C140 Villa Rollform Light Gauge Steel Form Keel Rolling Metal Profile Roll Turkey Frame Cad Long LGS Machine

US $60,000.00-66,800.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Engine, motor

Work Pressure:

normal pressures

Place of Origin:

Fujian, China

Brand Name:

XHH

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, motor |

| Work Pressure | normal pressures |

| Place of Origin | Fujian, China |

| Brand Name | XHH |

| Voltage | 380V/50HZ/3PH |

| Power | 11KW |

| Dimension(L*W*H) | 5100*1600*1100mm |

| Weight | kg |

| Warranty | 1 Year |

| Key Selling Points | Easy to Operate |

| features | post punching and cuttinng |

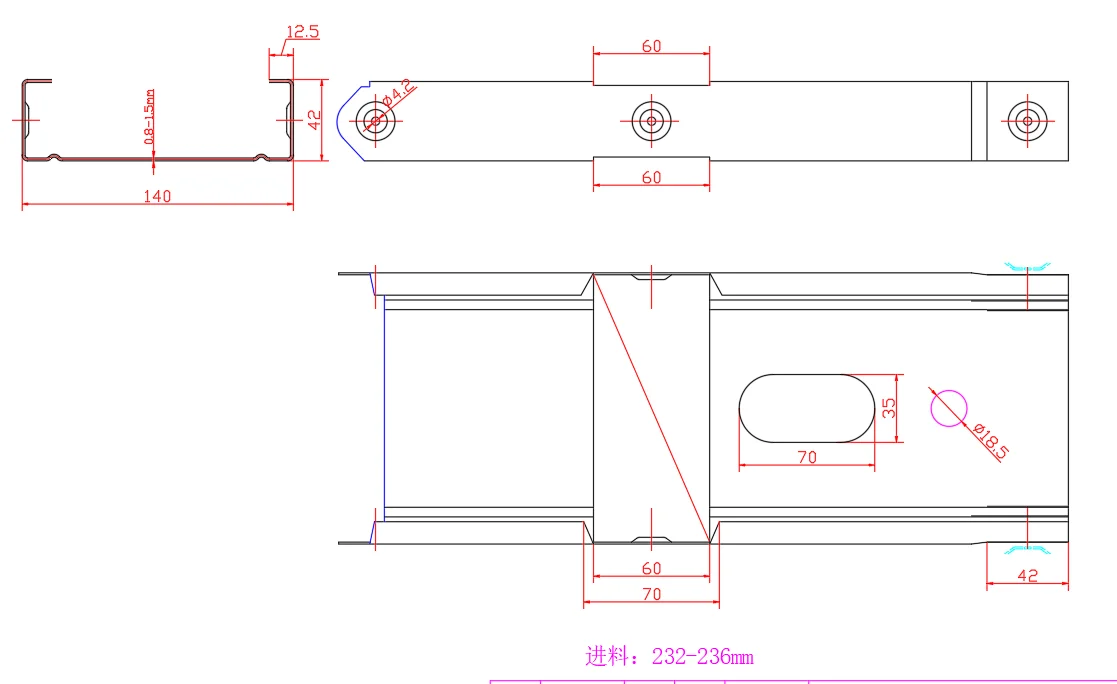

| feeding width | 233mm |

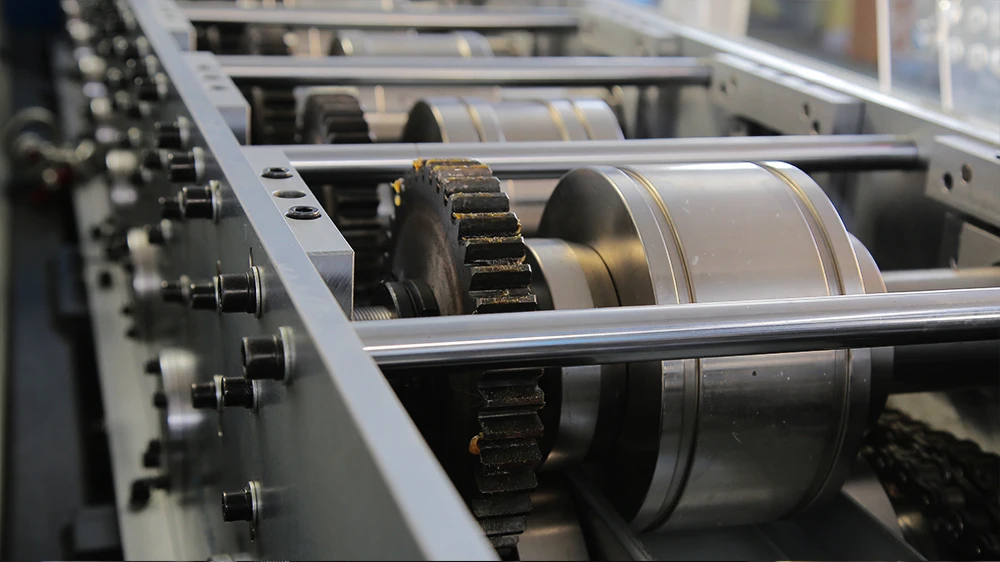

