Xunke 10% Discount Tube and Sheet Fiber Laser Cutting Machine with Customized Configuration

Other recommendations for your business

Contact us

Quik Detail

| Applicable Material | metal |

|---|---|

| condition | New |

| laser type | Fiber Laser |

| cutting area | 1500mm*3000mm |

| cutting speed | 0-40000mm/min |

| graphic format supported | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

| cutting thickness | Depends |

| cnc or not | Yes |

| cooling mode | WATER COOLING |

| place of origin | Shandong, China |

| brand name | xunke |

| Laser Source Brand | RAYCUS |

| laser head brand | Raytools |

| servo motor brand | FUJI |

| guiderail brand | HIWIN |

| control system brand | Cypcut |

| weight (kg) | 8000 KG |

| Key Selling Points | Multifunctional |

| optical lens brand | II-VI |

| warranty | 3 years |

| mode of operation | continuous wave |

| configuration | 4-axis |

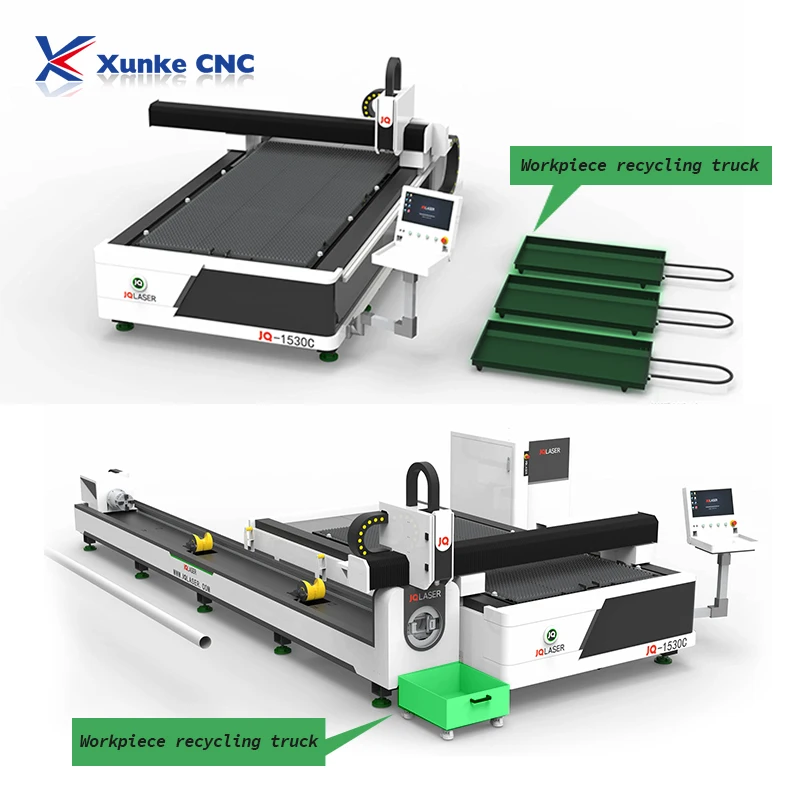

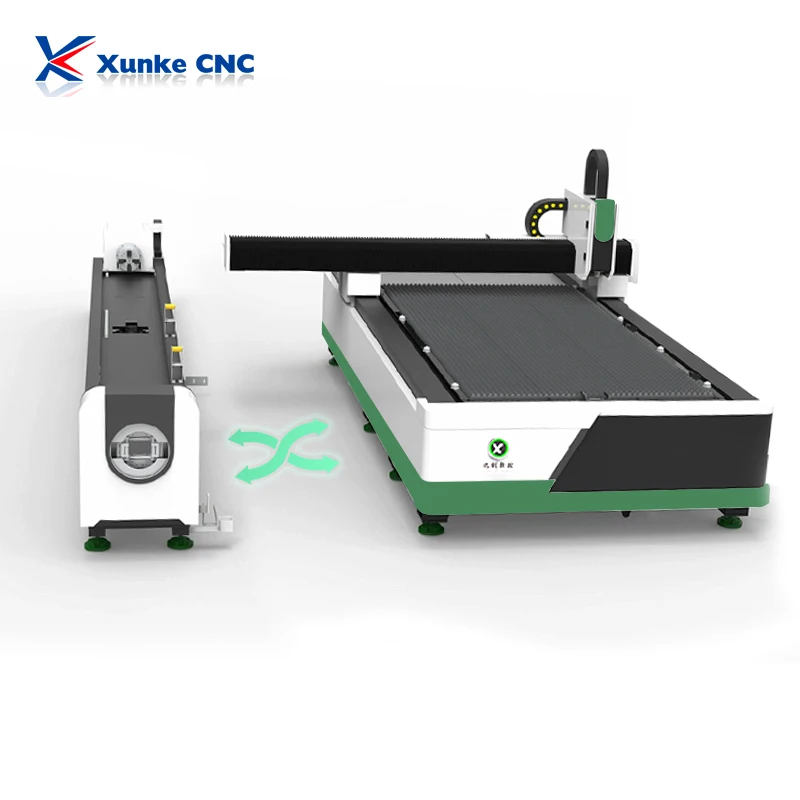

| products handled | Sheet Metal and Tube |

| feature | Water-cooled |

| Control Software | CYPCUT |

| Product name | Fiber Laser Metal Cutting Machine |

| Keyword | Laser Metal Cutting Cnc Machine |

| Application | Metal Steel Carbon Copper, LASER CUTTING |

| Control system | Cypcut System |

| Power supply | 380V/50HZ/60HZ |

| Cooling system | Water Cooling System |

| Positioning Accuracy | 0.03mm |

| Max cutting speed | 700mm/min |

| Working area | 1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm |

| Laser Cutting Head | RAYTOOLS/AU3TECH/WSX/PRECITEC |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 3 years |

| Core Components | motor, Bearing, Engine |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, co2 laser cutting machine |

Product Detail

1 | Model | XK-3015ST |

2 | Plane cutting width (length X width) | 3000mmx1500mm |

3 | Pipe cutting specifications | Φ20-φ220,L=6000mm |

4 | X-axis travel | 2350 mm |

5 | Y-axis stroke | 3050 mm |

