Woodworking Cutting Saw Machine Altendorf Sliding Table Panel Saw Machinery

US $3,220.00-3,420.00 / set

1 set(s)Minimum order

Type:

Panel Saw

use:

Woodworking

Style:

Horizontal

place of origin:

Shandong, China

brand name:

hairui keyuan machinery

voltage:

380V/220/50HZ

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Panel Saw |

|---|---|

| use | Woodworking |

| Style | Horizontal |

| place of origin | Shandong, China |

| brand name | hairui keyuan machinery |

| voltage | 380V/220/50HZ |

| dimension(l*w*h) | 3.2x1.1x1m |

| warranty | 1 Year |

| weight (kg) | 800 KG |

| power (kw) | 6.6 |

| Key Selling Points | High-accuracy |

| max.cutting height at 90°(mm) | 110mm |

| max.cutting height at 45°(mm) | 75mm |

| max. length of workpiece (mm) | 3000mm |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor |

| Name | Precision Panel Saw |

| Application | Furniture Maker, Factory manufacturing |

| Max. Length of Workpiece (mm) | 3000MM |

| Sliding Table Size | 3200x390mm |

| Saw Blade Diameter | 300MM |

| Scoring Saw Blade Diameter | 120MM |

| Main Motor | 5.5KW |

| Auxiliary saw motor | 1.1KW |

| Main saw speed | 4000/6000rpm |

| Auxiliary saw speed | 7000/8000rpm |

| Condition | New |

| Warranty of core components | 1 Year |

| Use | Woodworking |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Retail, Construction works , Advertising Company, Other |

| Marketing Type | New Product 2022 |

Product Detail

Products Description

Applicable products:

MDF, particleboard, wood-based panels, ABS panels, PVC panels, plexiglass, solid wood and other wood structure and hardness similar to the plate.

Working principle:

hand move the mobile workbench before and after the move to achieve the sawing process, scribe saw sawing in advance, the main saw blade can be used to carry out variable speed sawing.

Achieved effect:

manual and easy to feed when the labor-saving, high precision, access to good quality sawing.

Structure advantages:

mobile workbench guide rail with high strength extruded aluminum alloy, high strength, nondeformation, chrome rod structure, high positioning accuracy, table surface oxidation treatment, beautiful wear-resistant.

Control panel, easy to operate, zero-based operation.

3.2 meters double layer double bond thickening push platform, chrome plated round rod guide rail, with step by step locking device, push and pull smooth, high precision, durable without deformation

Double saw blade structure , clear division of labor , smallsaw marking , large sawing to prevent board burr and edgecollapse.

Cast iron structure,easy to cut without sliding,using non-

rust chrome plated mold shaft to promote smooth.

1.90m retractable sliding tablewith ruler processing plane and high positioning accuracy of hollow baffle.

Adopt national standard pure copper motor, main motor power 5.5KW small motor power 1.1KW, powerful cutting, durable. The motor shell uses the new aluminum shell, fast heat dissipation, small resonance, low noise.

The machine is a double auxiliary table, cast iron material, are widened and thickened processing, compared with the traditional auxiliary table longer service life.

The machine is equipped with a movable oil filling device, which is mainly used to lubricate the internal oil circuit and protect the internal parts.

