Suspension T U Roll Forming Machine Steel Runner and Channel Producing Line

Other recommendations for your business

Contact us

Quik Detail

| Type | Roll forming machine |

|---|---|

| Tile Type | Galvanized steel |

| Use | Ceiling |

| Place of Origin | Tianjin, China |

| Dimension(L*W*H) | 4.5*0.8*1 m |

| Weight | 1500 kg |

| Warranty | 2 years, 2 year |

| Key Selling Points | Easy to Operate |

| Rolling thinckness | 0.3-0.8mm |

| Feeding width | As customer drawing |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Bearing, Engine, Gear, Gearbox, motor, PLC, Pressure vessel, Pump |

| Material type | galvanized steel |

| Export port | Tianjin port |

| Need container | 1*20 feet |

| Machine color | As customer' need |

| Control box language | As customer' need |

| Machine cutter material | Cr 12 |

| Roller material | Cr 12 |

| Length and piece measure | by counter |

| Control system | PLC(detla) System |

Product Detail

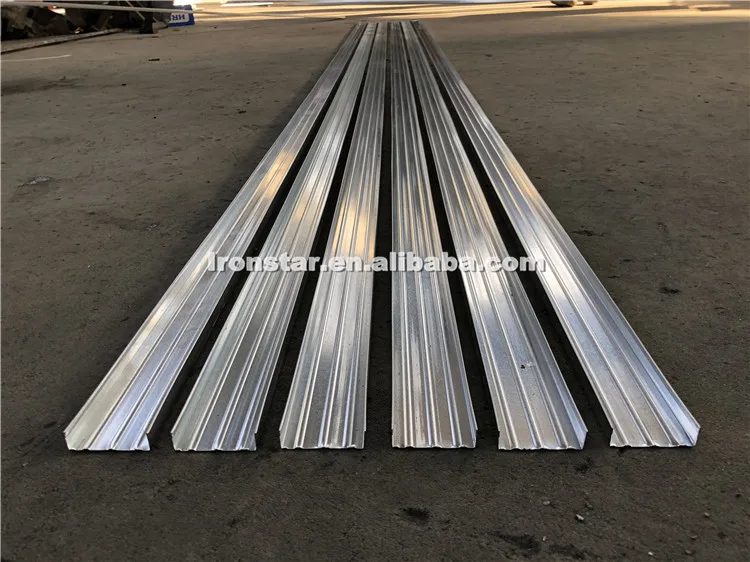

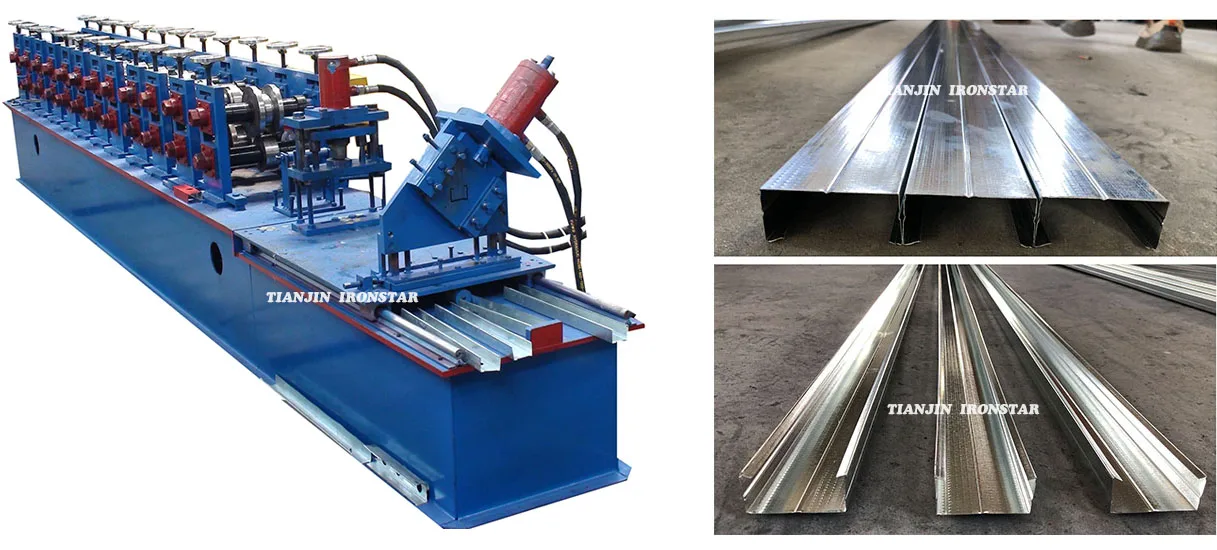

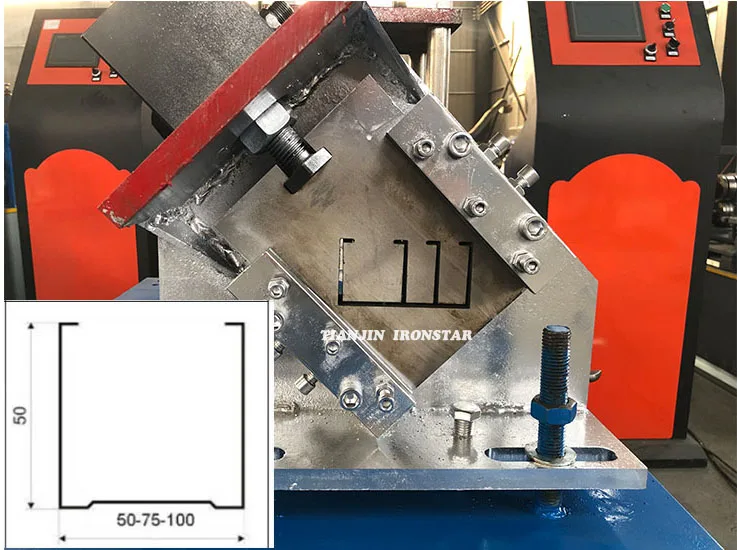

U channel roll forming machine | gypsum u channel making machine | U stud roll forming machine

