China Factory Supply 2 T/Hr Gold Ore Ball Mill Grinding Machine Mini Sag Ball Mill 5 Ton Ball Mill

US $5,500.00-6,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Engine, motor

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

1-150

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine, motor |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1-150 |

| Place of Origin | Henan, China |

| Brand Name | The Nile |

| Weight | 1100 KG |

| Warranty | 1 Year |

| Product name | Ball bill |

| Color | Customer's Request |

| Power | 130kw |

| Function | grinding |

| Advantage | High Working Effiency |

| Price | Competetive (can Discuss |

| Feeding size | <25 |

| Capacity | 3.5-4.5 |

| Ball weight | 13t |

| Main reducer | ZD40 |

Product Detail

Product Description

The dry ball grinder mill is a cylindrical tube mill, which is widely used in the production industries of cement, new building materials, silicate products, refractory materials, ferrous and non-ferrous metal advantage, and glass ceramics. It has many advantages such as large single machine capacity, long service life, energy saving and environmental protection, and simple operation.

working principle

The main body of the dry ball grinding mill is a low-speed rotating cylinder mounted horizontally on two large bearings. The ball mill is decelerated and driven by a motor through a reducer and surrounding large gears, or a low-speed synchronous motor is directly decelerated through a surrounding large gear to drive the rotating part to rotate. The cylinder is equipped with steel balls with appropriate grinding media. The grinding medium is lifted to a certain height under the action of centrifugal force and frictional force, and falls in a state of throwing or venting. The ground material continuously enters the inside of the cylinder through the feeding port, is crushed by the moving grinding medium, and is discharged out of the machine through the force of overflow and continuous feeding for the next process processing.

The main body of the dry ball grinding mill is a low-speed rotating cylinder mounted horizontally on two large bearings. The ball mill is decelerated and driven by a motor through a reducer and surrounding large gears, or a low-speed synchronous motor is directly decelerated through a surrounding large gear to drive the rotating part to rotate. The cylinder is equipped with steel balls with appropriate grinding media. The grinding medium is lifted to a certain height under the action of centrifugal force and frictional force, and falls in a state of throwing or venting. The ground material continuously enters the inside of the cylinder through the feeding port, is crushed by the moving grinding medium, and is discharged out of the machine through the force of overflow and continuous feeding for the next process processing.

Technical Data

Model | Ball loading (t) | Feed size(мм) | capacity t/h | Performance engine power (kw) | Weight T | |

Ф1200×4500 | 6.5 | ≤25 | 1.4-2 | 45 | 13.1 | |

Ф1500×5700 | 13 | ≤25 | 3.5-4.5 | 130 | 24 | |

Ф1830×6400 | 21.6 | ≤25 | 5.5-6.5 | 210 | 38 | |

Ф1830×7000 | 23.5 | ≤25 | 6-7 | 210 | 43 | |

Ф2200×6500 | 31.5 | ≤25 | 8-10 | 380 | 50.2 | |

Ф2200×7500 | 36 | ≤25 | 10-11 | 380 | 53.2 | |

Ф2200×8000 | 39 | ≤25 | 10-12 | 380 | 55 | |

Ф2200×9500 | 46 | ≤25 | 14-16 | 475 | 65 | |

Ф2400×11000 | 64 | ≤25 | 19-21 | 680 | 99.2 | |

Ф2400×13000 | 75.5 | ≤25 | 21-23 | 800 | 115.2 | |

Ф2600×13000 | 122 | ≤25 | 28-32 | 1000 | 148 | |

Ф3000×12000 | 109 | ≤25 | 32-35 | 1250 | 168.6 | |

Ф3000×13000 | 118 | ≤25 | 34-37 | 1400 | 172.3 | |

Ф3200×13000 | 185 | ≤25 | 45-50 | 1600 | 218 | |

Ф3800×13000 | 189 | ≤25 | 60-62 | 2500 | 286 | |

Ф4000×13000 | 231 | ≤25 | 85-87 | 3550 | 320 |

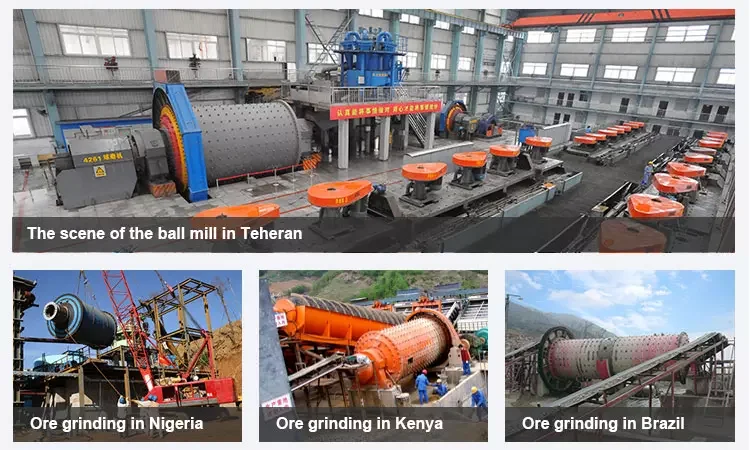

Application

Packing & Delivery

Company Profile

The Nile Machinery Co., Ltd. (referred to as THE NILE MACHINERY) was established in 1987 and is affiliated to the multinational corporation--The Nile Group. Its parent company is THE NILE CO., LTD located in Hong Kong.

The Nile Machinery is a comprehensive service enterprise that is mainly engaged in the production, processing, investment and product trade of mining equipment. Its business areas cover the metallurgy, mining, transportation, building materials, electricity, environmental protection, chemicals, new energy, agricultural products storage and processing industries.

THE NILE Factory

Our Advantages

Pre-sale services:

(1) Advice of model choice.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the

best processes and program

After-sale services :

(1) Arrange technicians to go to the site to guide installation

(2) If your machine is out of warranty period, you can go to the Nile's overseas office to buy spare parts.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site

production of 1 month, until the user' satisfaction.

(2) Design and manufacture machines according to customer's special requirements

(3) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the

best processes and program

After-sale services :

(1) Arrange technicians to go to the site to guide installation

(2) If your machine is out of warranty period, you can go to the Nile's overseas office to buy spare parts.

(4) complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site

production of 1 month, until the user' satisfaction.

FAQ

Q1: Are you factory or trade company?

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our

technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our

technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.