Automatic Straw Making Machines Plastic Plastic Extruder Drinking Straw Making Machine

US $10,500.00-10,800.00 / set

1 set(s)Minimum order

place of origin:

Jiangsu, China

brand name:

shinestraw

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Engine, Bearing, Gear

voltage:

380

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Jiangsu, China |

|---|---|

| brand name | shinestraw |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gear |

| voltage | 380 |

| power(w) | 32 |

| dimension(l*w*h) | 9*2*2 |

| warranty | 1 Year |

| Weight (KG) | 1200 |

| Name: | PLA PP PE Plastic Extruder Drinking Straw Making Machine |

| Application: | Plastic Straw Making |

| Capacity: | 30,000~40,000pcs/h |

| capacity: | fast and stable |

| Cutting System: | Frequency Conversion |

| Advantage | cheap |

| Straw Diameter: | Custiomized |

| Final Products: | Drink Straw |

| Straw color: | 1-3 |

| Raw material: | PP / PE/PLA |

Product Detail

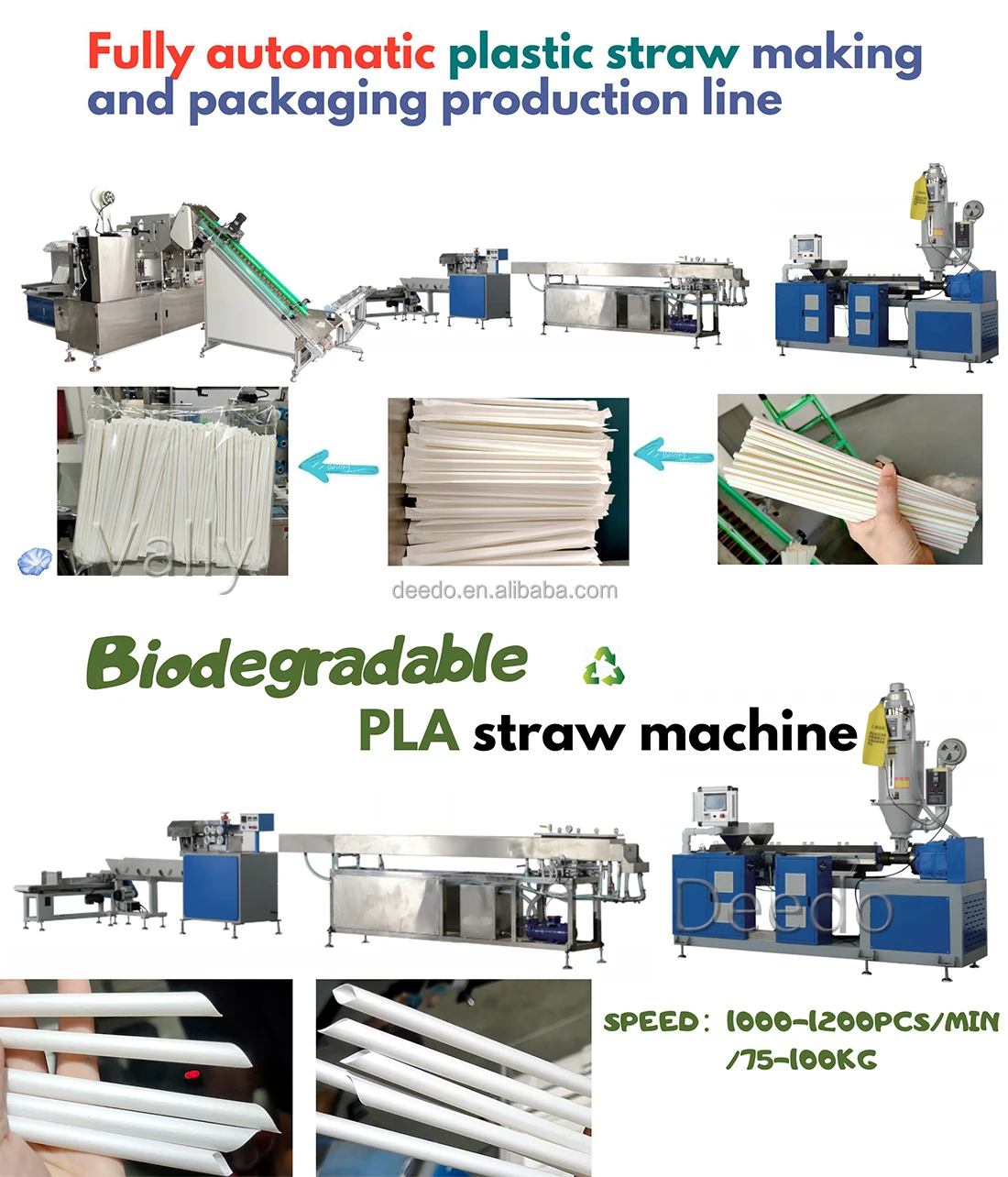

Automatic straw making machines plastic Plastic Extruder Drinking Straw Making Machine

Our factory

About us

SUZHOU DEEDO MACHINERY was established in 2014, has been established for 10 years.

Our main products are as follows:

Our main products are as follows:

1.High speed plastic straws machine.

2.High speed paper straws machine.

3.Paper stick machine.

4.Jumbo paper slitting rewinding machine.

5.straw packing machine:

-Single straw packing machine

--Group straw packing machine

--Straw bending machine

--U straw packing machine

--I straw packing machine

--Straw carton box packing machine

--Paper straw bevel cutting machine.

Our equipment is exported to more than 80 countries and regions including the United States,the United Kingdom, Germany.Sweden,Switzerland, Canada, Mexico, Turkey, Bulgaria, Croatia, Macedonia, Belgium, Vietnam, India,South Korea, Indonesia Ecuador,Ukraine, the Middle East and Africa...

2.High speed paper straws machine.

3.Paper stick machine.

4.Jumbo paper slitting rewinding machine.