6 | Z axis travel | 240 mm |

7 | X, Y axis positioning accuracy | ±0.05/1000mm mm |

8 | X, Y axis repeat positioning accuracy | ±0.03/1000mm mm |

9 | Acceleration | 1G m/s² |

10 | Maximum operating speed | 100 m/min |

11 | Maximum platform load | 900 kg |

12 | Host appearance (length, width and height) | 7900×3960×1650 mm |

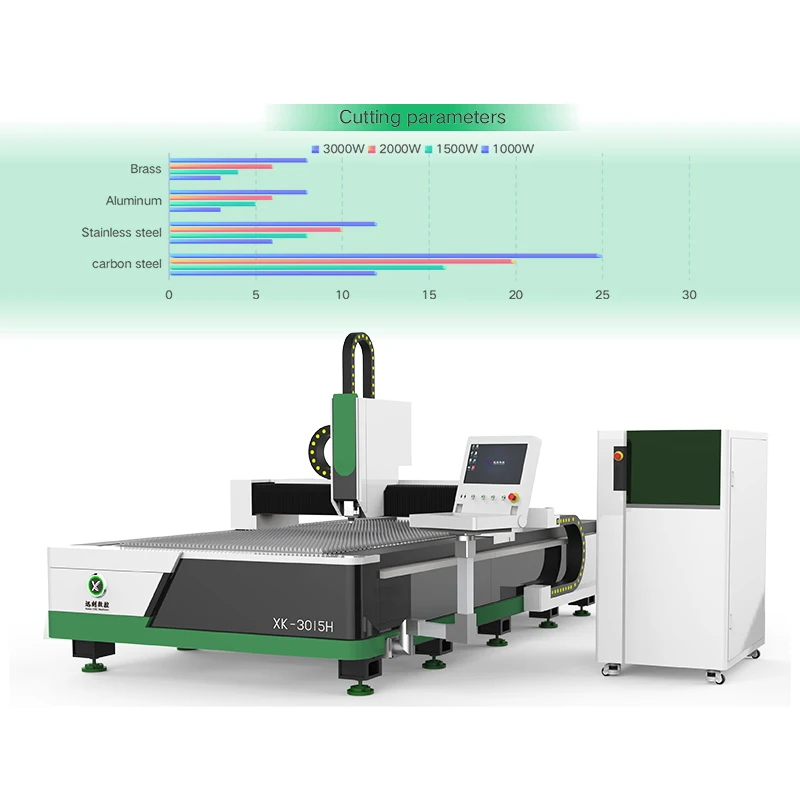

13 | Laser power | 1000-3000 w |

14 | Control | system |

15 | Power supply requirement | 380v/50Hz |

The bed is placed in the natural environment for aging treatment for 3 months to remove the internal stress of the bed to ensure that the equipment will not be deformed for long-term use and ensure accuracy.

precision ≤ 0.05mm. Fully upgraded dust-proof design,double-layer protection

A: Since the market is large, we have some stocks in factory, so if you need standard machines, we can ship the machine within 5 days, or you have special needs, we will ship the equipment to you from 10 to 20 days.

2. Q: Can you make customized machine model?

A: Sure. We are manufacturers not trading company, we have our own R&D department, and cnc machine processing center for machine body making. We have some successful cases like machine with up-down table and special holding device. As long as you have specific requirements, we will definitely not let you down!

3. Q: I am the new comer, if I buy machine from you, will I get any help or support?

A: If you buy machines from us, we will sent manual and technical videos for you to know more about the machine firstly, after receiving the machine, we will provide one to one technical support online. Providing the best service is our aim.

4. Q: What’s the policy for the damaged parts?

A: We have one year warranty, if the parts break within the warranty, we will send replacement for free, but you need to take charge of the freight.

A: If any problems occur, please contact us as soon as possible instead of solving it by yourselves or other engineers.