*h) | 900x700x1440mm |

| weight (kg) | 350 KG |

| warranty | 1 Year |

| key selling points | Multifunctional |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | Bearing, motor, Gearbox |

| Type | Hammer mill |

| Application | Size reduction |

| construction material | SUS304 |

| Power supply | 240V/380V/415V |

| Dust collection | cyclone/bag filter |

| Condition | New |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Applicable Industries | Food & Beverage Factory, Chemical factory |

Product Detail

Main features

Working principle

Technical advantages

Model | FM-8 | FM-16 | FM-32 | FM-48 |

Capacity kg/h | 10-100 | 30-200 | 50-400 | 100-600 |

Input size mm | ≤10 | ≤10 | ≤15 | ≤15 |

Output size mesh | 12-120 | 12-120 | 12-120 | 12-120 |

Total power KW | 3 | 7.5 | 11 | 18.5 |

Rotation speed RPM | 2350/4360 | 1000/2400/4400 | 1000/2400/4400 | 1000/2400/4400 |

Installation dimension mm | 1050x600x1600 | 1100x860x1520 | 1280x950x1600 | 1380x1200x1750 |

Gross weight kg | 200 | 350 | 550 | 800 |

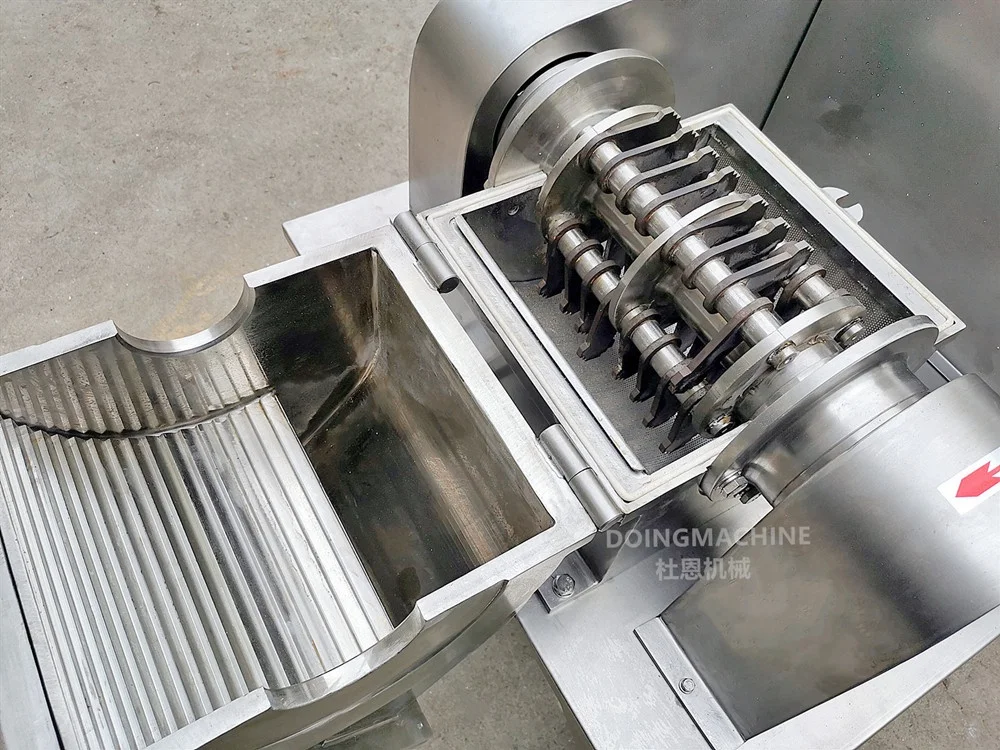

Knife blades

Dried spices

Chemical powder

Food agglomerates

Q: What information should be provided in order to get a proposal or quotation?

A: Our Fitz Hammer Mill can be specially designed for each customer according to specific material, capacity, feed material size and product size. Before we can work out a detailed proposal or quotation, we have to know the following information:

1) Detailed information of material are you going to grind. We may ask you to provide samples for grinding test.

2) Size of your material

3) Your required particle size after grinding

4) Grinding capacity in kg/h

Q: How the machine will be delivered ?

A: The system is usually dismantled into grinding unit, cyclone, bag house, draft fan and control cabinet for shipping. Each part is packed in box made by plywood.

Q: What kind of after sale service you can provide?

A: We have professional after sale service team who can reach you in short notice. They can supervise the installation, do commissioning and train your workers.