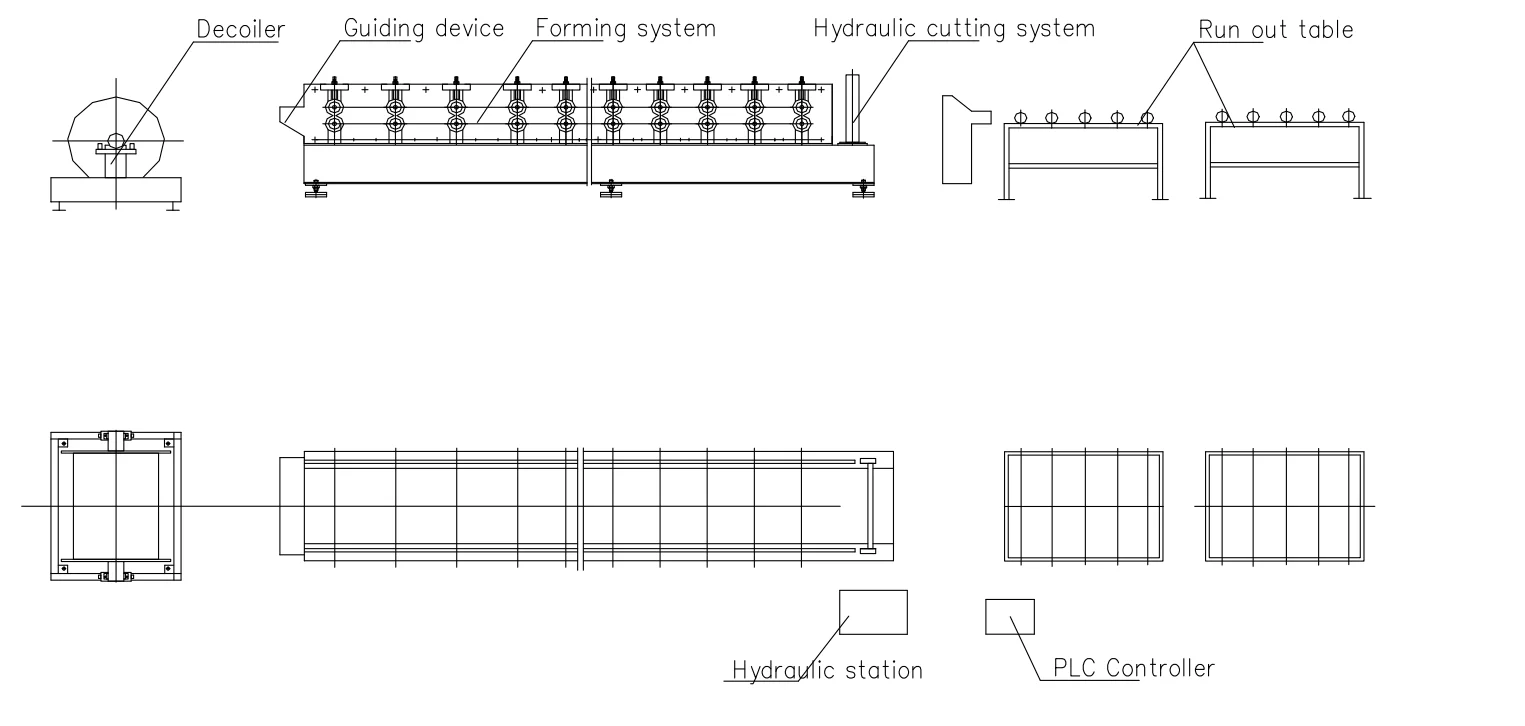

Working flow

Decoiler-roll forming machine-PLC control box-hydraulic cutter-Run out table

| Part details | Item Name | Specification |

| Material | Raw material | Galvanized steel |

| Thickness | 0.3-0.8 mm | |

| Machine | Roller station | 10 |

| Shaft diameter | 55 mm | |

| Shaft material | 45# steel with 0.05mm chrome | |

| Roller material hardness 30-40 HRC | Cr 12 | |

| Machine size | About 4.5×0.8×1 m | |

| Machine weight | About 1.5 ton | |

| Machine color | As customer' request | |

| Working speed | 30-50 m/min | |

| Cutter | Hardness | 50-65 HRC |

| Cutting tolerance | ± 1 mm | |

| Material | Cr 12 | |

| Operate | Hydraulic cutting | |

| Power | Driving way | Chain 1 inch |

| Main power | 4 kw | |

| Pump power | 3 kw | |