5.straw packing machine:

-Single straw packing machine

--Group straw packing machine

--Straw bending machine

--U straw packing machine

--I straw packing machine

--Straw carton box packing machine

--Paper straw bevel cutting machine.

Our equipment is exported to more than 80 countries and regions including the United States,the United Kingdom, Germany.Sweden,Switzerland, Canada, Mexico, Turkey, Bulgaria, Croatia, Macedonia, Belgium, Vietnam, India,South Korea, Indonesia Ecuador,Ukraine, the Middle East and Africa...

Products Description

Applications:Food industry: Drinking Straw, Coffee stirring stick, Lollipop sticks, candy floss sticks, ice cream bars, etc.

Industrial applications: cartridge, pen, spray straw, cotton swab stick, toys tube, threading pipe, tube, brake tubes and other small profile Irrigation System: Micro-drip irrigation pipe, etc.

Drinking Straws: 30,000~40,000pcs/h

Cotton swab sticks: 80,000pcs/h

Pen Refills: 60,000pcs/h

Material: PP, PE

Cutting edge: 90°/90°,90°/45°,90°/60°,45°/45°,60°/60°

Color:Single / Two / Three

Operator:One operator is sufficient to run the line

Industrial applications: cartridge, pen, spray straw, cotton swab stick, toys tube, threading pipe, tube, brake tubes and other small profile Irrigation System: Micro-drip irrigation pipe, etc.

Drinking Straws: 30,000~40,000pcs/h

Cotton swab sticks: 80,000pcs/h

Pen Refills: 60,000pcs/h

Material: PP, PE

Cutting edge: 90°/90°,90°/45°,90°/60°,45°/45°,60°/60°

Color:Single / Two / Three

Operator:One operator is sufficient to run the line

Product Paramenters

Model | SJ50 | SJ50/25 | SJ50/25/25 | ||||

Color | Single | Two colors | Three colors | ||||

Description | 1. Main parts are: extruder, cooling water tank, vacuum shaping equipment, air compressor, hauling cutting system, single color, bicolor or tricolor pipes can be realized. | ||||||

2. Main screw diameter: 50mm, important parts such as screw and cylinder adopts superior alloy steel with nitrogen treatment, 38CrMoAlA (nitrogen treatment, depth 0.2~0.7mm) | |||||||

