Automatic PP PE PET HDPE Waste Recycling Machines Plastic Recycling Machine Double Stage

US $27,000.00-28,000.00 / set

1 set(s)Minimum order

plastic processed:

HDPE, HDPE/PP, PA, PE/PP, Lldpe, Polystyrene, ABS/PP, EVOH, wood-plastic, PPR, PP, FRPP/PVC, PVC, MLLDPE, LDPE, ABS, PET, EVA, PC, Polylactic Acid, EPS

output (kg/h):

200 - 250 kg/h

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

Gearbox, motor

place of origin:

ZHE

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | HDPE, HDPE/PP, PA, PE/PP, Lldpe, Polystyrene, ABS/PP, EVOH, wood-plastic, PPR, PP, FRPP/PVC, PVC, MLLDPE, LDPE, ABS, PET, EVA, PC, Polylactic Acid, EPS |

|---|---|

| output (kg/h) | 200 - 250 kg/h |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | Gearbox, motor |

| place of origin | ZHE |

| screw design | Single Phase |

| voltage | customized |

| dimension(l*w*h) | 10m*1m*2m |

| power (kw) | 80 |

| warranty | 1 Year |

| screw l/d ratio | 28:1, 28:1 |

| screw speed (rpm) | 50 - 80 rpm |

| Weight (KG) | 5000 |

| Application | Waste Plastic Recycling |

| Color | Customer Choice |

| Final product | Clean PP PE Pelletes |

| Voltage | 380V/440V/415V/customized |

| Pelletizing type | Strand Cutting |

| Motor | Wannan Motor |

| Feed way | Directly Feeding |

| Screw type | Single Srew |

| Recycle material | pp pe |

| Max. Capacity | 200 |

Product Detail

VR

VR

Product Overview

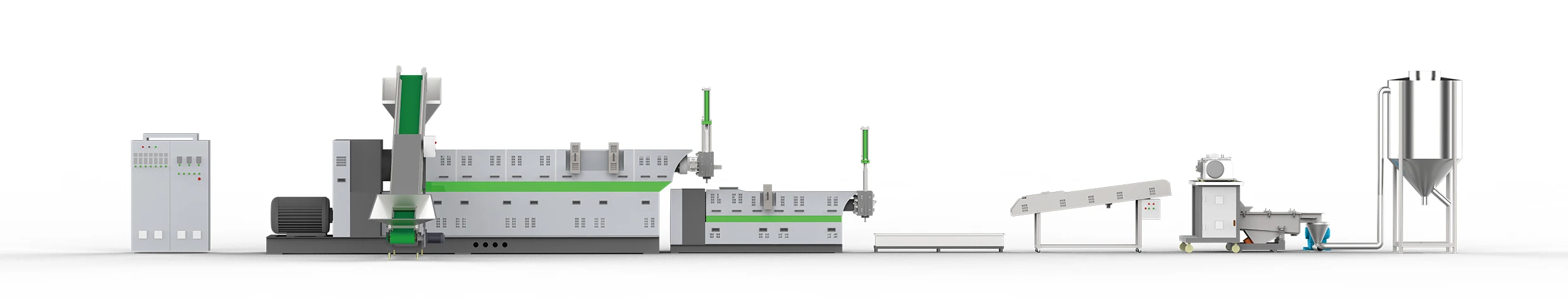

LDD series plastic pelletizing machine

Usage:

This machine can process a variety of thermoplastic plastics,such as PC,PA,PP,ABS,PE,POM,PET etc. Different from LDC series, this kind of machine has two even three stages.

Features:

LDD series is used for PP PE ABS PA PS PET crushed material extruding and granule-making. It adopt the two-step structure to meet the the double-layer filter purpose. It can effectively remove the impurities from the recycling material and fully exhaust the gas.It can produce ample,consolidated and fine luster granules.

This machine can process a variety of thermoplastic plastics,such as PC,PA,PP,ABS,PE,POM,PET etc. Different from LDC series, this kind of machine has two even three stages.

Features:

LDD series is used for PP PE ABS PA PS PET crushed material extruding and granule-making. It adopt the two-step structure to meet the the double-layer filter purpose. It can effectively remove the impurities from the recycling material and fully exhaust the gas.It can produce ample,consolidated and fine luster granules.

