XKC Y28 OEM Factory contactless type liquid level sensor for smart water appliances and home appliance water detect

100 piece(s)Minimum order

Series:

Liquid Level Sensor

Features:

Liquid Level Sensor

Mounting Type:

wall mounted glue fixed

Description:

non-contact liquid water level sensor, tank level sensor liquid

Model Number:

XKC-Y28

Type:

Liquid Level Sensor

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

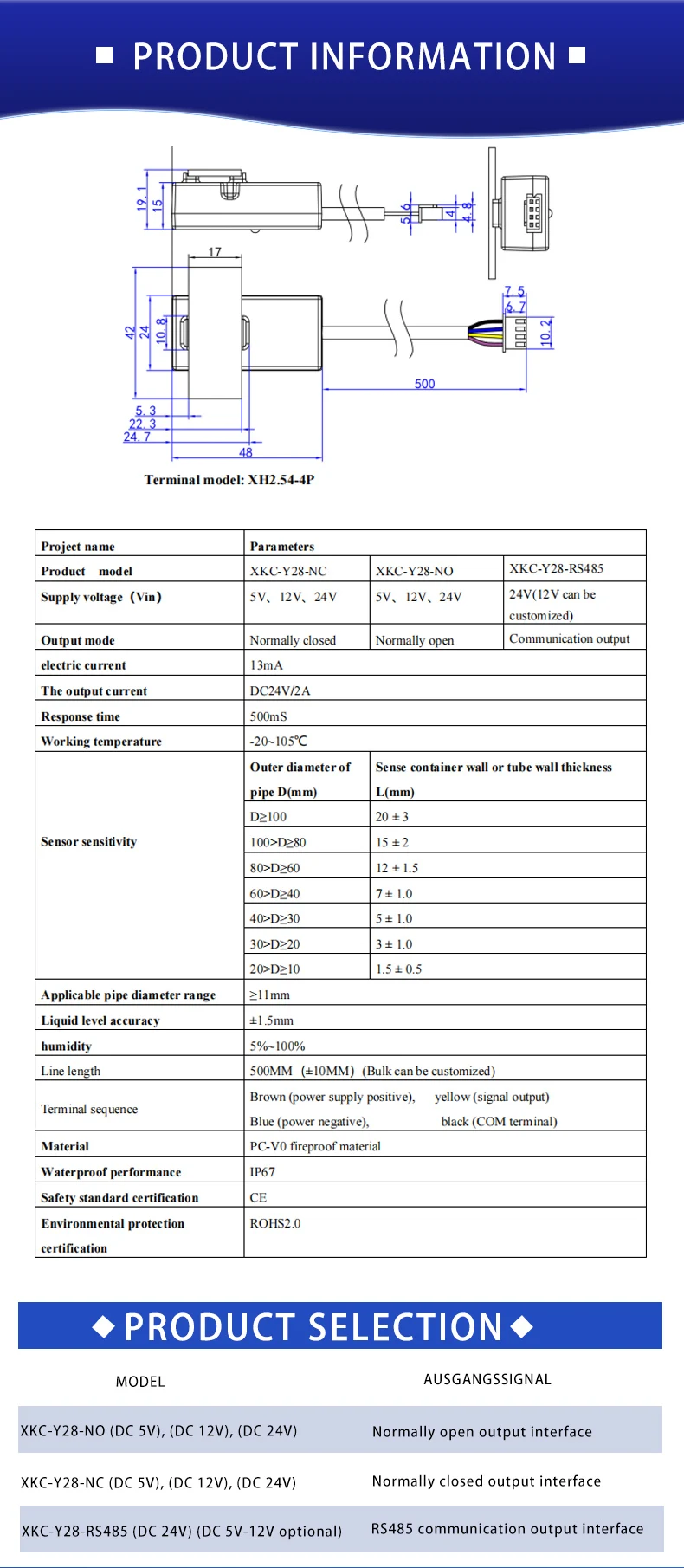

| Series | Liquid Level Sensor |

|---|---|

| Features | Liquid Level Sensor |

| Mounting Type | wall mounted glue fixed |

| Description | non-contact liquid water level sensor, tank level sensor liquid |