| Voltage | 380v/50HZ,3P or customize as customer' request |

|

| Control system | PLC brand | Delta made in Twaiwan |

| Screen | Touchable screen | |

| Language | Chinese and English or add language as customer need | |

| Decoiler | Operation | Manual |

| Weight capicatity | 3 ton | |

| Price | Free as gift | |

| Receiving table | Operation | Manual |

| Length | 3 m | |

| Price | Free as gift |

Details Images

If u want to see the machine working video, please contact with Selena with any way below

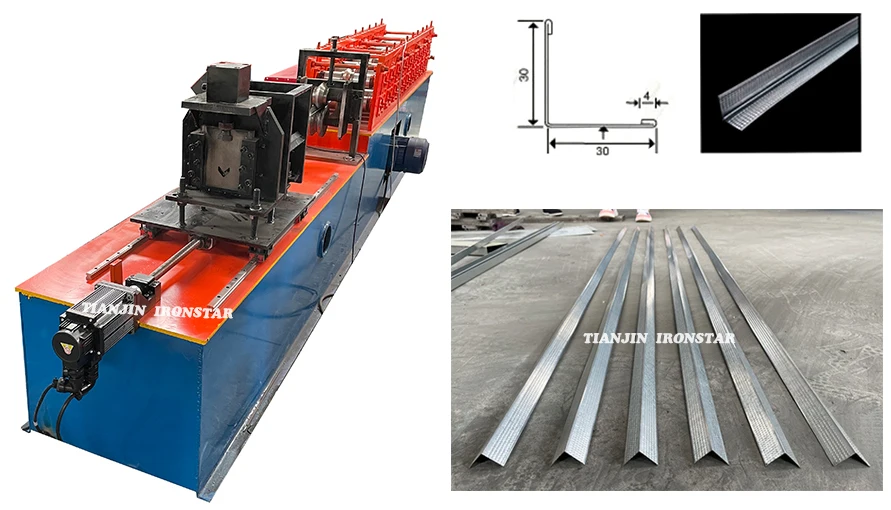

1. Angle bead roll forming machine

Angle bead roll forming machine | Corner bead production line | Metal angle bead machine | Corner bead roll forming machine | V shape roll forming machine | Steel wall angle bar roll forming machine