| Forming steps | 12steps |

| effective width | 140mm |

| thickness | 0.8mm-1.4mm |

| dipth of section | 41mm |

| lip | 9mm |

| punch tolerance | ±1mm |

| cutting tolerance | ±0.7mm |

Product Detail

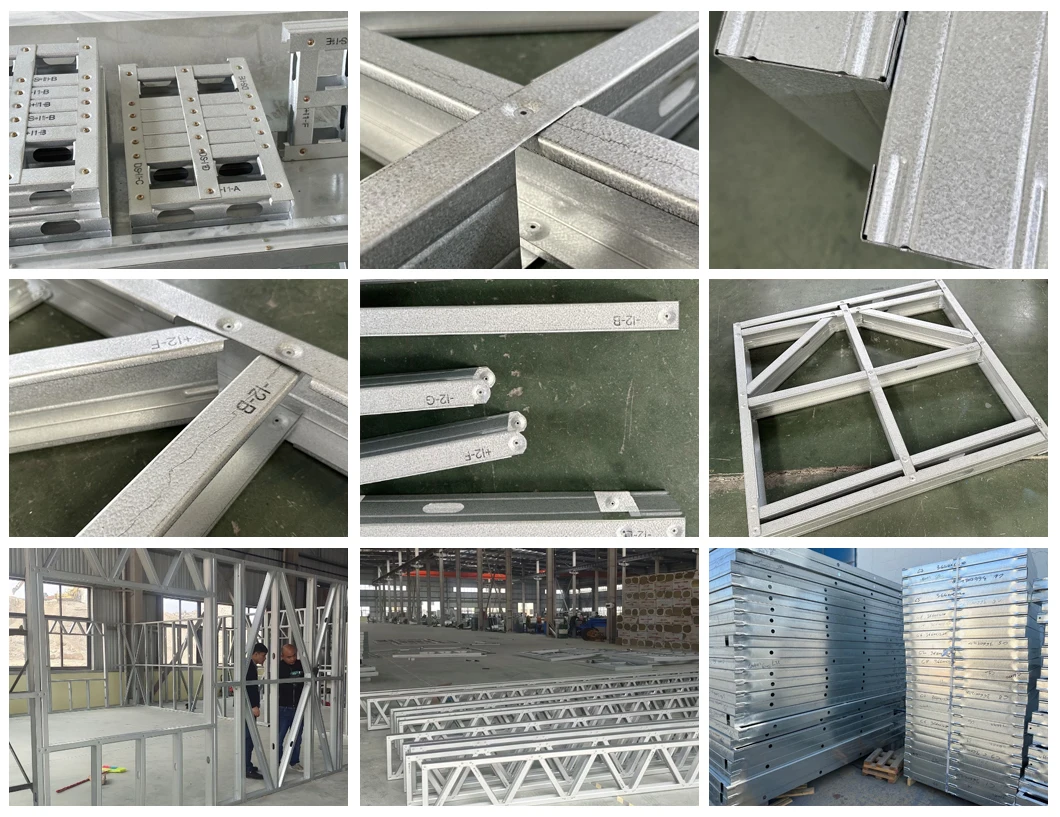

Light gauge steel framing systems consist of structural frames fabricated using cold formed steel sections. They can be used throughout a structure, including load-bearing exterior walls, non-load bearing interior walls, floor joists, curtain walls and roof trusses.The system automatically generates wall and floor fabrication drawings, structural layouts, cut lists and other material reports.By automating these processes, manufacturers save a lot of time in drafting, material reporting, data entry, manufacturing, and correcting all errors.