| Model Number | XKC-Y28 |

| Type | Liquid Level Sensor |

| Place of Origin | shenzhen |

| Brand Name | XKC |

| Use | Liquid level switch |

| Theory | Liquid level switch |

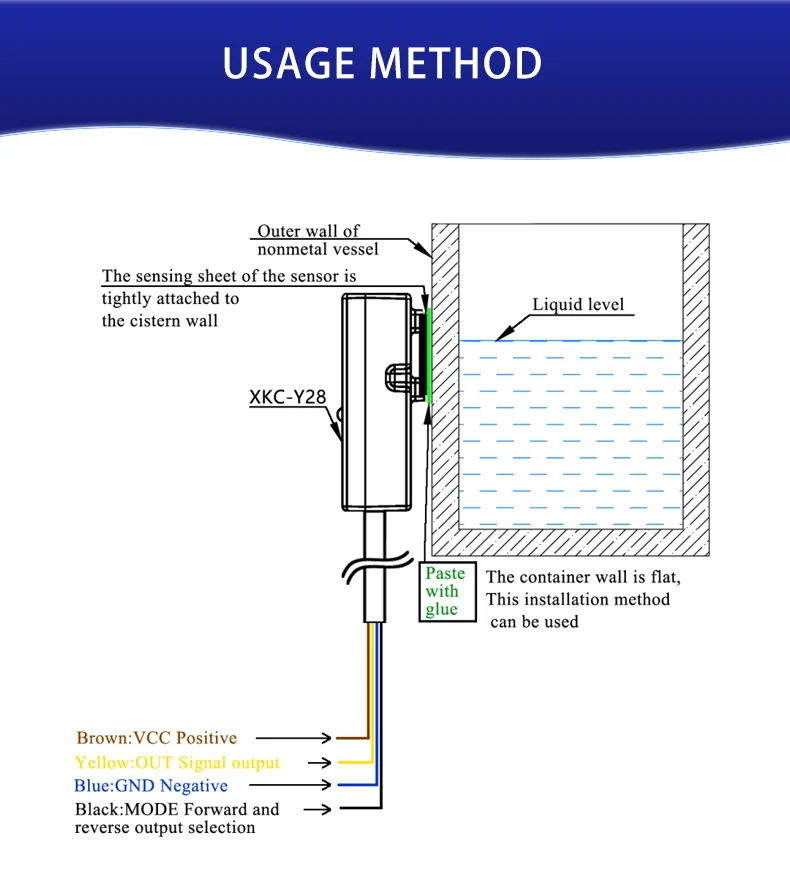

| Output | switch output, V/NPN/PNP |

| Application | Application |

| Detection Type | Detection Type |

| Certificate | CE,RoHS |

| Customized support | OEM/ODM |

| MOQ | 100 Pcs |

| Input Voltage | DC 5-24v |

Product Detail

Product Description

1st. Overview

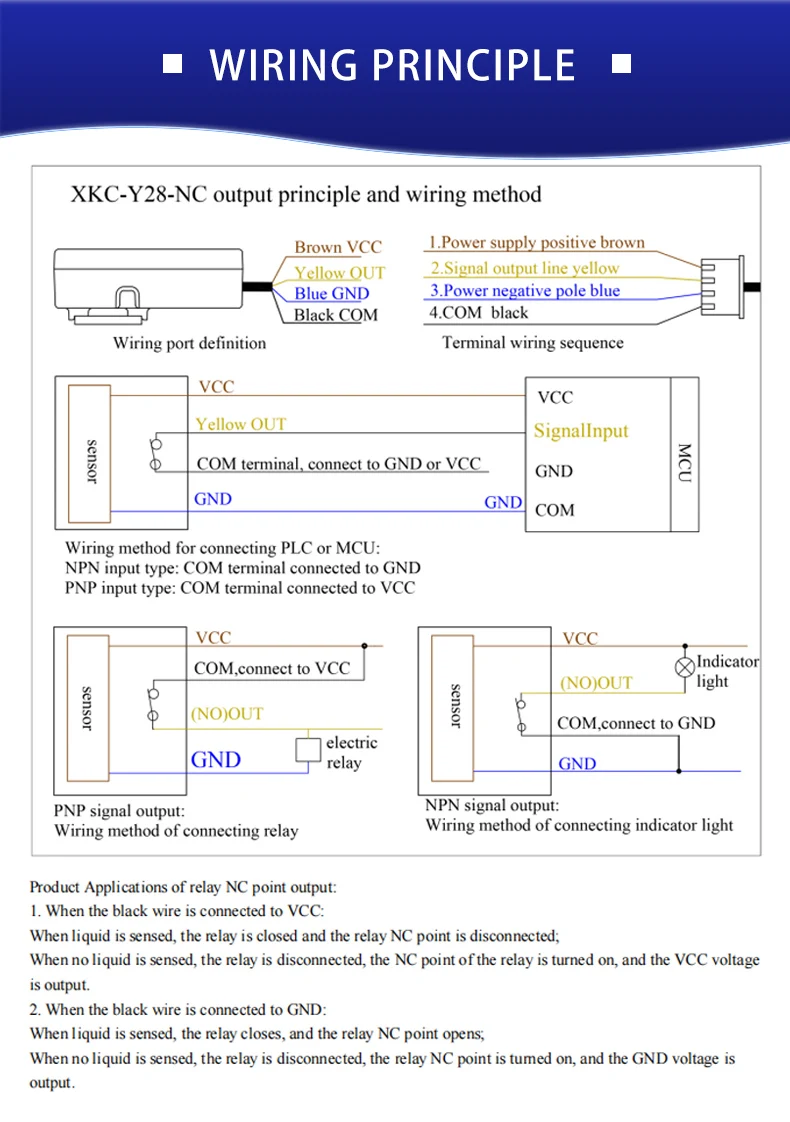

The intelligent non-contact liquid level sensor (hereinafter referred to as the liquid level sensor) adopts advanced signal

processing technology and high-speed signal processing chip, which breaks through the influence of the container wall

thickness and realizes the true non-contact of the liquid level in the closed container. Contact detection. The liquid level