Product Paramenters

name | MS6132S | Net weight | 800kg |

Sliding table size | 3200*390mm | Saw blade tilt | 90°-- 45° |

Maximum cutting width | 1250mm | Main motor | 5.5KW |

Main saw blade diameter | 300mm | Main saw speed | 4000/6000rpm |

Diameter of secondary saw blade | 120mm | Auxiliary saw motor | 1.1KW |

Main saw cutting height | 110mm | Auxiliary saw speed | 7000/8000rpm |

Spindle diameter | 30mm | Auxiliarysaw spindle | 20mm |

Sample & Application

Related Product

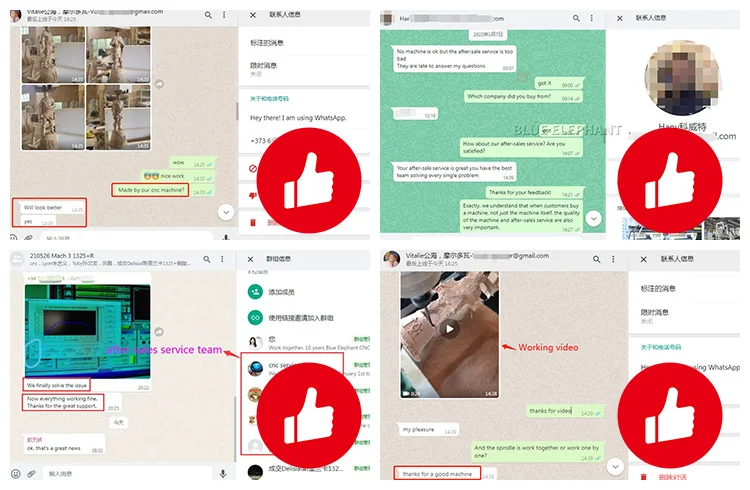

Customer feedback

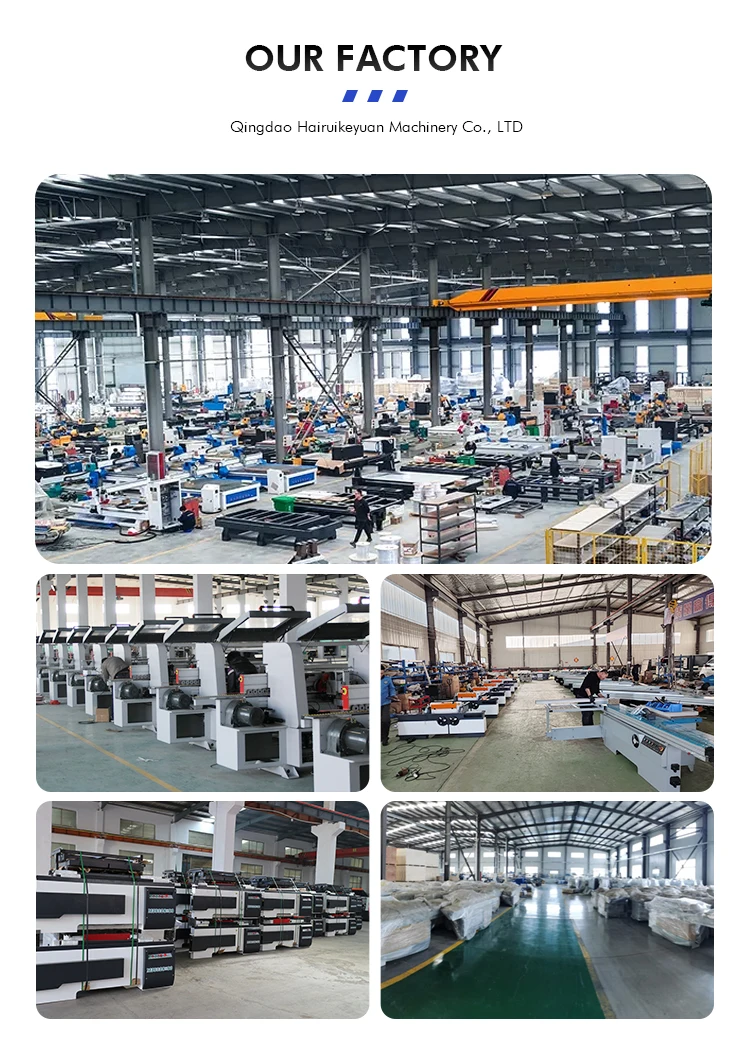

Company Profile

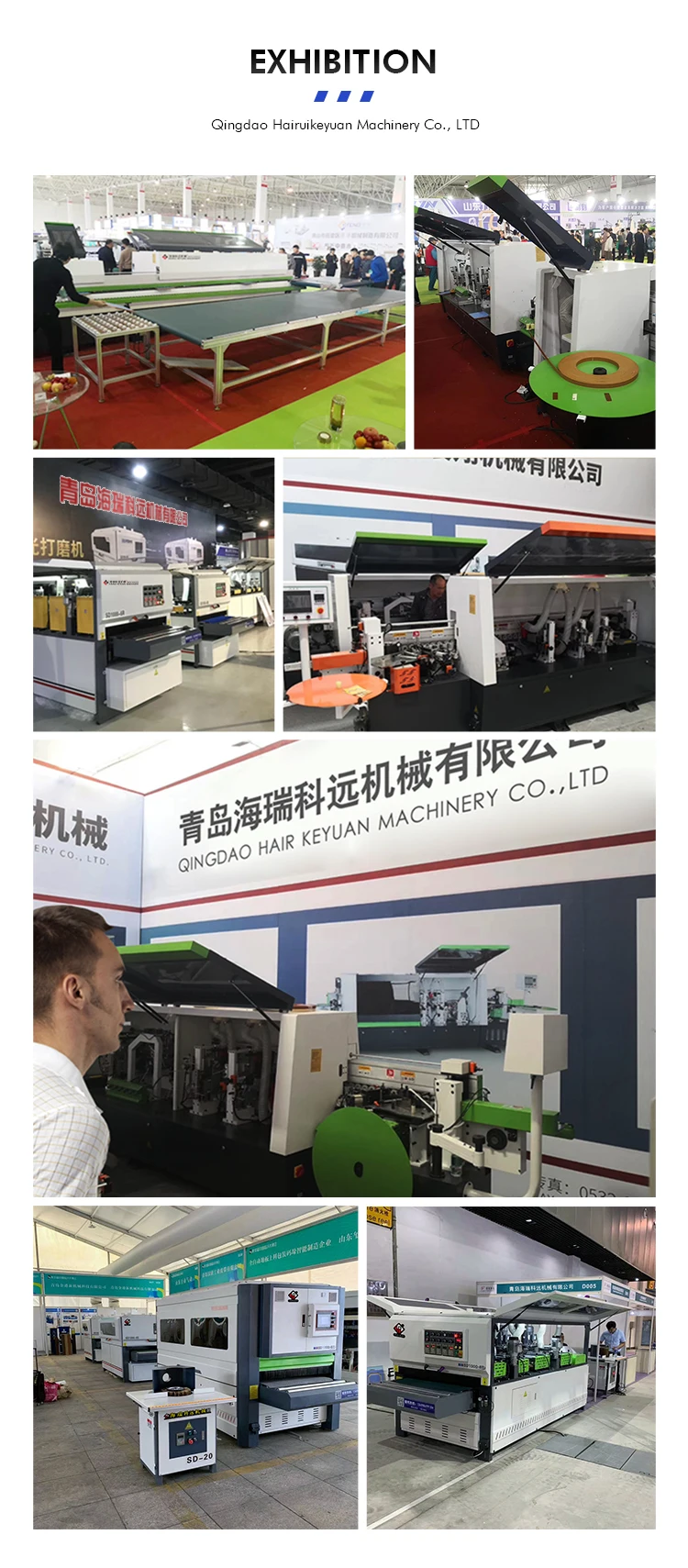

Exhibition

FAQ

Q: Do you offer installation?

A: Our machines are almost assembled before loading in container. It is very easy for installation in your workshop. Video guidance and English manual can be provided freely.

Q: Where can we get replacement parts?

A: Most of the spare parts are ready in stock. They will be sent to the buyer directly from our warehouse with original prices.

Q: How long can we get replacement parts?

A: Common spare parts can be delivered by express with in one week. Some parts can be purchased locally.

Q: What technical support do you offer?

A:1. Technical support by phone, email or WhatsApp/Skype around the clock.

2. Friendly English version manual and operation video.

Q: What other machine do you offer?

Q: What other machine do you offer?

A: We provide one-stop shop service of woodworking machines for the buyers. Other kinds of woodworking machines, like sandingmachine, CNC router, drilling machine, saw machine can be provided as well.

Q: Can you set the system to our language?

A: Our system supports common languages like Chinese, English, Russian, Spanish, French, Germany.