Automatic 4000-48000BPH Bottling Line for Bottled Water Pure Water Filling Machine

Other recommendations for your business

Contact us

Quik Detail

| application | Food, Beverage, Chemical, water line |

|---|---|

| packaging type | Cartons, CANS, Bottles, Barrel, case |

| packaging material | Plastic, paper, metal, Wood |

| automatic grade | Automatic |

| driven type | Electric |

| Voltage | 380/220V 50HZ |

| place of origin | Shanghai, China |

| brand name | LILAN |

| dimension(l*w*h) | customized |

| warranty | 1 Year |

| key selling points | Automatic |

| filling material | Beer, Milk, Water, Oil, Juice, Other |

| filling accuracy | 0.1 |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, PLC, Gear, Bearing, Gearbox, Other |

| After-sales Service Provided | Video technical support, Field installation, commissioning and training, Online support, Field maintenance and repair service |

| Power | 100kw |

| Product name | Complete water bottle line |

| Production speed | 6000-36000BPH |

| Packing method | PET bottle |

| Usage | Plastic bottle,PET bottle |

| Color | Standard color |

| Electric component | Siemens,Danfoss,Schneider,FESTO,SICK |

| Motor | SEW or EVENGEAR |

| Training support | Yes |

| Type | Filling Machine, |

| Weight | 10000 KG |

Product Detail

NOTE: The specific mode of transportation, freight and delivery time shall be subject to negotiation and communication between the parties .

Automatic 4000-48000BPH bottling line for bottled water pure water filling machine

Water Lines

Success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety and cost optimisation. Whether you’re producing still or sparkling water, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

With over decade years of experience in designing and implementing customised complete PET line solutions for water; our technician team can help you reach your production targets.

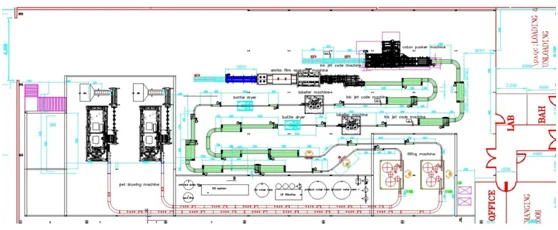

Bottle water line is combined by several unit machines, each unit machine cooperates with other machines together to achieve the best production efficiency, save cost and time. The complete water bottle production line capacity can be 6000BPH-48000BPH (based on 500ml), the speed and the water factory specification is customized according to your technical requirements.

Automatic bottle water production line is composed of:

1. bottle blow molding machine

2. air conveyor, 3 in 1 filling machine, (or combiblock machine)

3. bottle conveyor and light checking

4. bottle dryer and date coding machine

5. labeling machine (sleeve labeling machine, hot melt glue labeling machine, self-adhesive labeling machine, cold glue labeling machine)

6. packing machine (shrink film wrapping packing machine, wraparound case packing machine, pick and place type case packer)

7. carton/ pack conveyor: roller conveyor or chain conveyor

8. palletizer (low level gantry palletizer, high level gantry palletizer, single column palletizer)

9. stretch film wrapping machine.

Flowchart

Raw water

↓

Water treatment system

↓

Ozone rinsing Blow molder

↓ ↓

|

Filling ← Product water rinsing ↓ Capping |

← Air conveyor ← PET empty bottle

← Cap elevator sterilization

↓

Air blow dryer

↓

Bottle body inkjet

↓

Light

↓

Sleeve labeling machine ← Label

↓

Full bottle conveying system

↓

Film packing machine

↓

Finished product storage

Above flow chart is only for reference, which can be amended by customer’s requirement.

VALIDITY OF THE OFFER

30 days from the date of quotation sent

DELIVERY

Approx. 60 days from order confirmation

PAYMENT

30% as deposit by T/T, 70% paid before shipment by T/T.

INSTALLATION &COMMISSIONING

The seller will dispatch one engineer to the buyer's factory for installation and commissioning and training, the buyer should be responsible for the room and board and the go-back air tickets and visa fee, and the allowance of 100 USD per day for each person each day.

NOTE

1. If delays occur due to the fault of either party involved, then any extracost shall be borne by the party at fault

2. The Customer is responsible for providing continuous supply of quality electricity for the duration of the installation, commissioning and test running, which must be available prior to the arrival of technicians from the Manufacturer.

SAMPLES

Sufficient quantity of product samples must be sent byCustomers toManufacturerwithin 15 days after order confirmation for technical clarification.Delays in sending the required samples may affect the delivery schedule of the machines, of which the Manufacturer bears no responsibility for the cost of sending the samples is at Customer's charge.

GUARANTEES

√ The guarantee covers the replacement f.o.c. of the parts that are comprised in the supply and those

acknowledged to bear manufacturing faults or are materials that contribute to the incorrect function of

the machine

√ Lilan guarantees the products supplied for a 12-month period as of from the date of the startup but

however, not more than 18 months from the date of the relative invoice.

√ As for the electrical and electronic parts, the guarantee lasts for 6 months from the startup date but

however, not more than 12 months from the date of the relative invoice.

√ Merchandise that is supplied under guarantee will be delivered with pre-paid freight and packaging

√ Other relevant guarantees kindly see the operation and appliance manuals sent with equipment.

Note:All the accurate technical data should be confirmed in the meantime contract is confirmed