Top Selling

Suitable for 1-3 floors building

Cheap Discount

Suitable for beginners

Multiple Profile

Suitable for multiple floor building

Products Description

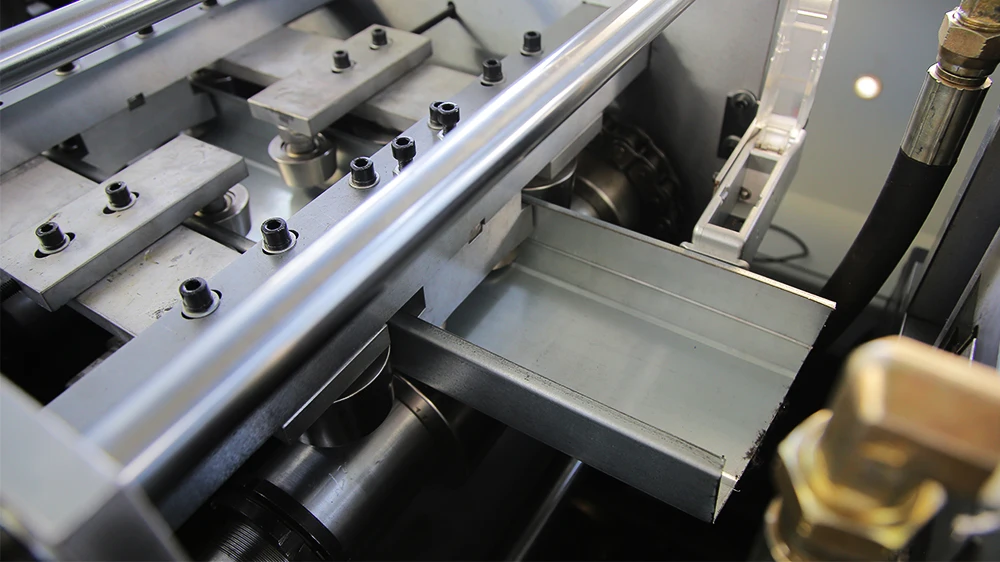

Fasting Working Speed:4-5T/8Hours,2700M/H

