ABC 3-layer Blown Film Extrusion Line Three Layer Co-Extrusion Film Blowing Extruder Machine Blow Moulding Machine

US $38,000.00-76,000.00 / set

1 set(s)Minimum order

plastic processed:

HDPE, LDPE, Lldpe

output (kg/h):

20 - 80

screw diameter (mm):

50

weight (kg):

3500

number of layers:

Three-layer

brand name:

LIFENG

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | HDPE, LDPE, Lldpe |

|---|---|

| output (kg/h) | 20 - 80 |

| screw diameter (mm) | 50 |

| weight (kg) | 3500 |

| number of layers | Three-layer |

| brand name | LIFENG |

| place of origin | Zhejiang, China |

| die size(mm) | 60 - 80 mm |

| model number | 1600 |

| voltage | 380v 50hz |

| dimension(l*w*h) | 5300*3800*4800 |

| key selling points | Easy to Operate |

| warranty | 1 Year |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| Product name | ABC film blowing machine |

| Material | HDPE LDPE LLDPE 100%Biodegradable |

| Film type | ABC Three Layers Hdpe |

| Film Thickness (mm) | 0.06-0.15 |

| Screw L/D Ratio | 30:1 HDPE ABA FILM BLOWING MACHINE |

| Air Ring | Double Lip Air Ring |

| Application | Film |

| Condition | New |

| Applicable Industries | Manufacturing Plant |

| Showroom Location | None |

| Warranty of core components | 1 Year |

| Year | 2024 |

Product Detail

Title goes here.

Dear Customer:

How are you?

Zhejiang Lifeng Machinery Co., Ltd,which has a long history, grand scale, self-research, sales service is professionally manufacturing plastic soft packaging machine with high technology.The quality of its products had firstly passed the certification of quality management system ISO9001-2008 and CE certification of European Union.

We are professional manufacture in kinds of Bag Making Machine,Film Blowing Machine,Printing Machine,Cutting Machine ,Recycle Machine,Plastic Air Bubble Film Machine,Laminating Machine,Slitting and Rewinding Machine are popular in all the markets of the whole world ,products are exported to eastern Europe,North America ,Southeast,Asia,Russia,Africa,Middle East and more than 20 countries and regions , They win good reaction in the market and welcomed by vast customers no matter new or old from home and abroad.

If you are interested in some items,please feel free to contact me

Look forward your reply

Best regards

Jeanne

Product Paramenters

ABC 3 Layers Co-extrusionFilm Blowing Machine

Machine Introduction:

The machine plasticizes and extrudes three kinds of same or different raw materials into the co extrusion compound die head through two screws to produce compound film, which greatly improves the physical properties and strength of the film. The film has good barrier and air tightness.

The machine adopts advanced continuous head, the product is smooth and uniform, which ensures the quality requirements of the follow-up process equipment such as printing machine and bag making machine. It is suitable for the production of composite pearlescent film, composite liquid packaging film, insulating film, multi-functional agricultural film, etc.

Parts name | Technical Parameter | |

The Main Parameters | ||

Suitable Material | HDPE,LDPE,LLDPE,MLLDPE | |

Output | 50-260KG/H | |

Max Film | 1600MM | |

Film Thickness | 0.03-0.2MM | |

Working voltage | 380V,50HZ,3PHASE | |

mainframe | Two Layer Stairs | |

Total Power | About 220KW | |

Machine size | About 10.0 * 6.5 * 12 m | |

Machine weight | About 15Ton | |

Extruder | ||

Harden Gear box | LYZD-200 Harden gear box x3 | |

Screw and barrel | SJ—75X1、70X2 Sacm-645/38Cr moala Processing technology: change screw to HDPE/Recycle film special screw Keywords quenching and tempering, nitriding treatment; spraying alloy; Nitriding depth: > 0.6 mm, nitriding hardness ≥ 960; The feed section is longitudinally slotted to increase the extrusion amount. Meanwhile, the plasticizing time of raw materials in the barrel is long and the plasticizing effect is better. Low speed can reduce the wear of barrel and screw and prolong the service life | |