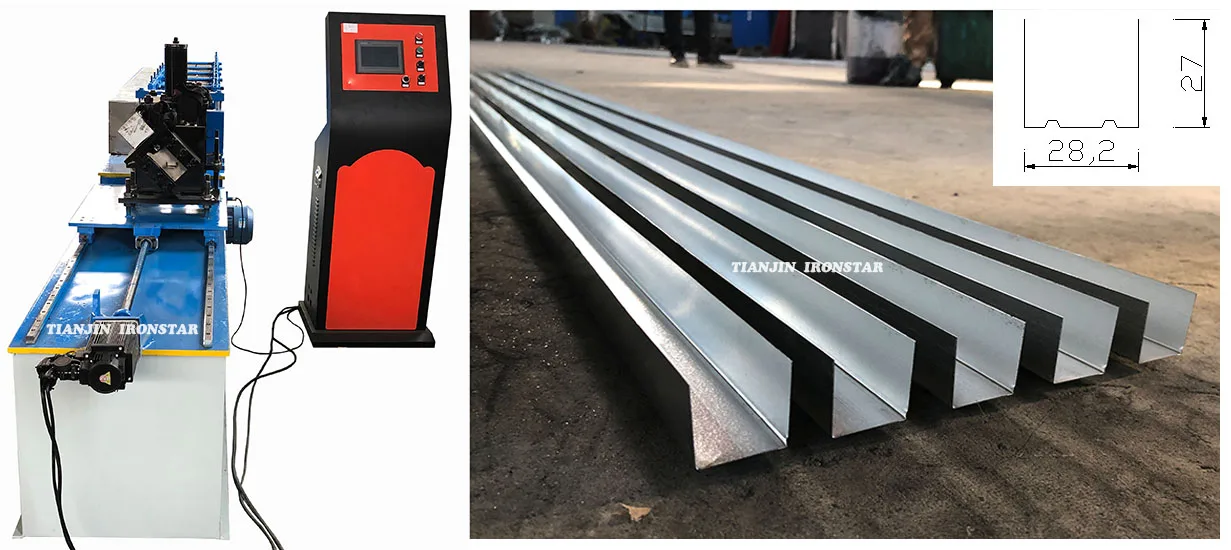

Omega profile roll forming machine | Omega channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine

Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type:

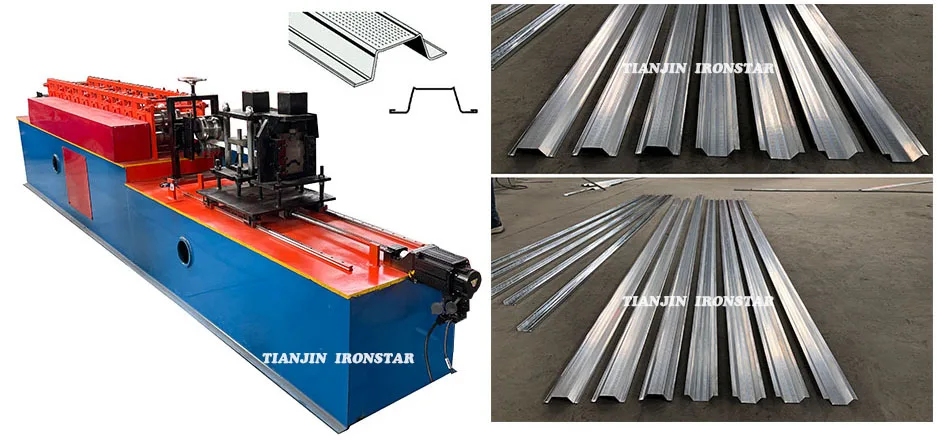

3. C channel roll forming machine

C stud roll forming machine | Cd roll forming machine | C channel roll forming machine

3 in 1 c channel machine | multiple c channel machine | C u channel roll forming machine

U stud roll forming machine | ud roll forming machine | u channel making machine

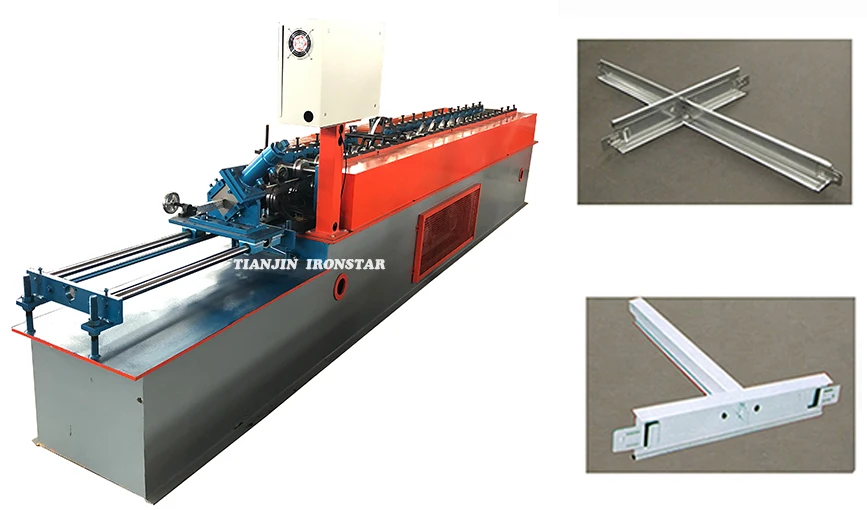

Spring T grid machine |T bar rolling machine | Main T machine | Cross T ceiling keel machine

T grid roll forming machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 8-15 m/min, with servo motor speed can max reach to 10-30 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc, machine details is like up type:

1. Q: How to visit our company:

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station(1hour), then we can pick up you to factory(40min).

A:Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 24 months, all technical staff are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 24 months, if the broken parts can't repair, we will send new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.