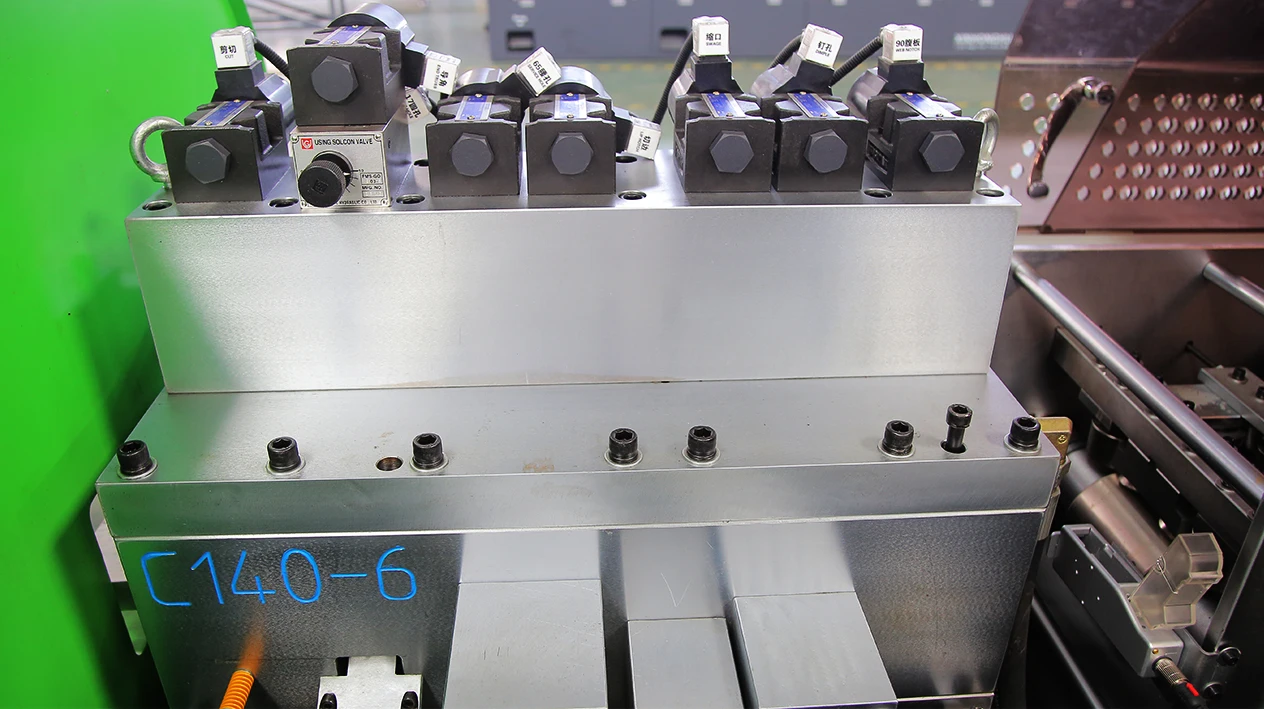

Post-Punching Mould & Post-Cutting

High Production Speed & High Precision

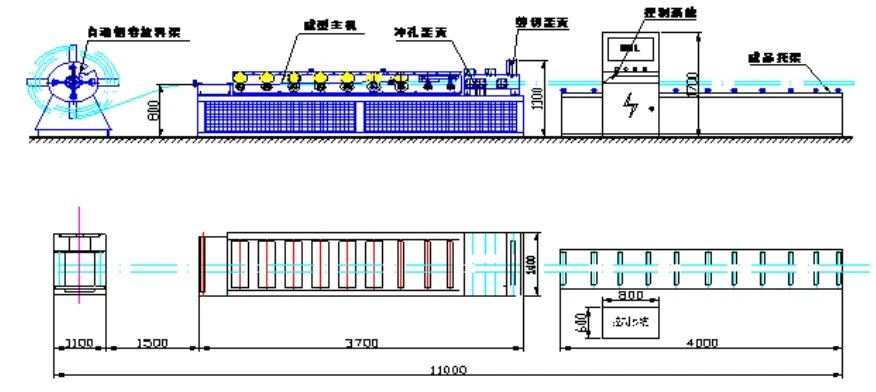

Working Flow:

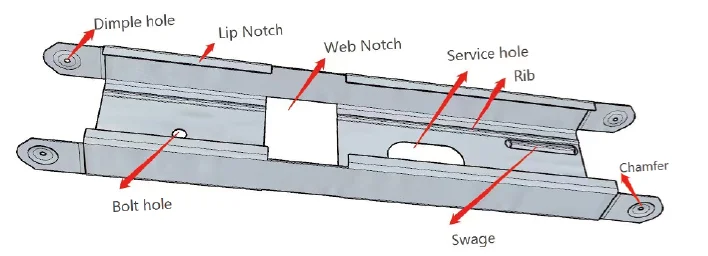

Profile Dimensions:

