Ceramic Ball Mill for Grinding Feldspar Quartz Glass Refractory Material with Alumina Ceramic Tiles

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine |

| Type | ceramic ball mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 0.05 |

| Place of Origin | Henan, China |

| Brand Name | XKJ |

| Dimension(L*W*H) | 2079*677*677mm |

| Weight | 800 KG |

| Warranty | 1 Year |

| Product name | Alumina ceramic tile ceramic ball mill |

| Application | Non-polluting powder grinding |

| Installation | Provide foundation drawings |

| Grinding material | 92% alumina ceramic ball grinding |

| Grinding way | Dry ball mill grinding |

| Delivery time | 30-35days |

| Max feeding size | 30-50 Mm |

| Discharge size | 0.074-0.6 |

| Certification | ISO 9001:2024 |

| After-sales service | 12 Months Guarantee |

Product Detail

tkwQuartz Sand Stone Wet Dry Grinding Machine Ceramic Ball Mill

Ceramic ball mill is also called ball mill and intermittence ball mill, why under the name of batch and intermittence ? Since the batch mill has only one hole in the middle of the cylinder, so feeding the raw materials at a time, then grinding, until all the materials get me what size you need discharging all the raw materials for grinding production depends on the milling machine time.

600×700 model dry ceramic ball mill

The 600×700 ceramic ball mill is a small-yield ball mill with a 92% alumina ceramic lining brick and a 92% alumina ceramic ball for grinding. The ball mill can be filled with 50kg of material at a time, and then ground until the desired material size is ground out, take it out, put the material in again, and repeat the operation.

1200×1420 dry ceramic ball mill

The 1200*1420 ceramic ball mill is a small-yield ball mill with a 92% alumina ceramic lining brick and a 92% alumina ceramic ball for grinding. The ball mill can be filled with 500kg of material at a time, and then ground until the desired material size is ground out, take it out, put the material in again, and repeat the operation.

1400×1800 dry ceramic ball mill

The 1400*1800 ceramic ball mill is a small-yield ball mill with a 92% alumina ceramic lining brick and a 92% alumina ceramic ball for grinding. The ball mill can be filled with 1000kg of material at a time, and then ground until the desired material size is ground out, take it out, put the material in again, and repeat the operation.

Ceramic tiles and ceramic balls

Technical Parameter ceramic ball mill

| Model | Cylinder size(mm) | Loading weight(t) | Cylinder RPM(r/min) | Motor power(kw) | Weight(t) |

| 0.2T | Φ910×1120 | 0.2 | 35 | 2.2 | 1.9 |

| 0.5T | Φ1200×1420 | 0.5 | 31.45 | 4 | 2.5 |

| 1T | Φ1400×1800 | 1 | 27 | 7.5 | 3.2 |

| 1.5T | Φ1800×2100 | 1.5 | 23 | 11 | 4.5 |

| 2.5T | Φ2200×2200 | 2.5 | 20 | 18.5 | 6.5 |

| 3T | Φ2200×2600 | 3 | 20 | 22 | 7.3 |

| 5T | Φ2500×3000 | 5 | 16 | 37 | 13.2 |

| 8T | Φ2800×3400 | 8 | 13.8 | 45 | 19.5 |

| 10T | Φ2800x4000 | 10 | 13.8 | 55 | 20.2 |

| 15T | Φ3000x5000 | 15 | 13 | 75 | 26.7 |

| 18T | Φ3100×5000 | 18 | 12 | 90 | 28.5 |

| 19T | Φ3200x4700 | 19 | 12 | 110 | 29.6 |

| 20T | Φ3200×5800 | 20 | 11 | 110 | 30.5 |

| 30T | Φ3400×6500 | 30 | 11 | 110 | 34.3 |

| 40T | Φ3600x7000 | 40 | 11 | 132 | 38.2 |

| 50T | Φ3800×8000 | 50 | 11 | 200 | 45.1 |

| 60T | Φ4000×8500 | 60 | 10 | 200 | 52.2 |

Ceramic Ball Mill

Working environment of ceramic ball mill

24 hours online at any time to answer for you

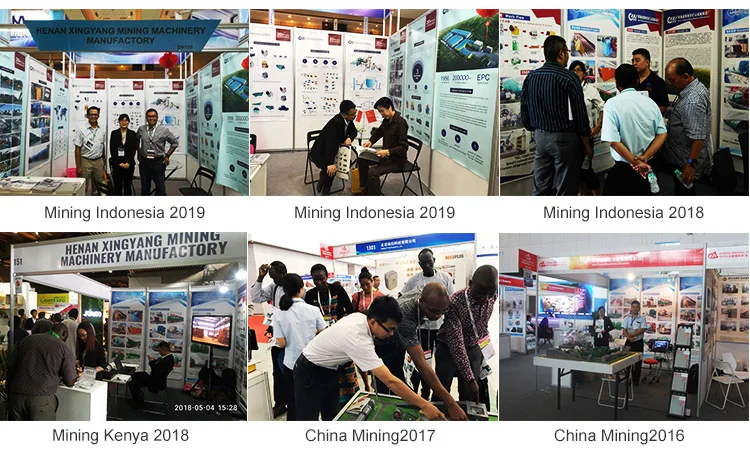

Henan Xingyang Mining Mechanics manufacturer is a professional manufacturer of inflatable boats, stone crushing machine for plastic and mining machinery from 1956. Our machines are widely used in the non-iron mining industry, building materials, road construction, water management and cement industry. Rich experience make us well aware of what you need. We can develop, we can help you create a complete set of processing equipment from 30TPD-3000TPD.

At the same time, we have four casting factories, which specializes in producing wear parts for our customers. In the event that your device is not manufactured by our company, please provide us with the fast-wearing parts of the drawing.

1. What is your delivery time for your car?

Information about the delivery time is provided within 20-30 working days. But if the project is very large and customers talk about having some special requirements about the equipment, the delivery time will be extended.

2. What payment methods do you accept?

Payment terms L/C, T/T, D/A, D, documentary collection and much more.

3. What is the minimum order size of your machine?

1 set. Our service will be in order to meet the needs of each customer.

4. How long is the warranty period about the machine?

Our machines warranty period is 1 year. Fast-wearing parts and problems coursed by the employee, incorrect control operation are not included in the package.

5. What is the minimum quantity for your company's post-sales service?

We will provide you with a drawing of the base in order for customers to install. In addition, we can provide installation maintenance, workers, service training, etc.

6. Can you provide me with fast-wearing parts?

We have four casting factories, which specializes in producing fast-wearing parts for our customers. In the event that your device is not manufactured by our company, please provide us with the fast-wearing parts of the drawing.

7. Can you provide me with a solution and your price offer?

Sure. Please tell us your details about the project, raw materials, capacity, max feeding size, output size, finished product usage, etc.