Air Blower Centrifugal Fan for Tunnel Kiln

US $1,900.00-4,282.00 / set

1 set(s)Minimum order

customized support:

OEM

Electric Current Type:

AC

Blade Material:

Cast Iron

mounting:

Duct Fan

place of origin:

Henan, China

brand name:

Yuanhang

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| customized support | OEM |

|---|---|

| Electric Current Type | AC |

| Blade Material | Cast Iron |

| mounting | Duct Fan |

| place of origin | Henan, China |

| brand name | Yuanhang |

| Voltage | 220V |

| warranty | 5 years |

| After-sales Service Provided | Video technical support, tunnel kiln for bricks |

| Raw material | Blower |

| Block Type | Centrifugal Blower |

| Product Name | Industrial Air Blowers |

| Name | tunnel kiln |

| Keywords | Centrifugal Fans |

| Products | tunnel brick kiln |

| Model | kiln for bricks |

| Color | clay bricks kiln |

| Brick type | clay brick tunnel kiln |

| Type | Centrifugal Fan |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining |

Product Detail

Automatic Brick making machine Wheel kiln High tension Air blower Brick Tunnel kiln equipment Accessories

What is Clay Brick Modular Tunnel Kiln?

1. Tunnel Kiln Brick Plant is the most popular, fully automatic modern brick plant.

2. It consists of aging warehouse ( for processed raw materials maturing ) brick production line, dryer kiln and fired kiln.

3. High Capacity. Daily output ranges from 80,000 to 300,000 pcs Chinese standard bricks (240*115*53 mm)

4. Required land (>=1.5 acres)

5. Be adaptable to both solid and hollow bricks

6. Output is not subject to weather, continuous running. (You can operate 365 days per year)

7. Heavy investment, quick investment return

1. Tunnel Kiln Brick Plant is the most popular, fully automatic modern brick plant.

2. It consists of aging warehouse ( for processed raw materials maturing ) brick production line, dryer kiln and fired kiln.

3. High Capacity. Daily output ranges from 80,000 to 300,000 pcs Chinese standard bricks (240*115*53 mm)

4. Required land (>=1.5 acres)

5. Be adaptable to both solid and hollow bricks

6. Output is not subject to weather, continuous running. (You can operate 365 days per year)

7. Heavy investment, quick investment return

Products Description

Flow chart

Features of Our Yuanhang Tunnel Kiln

1. Adopt "quick sintering" theory, It takes about 44 hours from wet bricks drying to final bricks. Waste hot air from firing kiln is recycled to heat wet bricks in dryer kiln. making full use of fuel. Energy saving.

2. Equipped with advanced wastes gas disposal system, achieve environmental protection standard.

3. Customize different size tunnel kiln based on your expected output.

4. Engineers are available to provide on-site service.

5. Worry-free service. Our service including

1》Free site choosing consultation

2》Free raw materials analysis

3》Layout plan

4》Supply full line brick prodcution machinery, materials needed for tunnel kiln construction and equipment in tunnel kiln

on-site engineers service

5》Machinery installation, test-run to qualified bricks

6》Provide entire working life after sales service and spare parts

1. Adopt "quick sintering" theory, It takes about 44 hours from wet bricks drying to final bricks. Waste hot air from firing kiln is recycled to heat wet bricks in dryer kiln. making full use of fuel. Energy saving.

2. Equipped with advanced wastes gas disposal system, achieve environmental protection standard.

3. Customize different size tunnel kiln based on your expected output.

4. Engineers are available to provide on-site service.

5. Worry-free service. Our service including

1》Free site choosing consultation

2》Free raw materials analysis

3》Layout plan

4》Supply full line brick prodcution machinery, materials needed for tunnel kiln construction and equipment in tunnel kiln

on-site engineers service

5》Machinery installation, test-run to qualified bricks

6》Provide entire working life after sales service and spare parts

We select the most suitable product model for you according to customer requirements, provide delivery pictures and videos, and provide customers with installation, commissioning and technical training services. Let customers rest assured to use. | ||||||||

FAQ

Q1: What is the warranty for this machine?