(1) Dimple hole

(2) Lip Notch

(3) Web Notch

(4) Service hole

(5) Bolt hole

(6) Swage

(7) Rib

(8) Chamfer

Profile Model | C Section(mm) | Thickness | ||||

Web | Flange | Lip | ||||

C140 | 140 | 41 | 9 | 0.8-1.5mm | ||

Profiles can be designed according to customers requirements

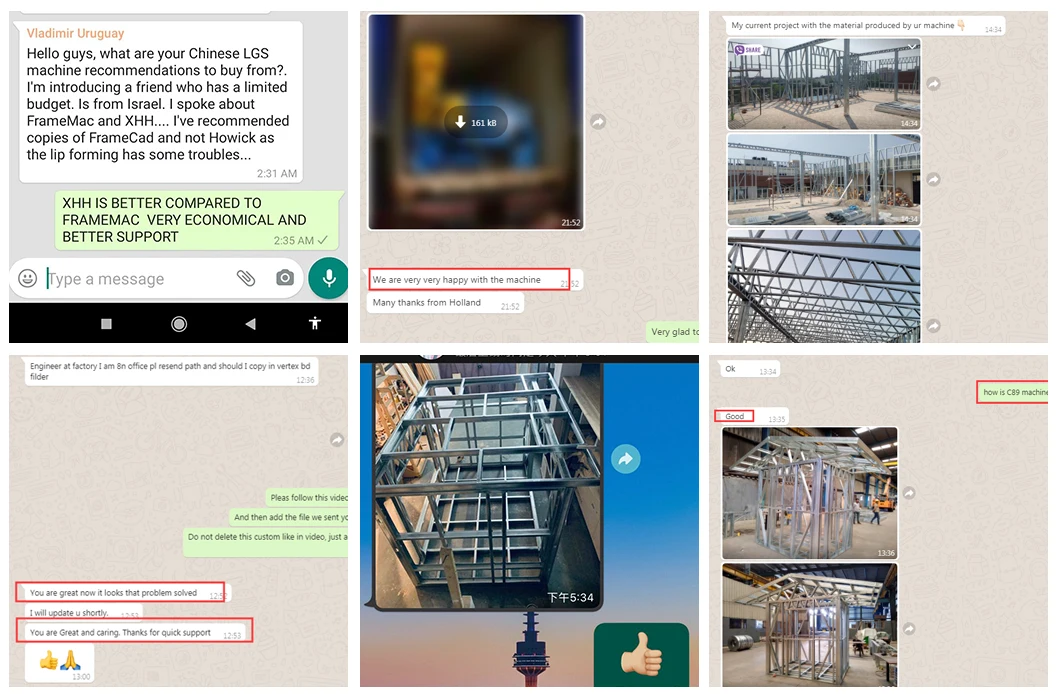

Real Customer Feedback:

Real Customer Project:

Light gauge steel framing machines are used to create the structural framework of buildings by cold forming steel sections into columns, beams, studs, tracks, and joists. These machines can be used in a variety of applications, including:residential and commercial construction,Prefab and modular house, warehouses and manufacturing facilities etc.