3. Aspect ratio: 28:1 | |||||||

4. Diameter of sub-screw:25mm, Aspect ratio: 20:1 | |||||||

5. Extruding power: 11kw (frequency conversion control) | |||||||

6. The die undergoes nitride hardening treatment for a long service time | |||||||

7. The water tank and the surface of cutting machine are made of 304 stainless steel | |||||||

8. The main extruder’s screw designed to suit plastic material specified. Tube dies head assembly manufactured in tool steel. | |||||||

9. All the electrical parts use SCHNEIDER or SIEMENS or Delta | |||||||

Model | SJ50 | SJ50/25 | SJ50/25/25 | ||||

Color | Single | Two colors | Three colors | ||||

Power Supply | Main screw | 380v ,3phase,50hz,7.5kw(VFD) | 380v ,3phase,50hz,7.5kw(VFD) | 380v ,3phase,50hz,7.5kw(VFD) | |||

Sub-screw | / | 0.75kw | 0.75×2kw | ||||

Heating | 7kw | 9.56kw | 12kw | ||||

Hauling motor | 0.75kw(VFD) | 0.75kw(VFD) | 0.75kw(VFD) | ||||

Cutting motor | 0.75kw(VFD) | 0.75kw(VFD) | 0.75kw(VFD) | ||||

Total power | 16.5kw | 20kw | 22.5kw | ||||

Temperature Controller | 5 sets | 8 sets | 11 sets | ||||

Electric control cabinet | 1 set | 1 set | 1 set | ||||

Automatic Counting Device | 1 set | 1 set | 1 set | ||||

Way of Hauling | By rubber roller | By rubber roller | By rubber roller | ||||

Way of cutting | Rotatory cutting length range 50-300mm | Rotatory cutting length range 50-300mm | Rotatory cutting length range 50-300mm | ||||

Cooling water tank | Usually 4.4m, can be adjusted up&down, right &left, forward&backward. Made of superior stainless teel | Usually 4.4m, can be adjusted up&down, right &left, forward&backward. Made of superior stainless teel | Usually 4.4m, can be adjusted up&down, right &left, forward&backward. Made of superior stainless teel | ||||

Stick Spec | Material | PLA PP PE etc | PLA PP PE etc | PLA PP PE etc | |||

Stick Diameter | 2mm~13mm can be custiomized for special requirement | 2mm~13mm can be custiomized for special requirement | 2mm~13mm can be custiomized for special requirement | ||||

Stick Length | 5cm-80cmCustomizable | 5cm-80cmCustomizable | 5cm-80cmCustomizable | ||||

Speed | 600~1000pcs/min (product rate : 20kg/h-30kg/h) | 600~1000pcs/min (product rate : 20kg/h-30kg/h) | 600~1000pcs/min (product rate : 20kg/h-30kg/h) | ||||

Straight or spiral | √ | √ | √ | ||||

Cutting End | 90°/90°,90°/45°,90°/60°,45°/45°,60°/60 | 90°/90°,90°/45°,90°/60°,45°/45°,60°/60 | 90°/90°,90°/45°,90°/60°,45°/45°,60°/60 | ||||

Dimension | L*W*H | 8m*1m*1.7m | 8m*1.5m*1.7m | 8m*2m*1.7m | |||

Weight | 1500kg | 1700kg | 2000kg | ||||

Details Images

Extruder:Die mould and heating ring

Diameter range (OD): 2-12mm;

Wall thickness: 0.08-1mm;

Material of the mould body: steel 45#;

Material of inner mould parts:40Cr

Wall thickness: 0.08-1mm;

Material of the mould body: steel 45#;

Material of inner mould parts:40Cr

Die mould and heating ring

Extruder mold

Delixi electric accessories

Delta Motor

Water cooling tank:

Function: calibrate the outer diameters andcooling pipe primarily;

Material: stainless steel, SUS304;

Cooling mode: spray-pouring cooling;

Pouring areas: 3 in 4 out.

Material: stainless steel, SUS304;

Cooling mode: spray-pouring cooling;

Pouring areas: 3 in 4 out.

Haul off and cutting machine

1.Available pretrial length: 5-800mm;

2.Straight line straw.