A1: 3 years excluding the easy wear parts.Spare parts is recommended to keep at least one year in case of emergency

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

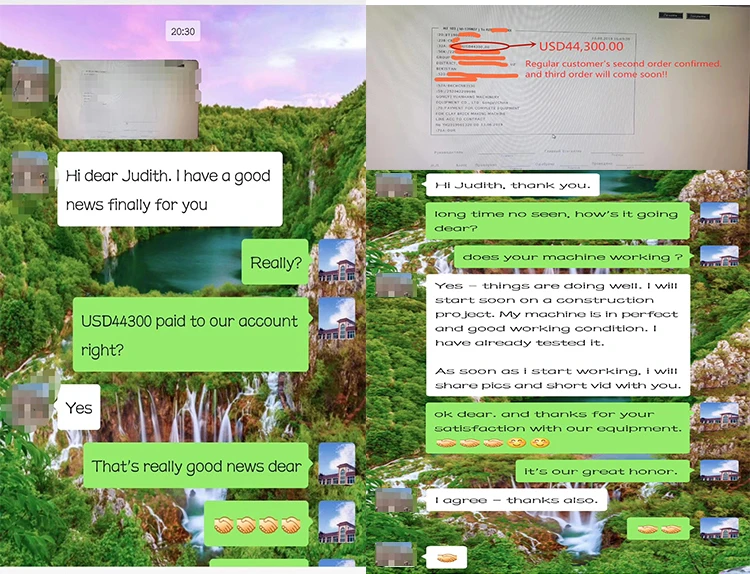

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

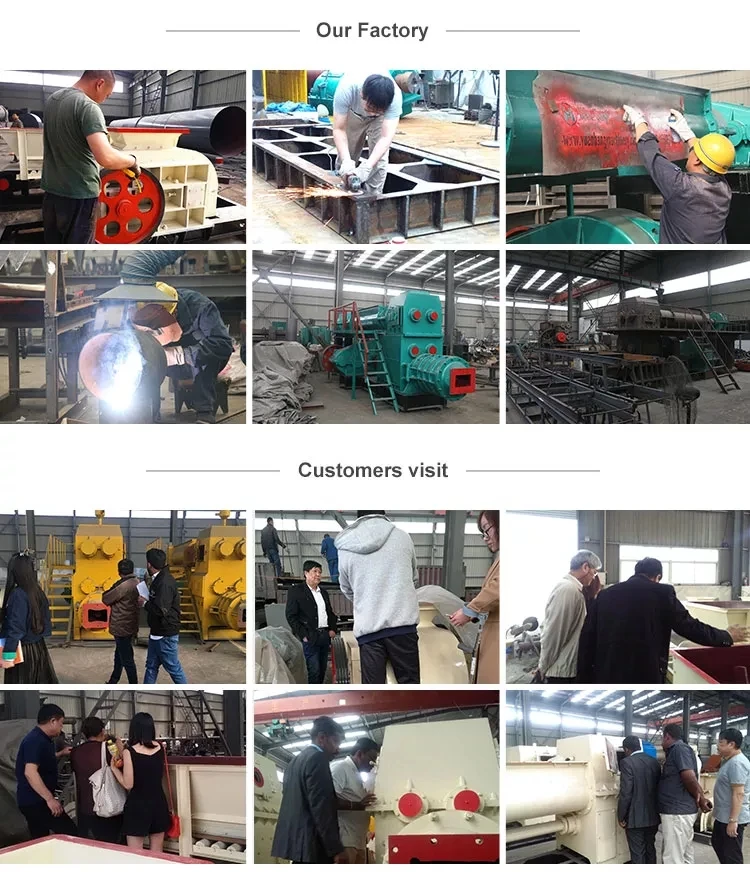

Company Profile

Yuanhang Group Machinery World Quality

Yuanhang Group Machinery Equipment Co.,Ltd is the high-tech enterprise, integrating R&D, manufacture and trade as one body forclay brick making production line machinery and hoffman kiln and tunnel kiln construction .

Our equipment is superior handling , advanced technology and reliable quality . We provide raw material analysis, site planning,kiln construction , equipment installation and trial running services. We have a professional technicians and engineers teams tosupport your project . After years of hard exploration, we have established a set of complete and effective service system forbefore sales , medium sales and after sales .

Our products exported 28 countries and regions , like Indonesia, Myanmar, Kazakhstan, Uzbekistan, Russia, Nepal, Sudan, SouthAfrica, Uganda , Peru , Chile , etc . Our products enjoy a great reputation during the customers and have been sold all over theworld .

Welcome you to visit us ! Let’s walk hand in hand , and win the world together !

Our Service

Pre-Sales Service

* Device model choice.

* Design and manufacture products according to the special requirements of customers.

* Train technicians for customers.

* Send engineers and technicians to the customers to plan the site and design the best process and plan free of charge.

After-Sales Service

* Create a customer profile and track it

* Detailed registration and storage of the daily information and processing of the hotline.

* Notify the equipment customers who have passed the warranty period and regularly inform the equipment maintenance details

* Conduct statistical analysis on product quality and service issues to improve quality services.