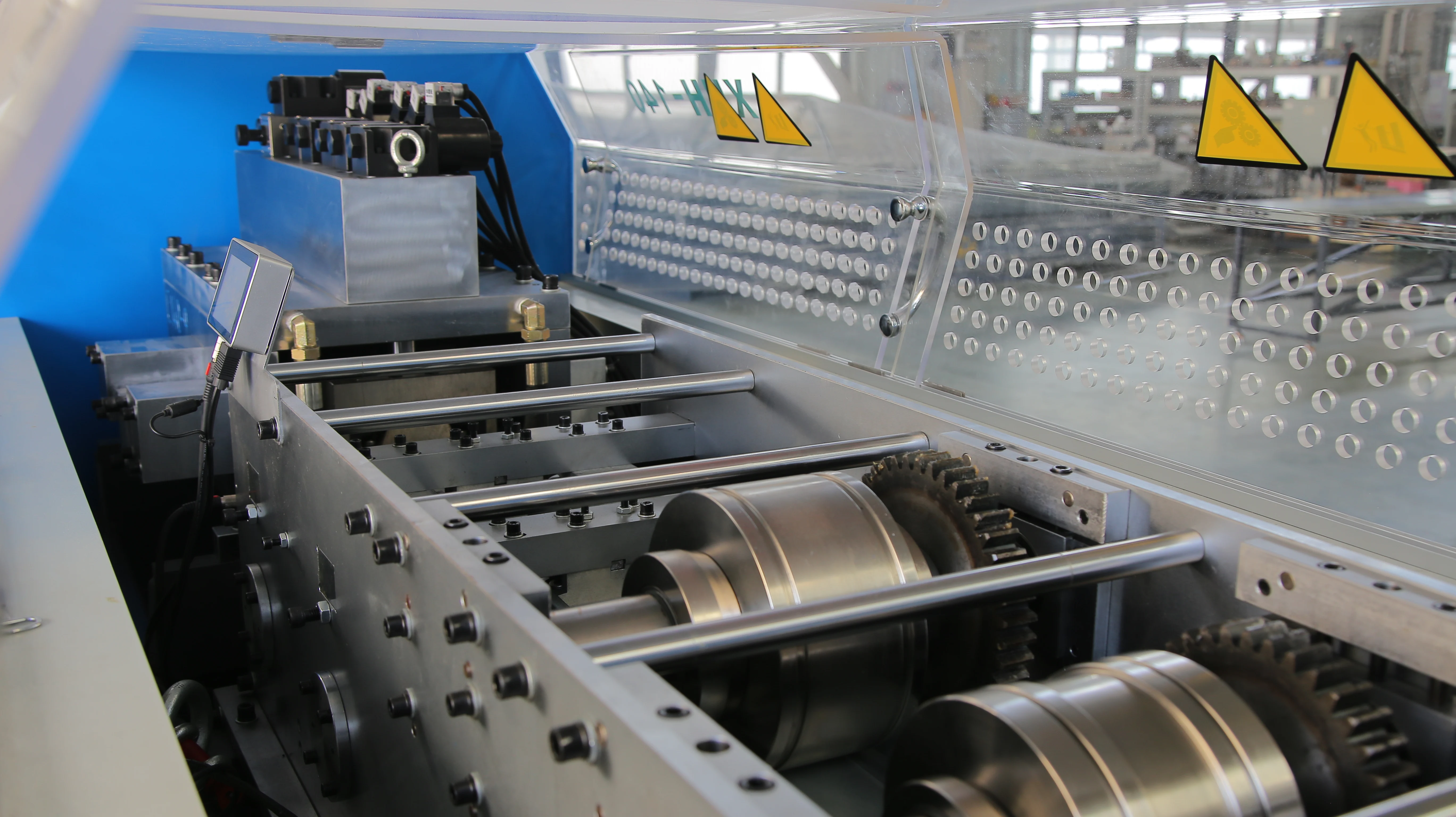

Machine Picture:

Technical Parameters:

Size | C140 |

Dimension | 5100*1600*1100mm |

Main Servo Motor Power | 11KW |

Hydraulic Motor | 11kw |

Forming Steps | 12 Steps |

Voltage | 380V/50HZ/3PH |

Material Width | 235mm |

Tolerance for cutting and punching | ±0.5mm |

Tolerance for forming | ±1mm |

Control System | IPC Computer Controlling System |

Machine Components:

No. | Items | Quantity | |

1 | Steel Strip Uncoiler | 1 | |

2 | Roll Former Machine | 1 | |

3 | Hydraulic Puncher/Cutter | 6 | |

4 | Hydraulic Station | 1 | |

5 | Design Software | 1 | |

6 | Controlling System | 1 | |

7 | Label Printer | 1 | |

8 | Layout Table | 1 | |

9 | Tool | ||

10 | Spare parts | ||

11 | User Manual 1 copy | ||

Service:

1. Factory Lifetime Service:offer technical support for the entire life of our machines.

2. Customized Profile:can design the profile according to customer request.

3. One-Year Guarantee Period:we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

4. Overseas Services Optional:we can send our technicians to install and train the workers in the clients' factories with extra cost.

2. Customized Profile:can design the profile according to customer request.

3. One-Year Guarantee Period:we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

4. Overseas Services Optional:we can send our technicians to install and train the workers in the clients' factories with extra cost.