sensor (probe) is installed on the upper and lower sides of the outer wall of the container to be tested (the high and low

levels of the liquid level). The non-metallic container does not need to be opened, and the installation is simple and does

not affect production. It can detect the level of various toxic substances, strong acids, strong alkalis and various liquids in

high-pressure airtight containers. The liquid level sensor has no special requirements for the material of the liquid

medium and container, and can be widely used.

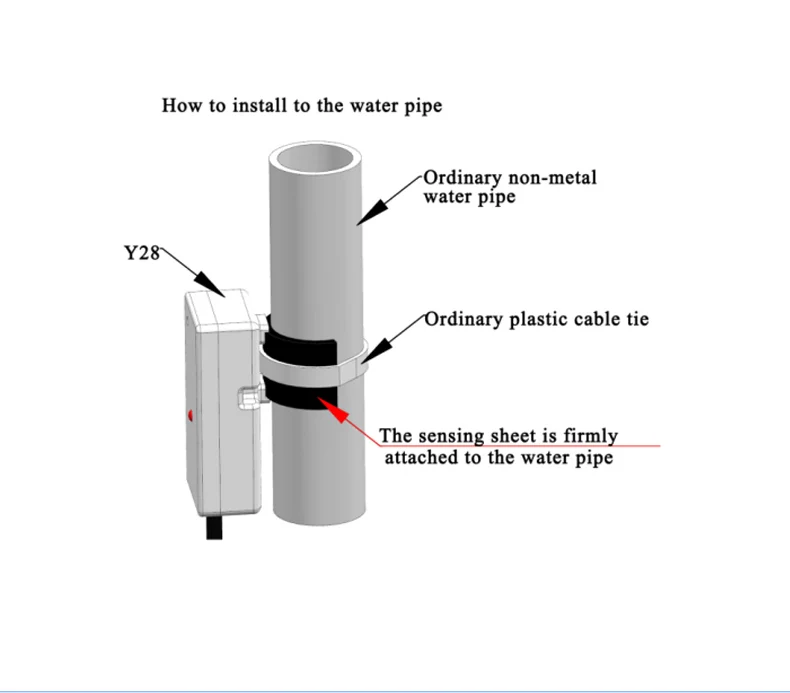

XKC-Y28-NO/NC/ RS485 products are specially developed for non-metallic pipes (pipe outer diameter D≥11MM) or flat

container liquid level detection. They are relay normally open output and relay normally closed outputand RS485

interface output.

