Strong Half Round Segment Tile Arc Trapezoidal Magnet Block Ndfeb Magnet N52 Curved Neodymium Magnet

100 piece(s)Minimum order

Place of Origin:

Guangdong, China

Brand Name:

OEM

Type:

Permanent

Composite:

Neodymium Magnet

Shape:

Custom

Application:

Industrial Magnet

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Place of Origin | Guangdong, China |

|---|---|

| Brand Name | OEM |

| Type | Permanent |

| Composite | Neodymium Magnet |

| Shape | Custom |

| Application | Industrial Magnet |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching, Moulding |

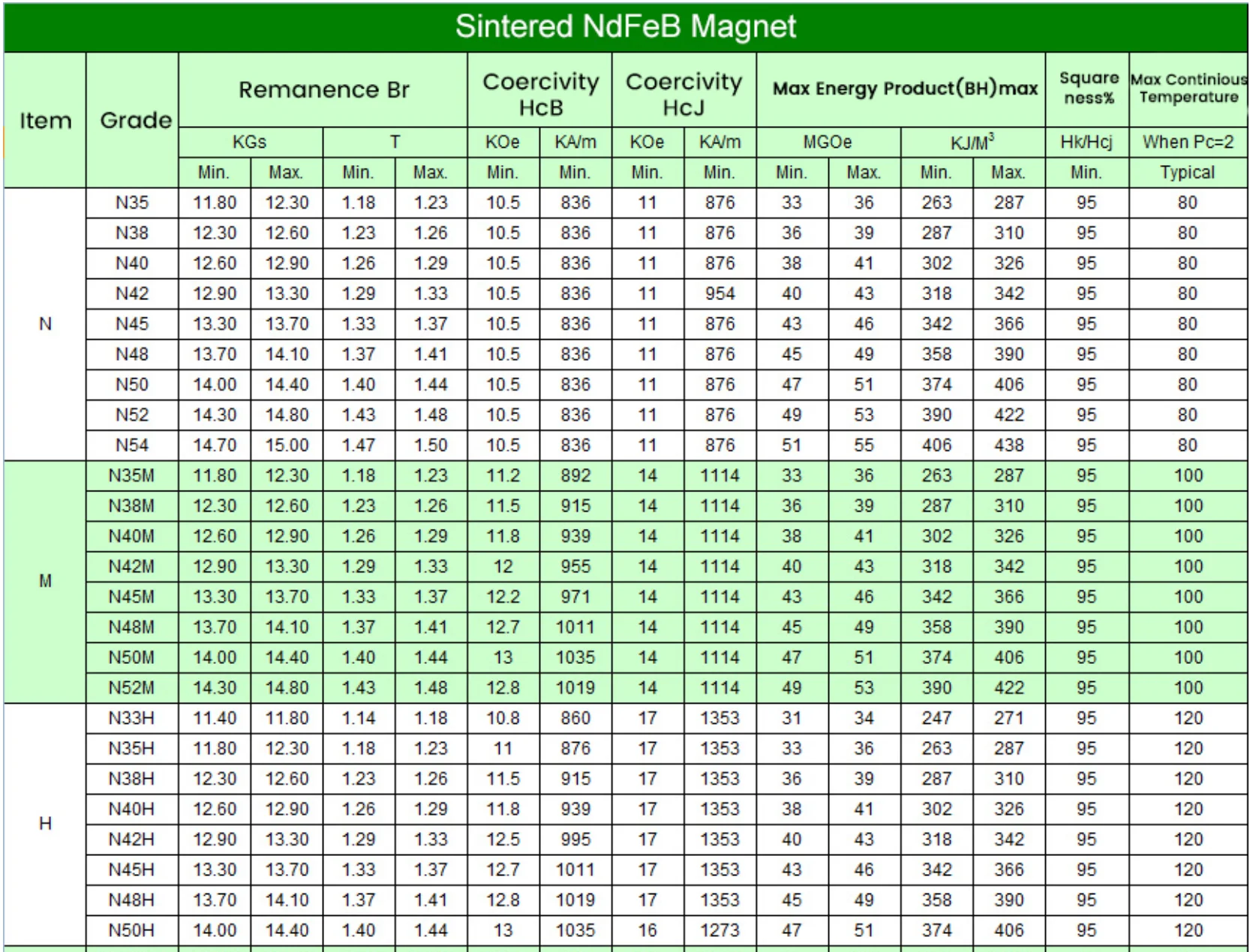

| Grade | NDFEB magnet, N32-N55 (M.H.SH.UH.EH.AH) |

| Delivery Time | within 7 days |

| Flux Index | 50kG²·mm² |

| Raw Material | Ndfeb Neodymium Magnet |

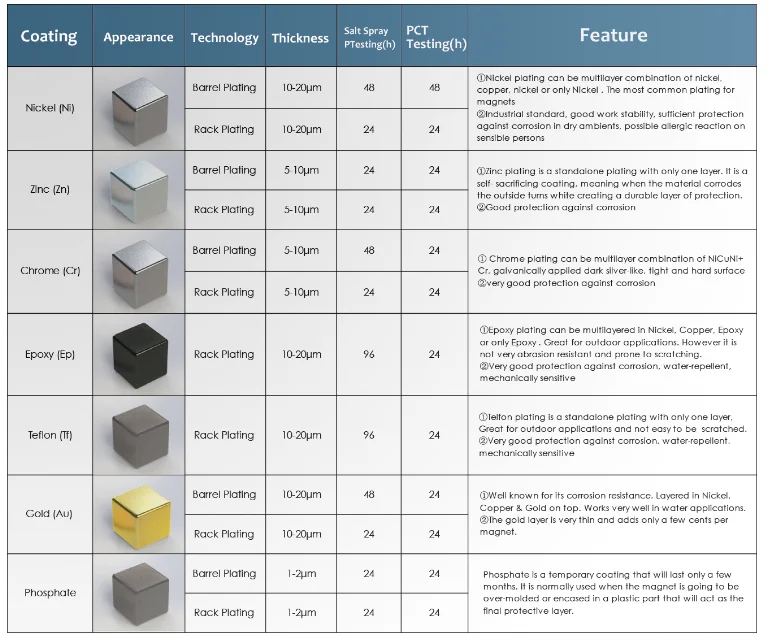

| Coating | Ni-Cu-Ni,Zinc,Epoxy |

| Processing | Sintered Permanent Neodymium Magnet |

| Sample | free provide |

| Grade BH | N52 (NM-EH ) |

| Packing | paper carton |

| Working Temperature | 80-220 Degree Centigrade |

| Density | 7.3-7.7 G/cm3 |

| Size | Customized Size |

Product Detail

Products Description

Material | Customized (N33 N35 N38 N40 N42 N45 N48 N50 N52 etc.) | ||||||

Coating | Ni-Cu-Ni,Nickel Customized (Zn,Ni-Cu-Ni,Gold, Silver, Copper, Epoxy, Chrome, etc) | ||||||

Shape | Custom (Block, Disc, Cylinder, Arc,Bar, Ring, Countersunk, Segment, Hook, Trapezoid) | ||||||

Custom Magnetic | Diametrally Magnetized,Axially Magnetized,Thickness Magnetized,Multi-poles magnetized,Radial Magnetized. (Customzied specific requirements magnetized) | ||||||

Company Profile

OEM- R&D Service

We are a set of production, research and development, sales in one of the national high-tech enterprises, specializing in the production of high-end tin-iron boron permanent magnet materials, with international

advanced production equipment and modern plant facilities, is one of the largest production enterprises in the permanent magnet industry

Quality Culture

The initial material meets the national quality standard. Complete the quality management system, strict monitoring of the production process to ensure product quality All finished products through the national testing department through Reach,ROHS certification, as well as through the ISO9001 quality system certification, in line with the EU environmental standards.

High performance

