1st. Overview

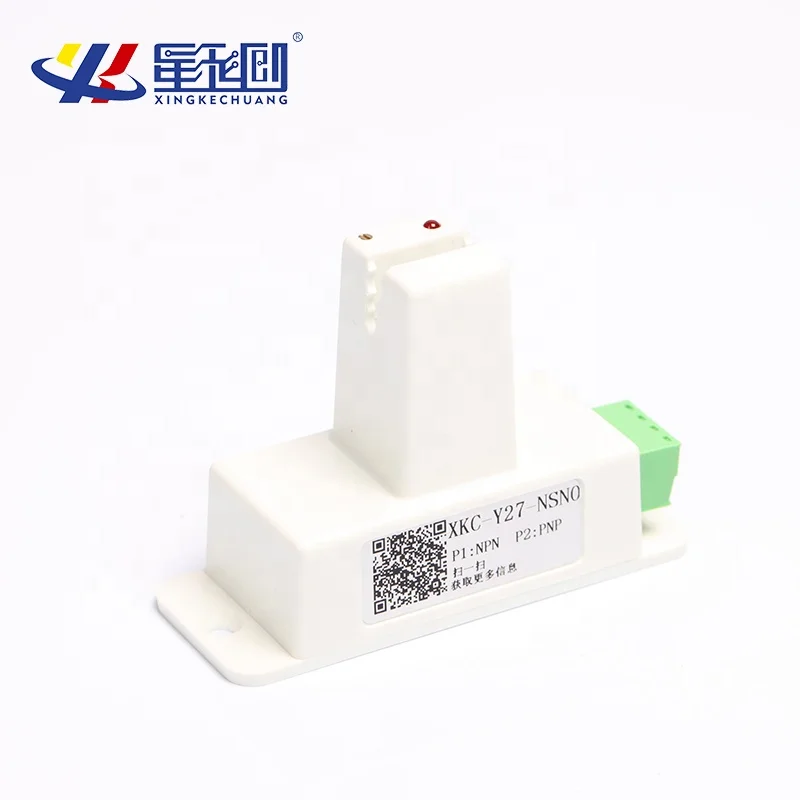

The intelligent non-contact small tube liquid level sensor (hereinafter referred to as the small tube sensor) adopts

advanced signal processing technology and high-speed signal processing chip, specifically for liquid level detection needs

such as infusion tubes and industrial small tubes. Intelligent non-contact small tube liquid level sensor can output NPN

and PNP signals at the same time, which can meet the needs of various occasions.