2nd.Product Features

1. XCK-Y28-NO/NC/ RS485 sensor, suitable for non-metallic pipes (pipe outer diameter D≥11MM) or flat containers

without direct contact with liquids,

It will not be corroded by strong acids or alkalis and other corrosive liquids, and will not be affected by scale or other

debris. It can be completed to detect whether there is liquid inside the container or pipeline.

2. Intelligent liquid level reference adjustment and liquid level memory function, liquid level status display mode, can

realize multi-point series connection.

3. The detection is accurate and stable, and the boiling water level can be detected.

4. Pure electronic circuit structure, non-mechanical working mode, stable performance and durability.

5. High stability, high sensitivity, strong anti-interference ability, free from external electromagnetic interference, special

treatment for power frequency interference and common mode interference, to be compatible with all 5V, 12V, 24V

power adapters on the market.

6. Strong compatibility, penetrating various non-metallic container pipes, such as plastic, glass, ceramics and other

containers, the induction pipe wall thickness can reach 20mm; suitable for all kinds of curved, arc, cylindrical containers

or pipes Liquid level detection.

7. The voltage can be selected (5V, 12V, 24V), suitable for connecting various circuits and product applications.

3rd.Product Applications

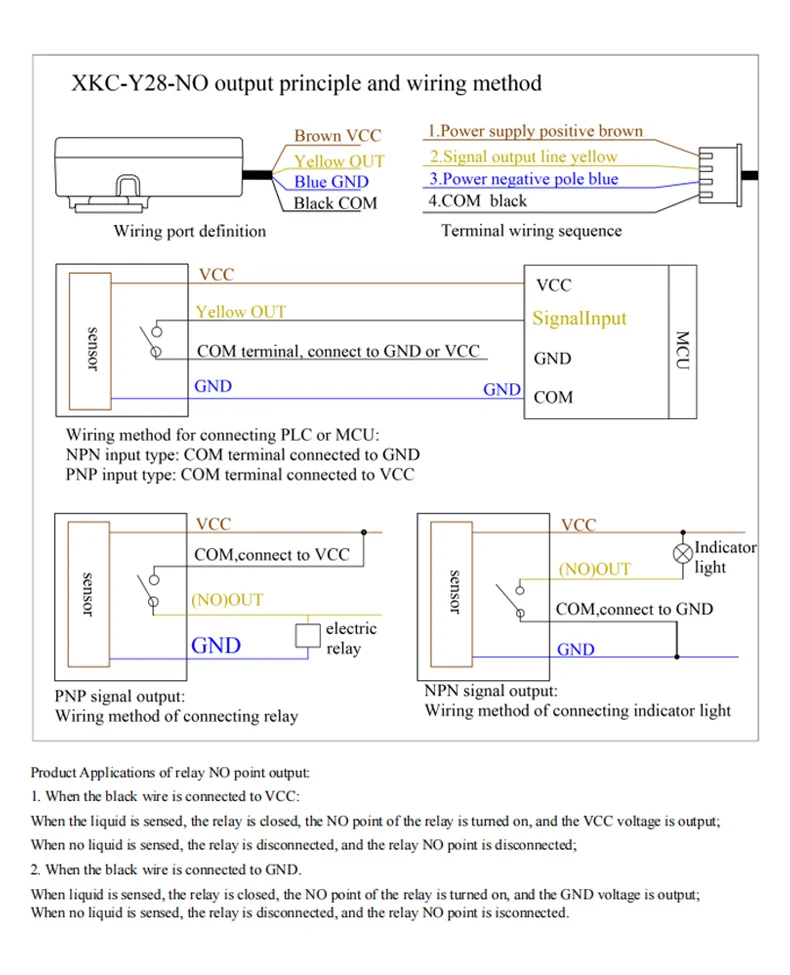

The intelligent non-contact liquid level sensor uses the inductive capacitance of water to detect whether there is liquid.

When there is no liquid close to the sensor, the sensor has a certain static capacitance to the ground due to the distributed

capacitance on the sensor. When the liquid level slowly rises and approaches the sensor, the parasitic capacitance of the

liquid will be coupled to this static capacitance, making the capacitance value of the sensor larger, and the changed

capacitance signal is then input to the control IC for signal conversion. The capacitance is converted into a change of a

certain electrical signal, and then a certain algorithm is used to detect and judge the degree of this change. When the

change exceeds a certain threshold, it is considered that the liquid level has reached the sensing point..