Screw ratio | 30 : 1 | |

Screw rotation | 0~120 | |

Cooling blower | 3 Phase blower 370W 5 pcs | |

Heating rings+ | Stainless steel heating rings | |

Details Images

SJ—75X1、70X2 Sacm-645/38Cr moala

If you want to know more information ,please feel free to contact Jeanne

Here is Jeanne business card

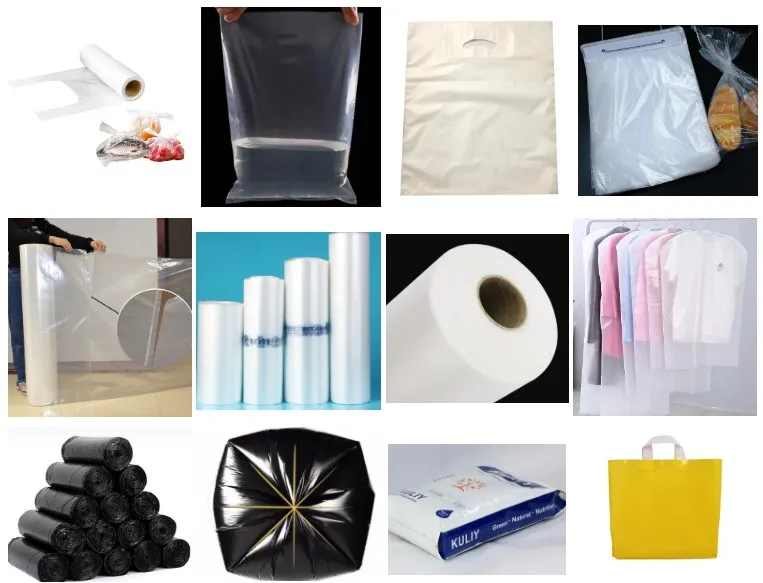

Bag styles which can produced by our factory

About Us

Dear Sir

Good day

We are a Chinese machine factory ,our produce machine as below

1.Mixer

suitable for plastics mixing and blending, as blending for new material, regrind or powder, and they also can be used for mixing of unproportional new material and regrind.

2.Film blowing machine

we have single screw model ,AB,ABA,ABC ,Experimental machines and so on. producing plastic roll

3.Printing machine,flexo printing machine and gravure printing machine

printing logo ,picture or words on the film

4.Slitting machine

cutting all kinds of material from big to small

5.Bag making machine,all kinds of plastic bag styles

cutting and sealing plastic roll to finish bag

6.waste plastic recycling machine

collecting waste plastic ,process,particles

If you have any inquiry in above machine ,please feel free to contact me

I will do my best to provide best service

Look forward your reply

Best regards

Jeanne

Company Profile

FAQ

Q1:Are you a factory or trading company?

A1: We are established in 1995, a actual factory and manufacturer in the line of printing&package machine for 20 years.

Q2:Where is your factory located? How can I visit there?

A2: Our factory is located in Rui'an City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: Which industries are widely used in of your machine?

A3: Those are mainly used in making plastic bags and labels in the maket. Examples of stand up pouch, zipper pouch, plastic bag for daily necessities and food, plastic label for drink bottle, Foil yogurt cup, Medical pouch, laminated film or soft car board,etc.

Q4: How about the payment term?

A4: For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.

Q5: What about your main market?

A5: Ourproducts be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6: Quality is the most important principle. GREAT WALL people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

Q7:What about warranty and do the engineers available to overseas?

A7: One year warranty. During this period, if the machine has some problems, our engineers can go abroad to fix for you.

Q8:What about the service after sale?

A8: One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12 hours and help you to slove the problem.

A1: We are established in 1995, a actual factory and manufacturer in the line of printing&package machine for 20 years.

Q2:Where is your factory located? How can I visit there?

A2: Our factory is located in Rui'an City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us!

Q3: Which industries are widely used in of your machine?

A3: Those are mainly used in making plastic bags and labels in the maket. Examples of stand up pouch, zipper pouch, plastic bag for daily necessities and food, plastic label for drink bottle, Foil yogurt cup, Medical pouch, laminated film or soft car board,etc.

Q4: How about the payment term?

A4: For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.

Q5: What about your main market?

A5: Ourproducts be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6: Quality is the most important principle. GREAT WALL people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

Q7:What about warranty and do the engineers available to overseas?

A7: One year warranty. During this period, if the machine has some problems, our engineers can go abroad to fix for you.

Q8:What about the service after sale?

A8: One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12 hours and help you to slove the problem.