3.Speed adjusting mode: frequency conversion;

4.Hauling speed: 0-250.

2.Straight line straw.

3.Speed adjusting mode: frequency conversion;

4.Hauling speed: 0-250.

Cutting straw

This can cut sharp ends and straight straws, cutting sharp ends: 90 °/90 °,90 °/45 °,90 °/60 °,45 °/45 °,60 °/60 °

Counting device,Easy to operate

Straw cutting bevel

Straw Cut Flat

twisted cross line

twisted cross line straw

L-shaped collection straw

Lollipop stick

PLA straws

Cotton swab stick

2 colors bevel straw

cut bevel straw

2 colors

cut flat straw

Straw Feeder machine

Send straws into next step automatic.No need to get it manually.

Universal straw diameter 2-14mm.

Single Straw Packing Machine

1.with 2 colors printing function;

2. wrap individual straws

2. wrap individual straws

3 with location traction function (optional);

4 speed around 500-700pcs/min.

4 speed around 500-700pcs/min.

Single packaging straw

1.2-color printing, fixed position.

2.Clear pattern

Single straw machine + multiple straw packaging machine

1. Fully automatic packaging production line, no manual contact with straw.

2.speed around 1400pcs/min.

3.Single package, then multiple packages.

Group Straw Packing

First single packaging Straw, then bag packaging straw .

Group Straw Packing Machine

1.speed around 1400pcs/min.

2.Bulk straw packaging.

Group Packing Straw

200pcs/bag,The quantity can be set according to the needs, the minimum is 50 pcs/bag and the maximum is 500 pcs/bag.

Type I straw packaging machine

1.one Machine,one diameter

Straw type I packaging

Straw bending packaging machine

1.One machine, one diameter.

2.12group/18group

bended Straw

U-shaped straw packaging machine

U-shaped straw

Artistic straw machine

1.One machine, one diameter.

2.speed 150-200pcs/min.

3.Straw diameter: customizable.

Artistic straw

teeth qty:58-60.

straw thickness:0.14-0.2mm.

Straight straw length: 270-340mm.

Recommend Products

FAQ

Business card

Thank you very much for seeing here. If you are interested in our products, please contact me and I will be happy to discuss it with you,thank you!

HOW TO FIND Deedo MACHINE?

* Search Alibaba, Made in China, Google, Youtube and Facebook.

* Visit exhibition in different countries.

* Send Deedo Machine an request and tell your basic inquiry.

* Deedo Machine sales manager will reply you in short time and add instant chatting tool.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

* If we can fullfill your request and you interested in our products, you may pay a visit to DeedoMachine site.* The meaning of visiting supplier, because seeing is believing, DeedoMachine with own manufacture and developed& research team,we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

* Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

* By letter of credit, you can lock the delivery time easily.

* After the factory visit, You can ensure the facticity of our bank account.

HOW TO ENSURE THE QUALITY!

* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

* Each component before assembly needs strictly control by inspecting personnel.

* Each assembly is in charged by a master who has working experience for more than 10years.

* After all the equipment are completed, we will connect all the machines and run the full production line to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE

* After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

* After the commissioning, we will package the equipment by standard export package for shipment.

* According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

* Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

HOW TO FIND Deedo MACHINE?

* Search Alibaba, Made in China, Google, Youtube and Facebook.

* Visit exhibition in different countries.

* Send Deedo Machine an request and tell your basic inquiry.

* Deedo Machine sales manager will reply you in short time and add instant chatting tool.

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

* If we can fullfill your request and you interested in our products, you may pay a visit to DeedoMachine site.* The meaning of visiting supplier, because seeing is believing, DeedoMachine with own manufacture and developed& research team,we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

* Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

* By letter of credit, you can lock the delivery time easily.

* After the factory visit, You can ensure the facticity of our bank account.

HOW TO ENSURE THE QUALITY!

* In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

* Each component before assembly needs strictly control by inspecting personnel.

* Each assembly is in charged by a master who has working experience for more than 10years.

* After all the equipment are completed, we will connect all the machines and run the full production line to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE

* After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

* After the commissioning, we will package the equipment by standard export package for shipment.

* According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

* Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

Packing & Delivery