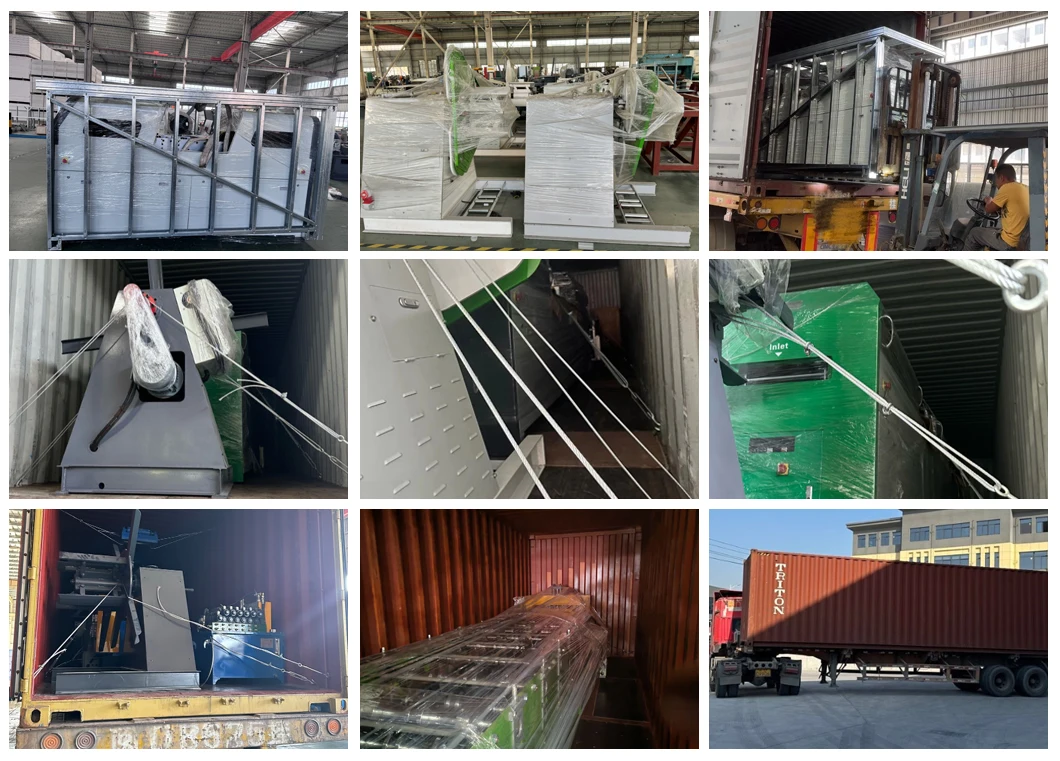

Package:

For different machines or production line parts, we have different packing solutions:

- For the machine or production line, we will use plastic film to cover and wrap. Then will be loaded to the container by forklift or crane.

- For the key parts such as the roll forming rollers set, we will use the metal frame to package.

All Steadily fastened in the container in a suitable manner with steel ropes and locks, being suitable for long-distance transportation.

- For the machine or production line, we will use plastic film to cover and wrap. Then will be loaded to the container by forklift or crane.

- For the key parts such as the roll forming rollers set, we will use the metal frame to package.

All Steadily fastened in the container in a suitable manner with steel ropes and locks, being suitable for long-distance transportation.

Company Profile

XIAMEN XINHONGHUA MACHINERY CO. LTD.(FUJIAN XINHONGHUA MACHINERY CO. LTD) was founded in 2004.as the earlier company which engaged in the manufacture of cold roll forming machines,after the reform and innovation of more than 19 years,and on basis of manufacture of modern management concepts,strong technology,advanced production technology,perfect service system,we have been currently in the domestic leading position,and as good competitor among the same industry of world.

Our company is located in the beautiful scenery,nice island of Xiamen.And have variety of products with stable performance,Always pay attention to improve the existing products and research and develop the new products.We have nearly 100 kinds of professional and technical personnel,with its strong ability of product design and development,to ensure a high level design of our product.For our products with light structure, reasonable design and updating styles,so we become well-know in the steel structure industry.

Main Products

FAQ

Q:Are you a trading company or manufacture.

A:We are a factory.

Q:Do you provide samples ? ls it free or extra ?

A:Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.We couldoffer the sample for free charge

Q:Where is your factory located?

A:Our factory is located in Xiamen City, Fujian Province, China. You are warmly welcome to visit us !

Q:Can you make the machine according to my design or prototype?

A:Yes. We have an professional designer for working out the most suitable design and productionplan for the machine that you are going to book with us.

Q:How can I trust you that machines pasted testing running before shipping?

A:1) We record the testing video for your reference.2) You are welcome to visit us and test machine in our factory.

Q:Do you provide instaling and training overseas?

A:Overseas machine install and worker training services are optional.

Q:How is your after sales support?

A:We provide technical support on line as well as overseas services by skillful technicians

Q:Guarantee period?

A:Within one year since the date of finishing commissioning