UPVC Door Profile Lock Hole Drilling Machine Processing Machine

Other recommendations for your business

Contact us

Quik Detail

| Brand Name | Care |

|---|---|

| Voltage | 380V |

| Weight | 150KG |

| Warranty | 1 Year |

| Production Capacity | 100% |

| Power | 1.65kw |

| Dimension(L*W*H) | 900x1000x1300mm |

| Applicable Material | PVC, UPVC, Aluminum |

| After-sales Service Provided | Online support, Video technical support, Engineers available to service machinery overseas |

| Certification | ce |

| Product name | UPVC Door Profile Lock Hole Drilling Machine Processing Machine |

| Application | Drill PVC lock hole |

| Machine Type | PVC Window Processing Machine |

| Service | Engineers Overseas |

| Power supply | 380V 50Hz |

| Input Power | 1.65kw |

Product Detail

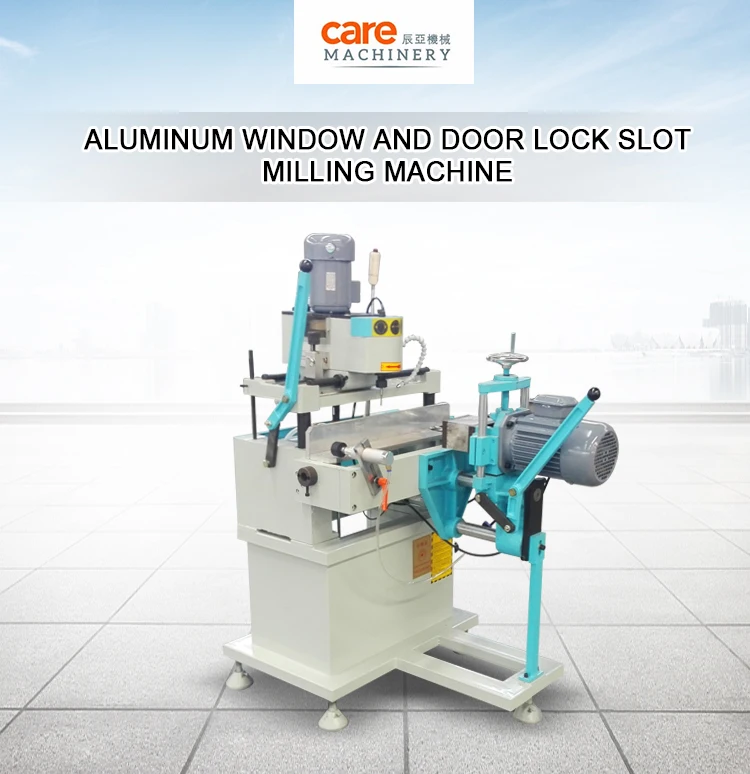

UPVC Door Profile Lock Hole Drilling Machine Processing Machine

Used for copyroutering processing various holes, grooves and water slots on aluminium windows and doors. High precision copy routing, easy operation,two hand operation. Changeable template for different copy routing.

Power | 1.85kw |

Voltage | 380V/50HZ |

Air pressure | 0.6-0.8MPa |

Rotation rate | 12000r/min |

Profile size | 120x100mm(WxH) |

Milling range | 100x300mm |

1. The lock hole drill system opposite the operator, easy operation.

2. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.

3.Auto milling handle hole, Euro groove slot and various hole or slot milling for processing the PVC window profile.

4. Horizontal triple drill and vertical copy router with special cutout working table to realize one time finishing.

5.Large useful scope, high efficiency and convenient operation achieve the contious processing and safe operation

6.Simple model adjustment and replacement, wide adaptation,high efficiency.

We are quality conscious company, and it’s just our origin to supply customers qualified machines. We are always trying to be the “Solution Expert of Glass Processing Facilities”. We not only supply complete glass processing facilities, but our professional engineer team also provide right facility configuration, accordingly customers’ various production requirements and estimated investment. And we’ll provide essential industrial design and technical guidance as well.