2nd.Product Features

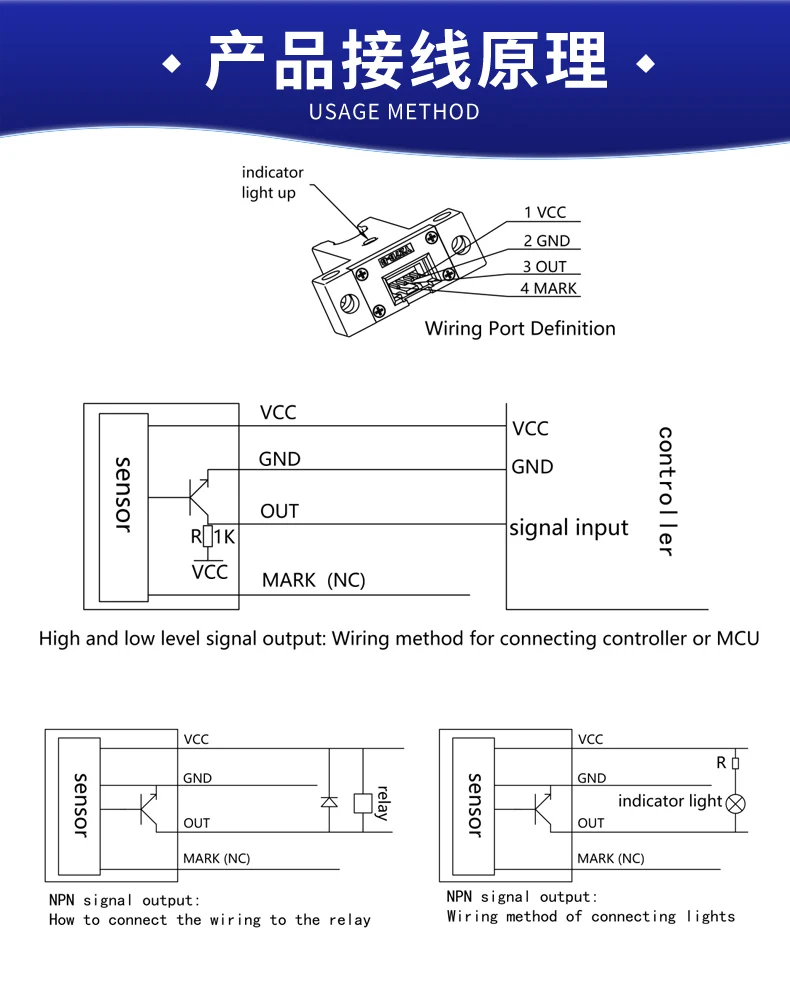

1. The non-contact small tube liquid level sensor is suitable for the outer wall of the non-metallic small tube without

direct contact with the liquid. It will not be corroded by strong acids and alkalis and other corrosive liquids, and will not

be affected by scale or other debris.

2. Intelligent liquid level reference adjustment and liquid level memory function, liquid level status display mode, can

realize multi-point series connection; support NPN and PNP simultaneous output (define drive load such as relay, buzzer,

solenoid valve, indicator Lights and other loads).

3. Pure electronic circuit structure, non-mechanical working mode, stable performance and durability.

4. High stability, high sensitivity, strong anti-interference ability, free from external electromagnetic interference, special

treatment for power frequency interference and common mode interference, to be compatible with most of the 24V power

adapters on the market.

5. Strong compatibility, penetrating a variety of non-metallic infusion tubes, plastic, glass, ceramic and other small tubes.

The diameter of the tube is 3mm~5mm, which can meet most of the thin tubes.

6. NPN and PNP output modes, wide voltage range (2 AAA batteries and external 24V power supply can be used),

suitable for connecting various circuits and product applications.

3rd.Working principle and status description:

(1) Working principle: The intelligent non-contact small-tube liquid level sensor uses the inductive capacitance of water to detect whether there is liquid. When there is no liquid close to the sensor, the distributed capacitance on the sensor causes the sensor to There is a certain static capacitance on the ground, when the liquid level rises slowly, it is close to sensing The parasitic capacitance of the liquid will be coupled to the static capacitance when the sensor is used, and the capacitance value of the sensor will become larger. The changed capacitance signal is then input to the control IC for signal conversion, and the changed capacitance is converted into a certain electrical signal. The amount of change is detected and judged by a certain algorithm. When the amount of change exceeds a certain threshold, it is considered that the liquid level has reached the sensing point.

(2) Description of indicator status:

Battery powered:

Long press the power button to turn on, the indicator light will flash; Long press the power button to shut down, the indicator light will stay on for 1.5 seconds and then go out; When the sensor senses liquid, it will flash every 10 seconds;

When the sensor senses that there is no liquid, it will flash twice every 2 seconds or so;

When the battery power is low, it stops working and enters dormancy, and the indicator light turns on once every 5

seconds.

External power supply:

Long press the power button to turn on, the indicator light will flash;

Long press the power button to shut down, the indicator light will stay on for 1.5 seconds and then go out;

When the sensor senses liquid, the indicator light is always on;

When the sensor senses that there is no liquid, it will flash twice every 2 seconds or so;

(3) Buzzer State Description:

When the external power is turned on, it will automatically turn on and the buzzer will beep once.

Long press the power button to turn it on in the shutdown state, the buzzer will beep once.

In the power-on state, press and hold the power button to power off, and the buzzer will beep for 1.5 seconds.

When the sensor senses liquid, the buzzer does not sound;

When the sensor senses that there is no liquid, it will beep twice every 2 seconds;

(4) Power button Instructions for use

1. Press and hold the power button for 5 seconds in the power-on state, the buzzer will beep for 1.5 seconds, and the

indicator light will be on for 1.5 seconds and then shut down.

2. When the power is off, press and hold the power button for 3 seconds, the buzzer will beep once, and the indicator light will flash once at the same time, and then the machine will start.

3. It will automatically turn on when the external power supply is connected, no need to press the power button. When

using the battery alone, you need to press and hold the power button to turn on the battery after installing the battery