Ultra Fine Sponge Iron Dolomite Glass Stone Powder Raymond Grinding Machine Plant

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC |

| Type | Raymond Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1-35t/h |

| Place of Origin | Shanghai |

| Brand Name | Clirik |

| Dimension(L*W*H) | according to models |

| Weight | 1500 KG |

| Warranty | 1 Year |

| Model | CLRM |

| Input Size | 0-35 mm |

| Output Size | 80-500 Mesh |

| Capacity | 1-35 T/H |

| Speed | 85-145 r/min |

| Control System | PLC |

| Motor Brand | Siemens |

| Color | Customized |

| Factory Visit | Welcomed Warmly |

| Market | Global |

| Applicable Industries | Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

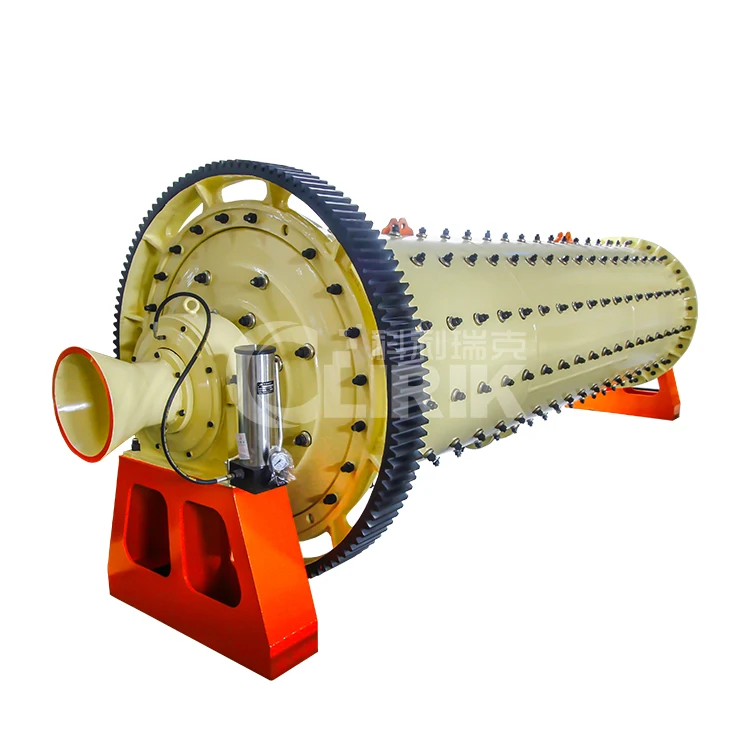

TUltra Fine Sponge Iron Dolomite Glass Stone Powder Raymond Grinding Machine Plant

*every production line needed machines has difference*

*the final quotation will according to your project case*

CLRM Enhanced Roller Grinding Mill Introduction

Clirik enhanced roller grinding mill is suitable for processing various non flammable and non- explosive mineral materials withMoh's hardness less than 6 and humidity less than 6%, it is widely used in the fields of metallurgy, construction, chemical industry,mining, highway construction etc,. The granularity of the finished powder size can be adjusted between 50 and 325 meshes(315- 45 micron). Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic,iron ore, carborundum, bauxite, rock phosphate, coal and other materials, total about 400 kinds of materials.

Parameter of CLRM Enhanced Roller Grinding Mill

|

Model

|

Roller |

Ring |

Main Shaft Speed(r/min)

|

Feeding Size/mm

|

Mesh

|

Motor/kw

|

Capacity/(t/h)

|

||

|

Qty/pcs |

Size/mm |

External Dia/mm |

H/mm |

||||||

|

CLRM9720 |

3-4 |

320*200 |

1077 |

200 |

145 |

<20 |

80-500 |

45*15*37 |

1-7 |

|

CLRM1280 |

3 |

370*240 |

1280 |

240 |

125 |

<20 |

80-400 |

75*15*55 |

2-12 |

|

CLRM1300 |

4 |

410*280 |

1390 |

280 |

112 |

<20 |

80-400 |

110*22*90 |

3-15 |

|

CLRM1620 |

4 |

450*300 |

1620 |

300 |

102 |

<20 |

80-400 |

160*30*132 |

5-20 |

|

CLRM1700A |

4 |

510*300 |

1700 |

300 |

102 |

<30 |

80-325 |

185*37*160 |

6-25 |

|

CLRM1720 |

4 |

510*300 |

1850 |

300 |

92 |

<35 |

80-325 |

250*45*185 |

6-25 |

|

CLRM1900A |

4 |

600*300 |

1900 |

300 |

92 |

<35 |

80-325 |

250*45*220 |

8-32 |

|

CLRM2150 |

4 |

600*300 |

2150 |

300 |

85 |

<35 |

80-325 |

315*45*280 |

12-35 |

Note: for the motor data in the above sheet such as “45*15*37” means the main motor “classifier motor” blower motor.