We can customize professional solutions for exclusive magnetic products according to your different needs. Ten years of persistence, exquisite production technology, excellence in design and research and development, meticulous quality management system mass production, delivery guarantee, price concessions.

Production Process

Product packaging

Why Choose Us

Customer Feedback

FAQ

Q: May we get a sample of the product? How to ship and how to pay ?

A: Yes,the samples testing should be necessary for first time , we would like cooperate for samples. If it's regular magnets and we have stock , we would like supply free samples for customers, if need new production , we will quote samples fee and we can accept T/T, Paypal , Western Union , Alibaba trade assurance for payment.We will send the sample to you by DHL express.

Q: What magnet materials are available?

A: There are many different magnet materials available, which we are able to provide. These include neodymium, samarium cobalt,alnico, ferrite, bonded neodymium, bonded samarium cobalt, bonded ferrite, injection molded neodymium, injection molded samarium cobalt, rubber stripping, and FeCrCu. If there is another material you wish to procure, please contact us.

Q:Can you supply custom magnets?

A: Yes, we have the capability to produce magnets to your specification in NdFeB, SmCo, AlNiCo, Ferrite, and rubberized magnet materials. You can contact us for more details .

Q:Do you have a minimum purchase order?

A: The manufacturing of magnets is a complex process, please check our production flow for more information. As considering the production time and cost, we suggest the batch order value should be more than US$3000 per time; Of course, if less than US$3000,we also would like quote our offer for your kind consideration, so we have no strict MOQ .

Q: How many days does it take to ship my order?

A: In generally, the sintering NdFeB and SmCo magnet production time is 15-25days, cast AlNiCo will take 25-30days , the magnetic assemblies will be about 30-40 days for your reference , the exact time need to be checked before the order .

Q:What elements affect the magnet price ?

A: 1. Shape and size : cylinder (DxH), cuboids(LxWxH) ,cubes, ring(ODxIDxH) belong to regular shape , arc magnets are popular used in motors or generators , before quotation and batch production , we have to confirm the technical drawing and samples, other irregular shape