Aiwei One Key Start Easy Operate Manufacturer's Bricks Machinery QT4-25 Automatic Block Making Machine with Low Price for Sale

Other recommendations for your business

Contact us

Quik Detail

| Type | Hollow Block Making Machine, Paving Block Making Machine, Curbstone Block Machine, Interlock Block Making Machine |

|---|---|

| Brick Raw Material | CONCRETE |

| Processing | Brick Production Line |

| Method | Hydraulic pressure and Vibration molding |

| Automatic | Yes |

| Place of Origin | Shandong, China |

| Brand Name | Aiwei |

| Voltage | 380V/220V/415V(Adjustable) |

| Dimension(L*W*H) | 2150*1660*2550mm |

| Warranty | 2 years |

| Key Selling Points | Long Service Life |

| Brick size | 400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other |

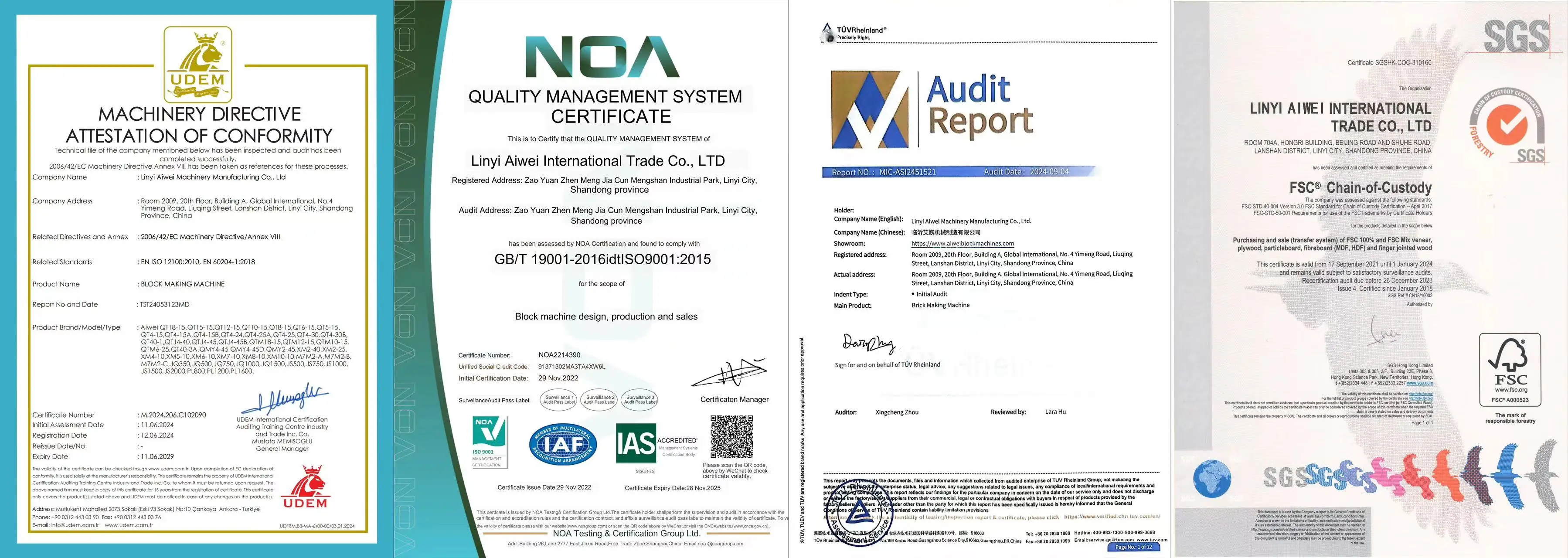

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | PLC, Engine, Gear, motor |

| Weight (KG) | 2000 kg |

| Name | QT4-25 Automatic Block Making Machine |

| Raw material | Fly Ash,Cement,Sand,Concrete,Cinder,Crushed Stone,Slag,Dust |

| After-sales Service Provided | Provided |

| Condition | New |

| Brick type | Hollow+Solid+Interlocking+Paver+Curbstone |

| Pallet size | 960*700*25-30mm |

| Advantage | Operating Easily,High Efficiency,High Capacity |

| Color | Customer's Demand |

| Application | Building Material Shops,Manufacturing Plant,Farms,Retail |

| Feature | High Profit and High Capacity |

Product Detail

2. Good adaptability of raw material, advanced step vibration molding technology to local conditions to take advantage of a variety of waste ash residue and reasonable reduce the amount of cement, produce a variety of high quality load-bearing or non-load-bearing masonry products.

3. Good adaptability, by simple changing the mould, you can quickly adjust products production, the maximum extent to meet the market demand, so that the device maximize performance.

Basic Patameters of QT 4-25 Automatic Block Making Machine | ||||||

Capacity | 400*200*200mm | 4PCS/Mould | 720PCS/Hour | |||

400*150*200mm | 5PCS/Mould | 900PCS/Hour | ||||

400(*100*200mm | 7PCS/Mould | 1008PCS/Hour | ||||

225*112.5*60mm | 12PCS/Mould | 1728PCS/Hour | ||||

Oversize | 2490*16400*2140mm | |||||

Pallet Size | 880/850*550*20mm | |||||

Total Power | 20.6KW | |||||

Volt(adjustable) | 380V/220V/415V,3phases | |||||

Forming cycle | 20-25s | |||||