CLRM Enhanced Roller Grinding Mill Working Place

CLRM Enhanced Roller Grinding Mill Production Line

The standard configuration of the CLRM enhanced roller grinding mill consists of main unit, reducer, powder classifier, cyclone powdercollector, dustcleaner, blower, electrical cabinet and pipes. The optional accessories include crusher, bucket elevator, feeder.

CLRM Enhanced Roller Grinding Mill Working Principle

Big materials are crushed by jaw crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, andare fed evenly and continuously by vibrating feeder into the main unit for gninding. The grinded powder are carried by the airflowfrom the blower to the cassifier to be lassified, the particles which meet the fineness enter cyclone collector through pipe, andare separated and collected there. They are discharged at the discharging valve to become finished products; the airflow is suckedto the blower by return pipe on the top of cyclone collector. The whole airflow system is a sealed circulation, and is circulated underpositive and negative air pressure.

CLRM Enhanced Roller Grinding Mill Advantages

Optimized grinding part, increase grinding efiency

Compared with the previous mill the grind pressure increased 10%, grinding area up 15 -20%. Optimized the roller layout,escalated the ficient grinding space.

Triple vibrating damping for working stability

Triple damping to resist the vibrating transmit in the main unit base, volute aiflow house, unit body, grinding part. Be sure thestable grinding condition.

New type impeller of cassifier with VFD

Equipped the new cage type impeller for lassifier, adjust the speed freely by VFD, enlarge the output size range to 80-500 mesh.

Grinding device adopts superimposed multistage seal, prolong the lubricating cycle.

Shanghai Clirik Machinery Co. Ltd., located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

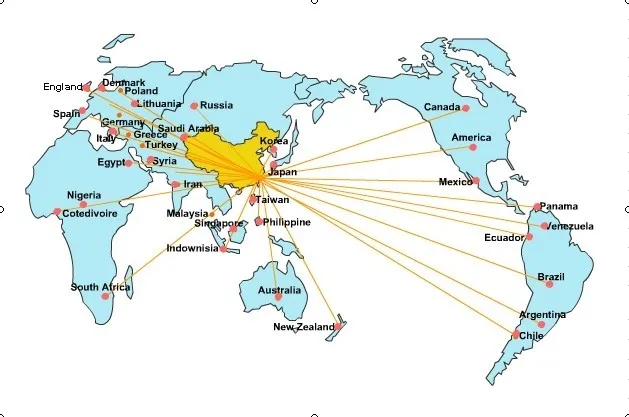

So far, we have established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, European version coarse grinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

Clirik Honor

Clirik Office

Clirik Work Shop

Clirik Sales Team

Clirik Exhibition Attend

Clirik Customer Visit

Clirik Customer Site

knowledge and full global service capability to ensure the best results for our customer's business.

Pre-sale services

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments;

> Select equipment model;

> Sdeign and manufacture products according to clients' special requirement;

> Train technical personnel for clients.

Services during the sale

Respect clients; devote ourselves to improving the total value of clients.

> Pre-check and accept products ahead of delivery;

> help clients to draft solution.

After-sales service

Provide considerate services to minimize clients' worries.

> Assist clients to prepare for the first construction scheme;

> Install and debug the equipment;

> Train the first-line operators on site;

> Examine the equipment regularly;

> Take initiative to eliminate the troubles rapidly at site;

> Distribute the guarantee fittings door-to-door;

> Provide technical exchanging;

> Provide maintenance for big items

1. who are we?

Shanghai Clirik based in Shanghai, China, start from 2010,sell to Mid East(30.00%),Africa(20.00%),Southeast Asia(19.00%),South Asia(15.00%),North America(3.00%),South America(3.00%),Domestic Market(3.00%),Southern Europe(2.00%),Eastern Europe(00.00%),Eastern Asia(00.00%),Western Europe(00.00%),Central America(00.00%),Northern Europe(00.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Grinding Mill, Crusher and other stone powder production needed machines

4. why should you buy from us not from other suppliers?

>>> CE, ISO9001

>>> factory sell directly

>>> 30 years experience, professional

>>> Sales market all over the world

>>> good after sales serive

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CPT,DDU,Express Delivery;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese,French

Shanghai Clirik Machinery

↓↓↓ you are welcome to leave us your inquiry here, so you will get quotation very soon ↓↓↓