Youtube link:https://youtu.be/d2UDWOLrJHo?si=7H-JrXflF6VZYU6r

Products Description

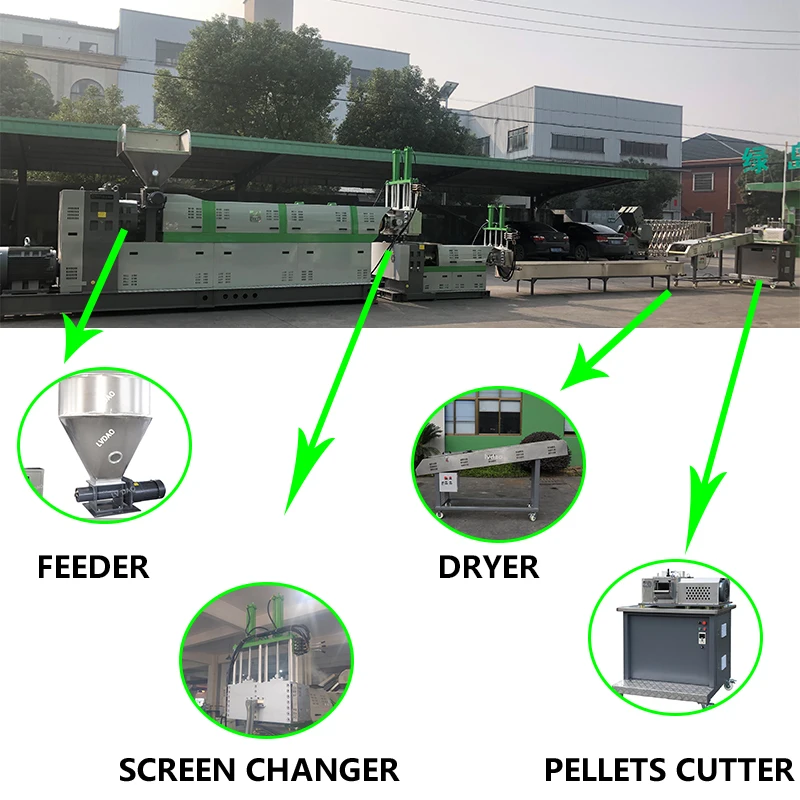

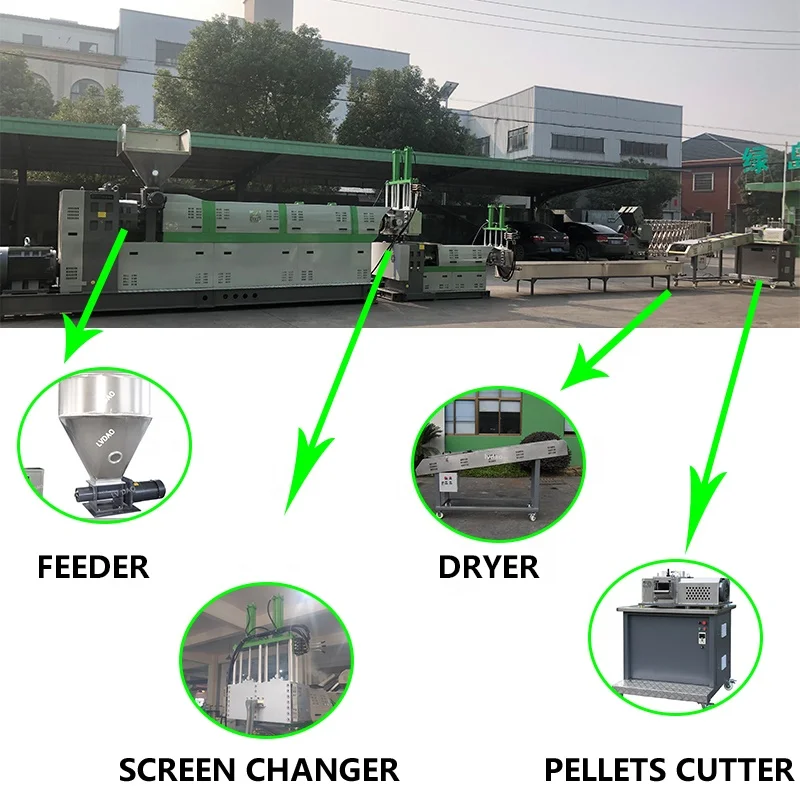

1. | Main Extruder |

2. | Vice Extruder |

3. | Cooling tank |

4. | Dry blower |

5. | Pellets cutter |

6. | Storage |

Main Extruder

Equip the feeder for hard scraps and flakes

Screw&barrel made by Nutrited 38CrMoAl

Hard teeth surface gearbox

Double screen changer

Vice Extruder

Screw&barrel made by Nutrited 38CrMoAl

Hard teeth surface gearbox

Double or single screen changer

Hard teeth surface gearbox

Double or single screen changer

Product Paramenters

Model | Screw dia. | Output | Main/Vice power | Long dia ratio |

LDD-SJP-100-95 | 100mm&95mm | 150-200kgh | 30/11kw | 28:1 10:1 |

LDD-SJP-120-110 | 120mm&110mm | 250-300kgh | 45/15kw | 28:1 10:1 |

LDD-SJP-140-130 | 140mm&130mm | 350-400kgh | 75/18.5kw | 28:1 10:1 |

LDD-SJP-160-150 | 160mm&150mm | 450-500kgh | 110/30kw | 28:1 10:1 |

LDD-SJP-180-160 | 180mm&160mm | 500-600kgh | 132/37kw | 28:1 10:1 |

Above Paramenters take ABS as an example

More model information contact us pls.

Recommend Products

Company Profile