Industrial Weaving Crimped Wire Mesh Machine Manufacturing Machine for Small Business Stainless Steel Alloy Aluminum Weaving

US $7,350.00-7,750.00 / set

1 set(s)Minimum order

machine type:

weave wire mesh machine

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Engine, Gearbox, motor, Gear

wire diameter (mm):

0.7 - 4 mm

production capacity:

30sets/month

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| machine type | weave wire mesh machine |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Gearbox, motor, Gear |

| wire diameter (mm) | 0.7 - 4 mm |

| production capacity | 30sets/month |

| place of origin | Hebei, China |

| brand name | APM |

| model number | F102 |

| weight (kg) | 3500 |

| power (kw) | 2.2 |

| key selling points | Easy to Operate |

| warranty | 1 Year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Wire diameter | 0.7-2.0mm or 1.5-4.0mm |

| Opening | 1.5-15mm or 3-25mm |

| Weaving width | 1300mm,1600mm,2000mm&2500mm |

| Heddle Frame | 2pcs |

| Weft insertion | PLC control servo rapier |

| Weaving speed | 30-40 times/minute,15-30times/min,15-20times/min |

| Motor Power | 2.2KW 4KW 3.0KW 5.5KW |

| Voltage | 380V/220V |

Product Detail

Full automatic crimped wire mesh machine with the PLC Rapier. The APM-AM-F102 crimped wire mesh weaving machine is for wire diameter from 0.7mm to 2.0mm or 1.5-4mm pulling weft wire by one servo motor with reducers.

This looms can only weave square & rectangular meshes because the slay is moved by a steady stroke crankshaft at the speed 50-60times/minute by frequency control. Thus the front screen clamp beam’s position must be adjusted by hand as per mesh/wire ratios.

This looms can only weave square & rectangular meshes because the slay is moved by a steady stroke crankshaft at the speed 50-60times/minute by frequency control. Thus the front screen clamp beam’s position must be adjusted by hand as per mesh/wire ratios.

Machine Type | APM-AM-F102 |

Weaving Width | 1300mm, 1600mm, 2000&2500mm |

Wire diameter | 0.7-2mm or 1.5-4mm |

Opening size | 1.5-15mm or 3-25mm |

Heddle Frame | 2pcs |

Shedding Mechanism | Aluminum heddle frame, 1.5KW AC Servo per frame |

Weft Insertion | PLC control servo rapier |

1.How about your machine’s working speed and output?

A:Please contact our professional salesman, you can get all the details.

2.How to learn the operation of your machine?

A: 1) We can send our engineer to your factory for training

2) You can send your machine operator to our factory

3) We can send you a video for learning

3.If the parts was broken, how about the solution?

A: 1)Non-artificial damage parts, within warranty period, can be provided free of charge

2)Custom-made parts with detailed drawing can be provided

4. Are you trading company or manufacturer ?

A: We are factory.

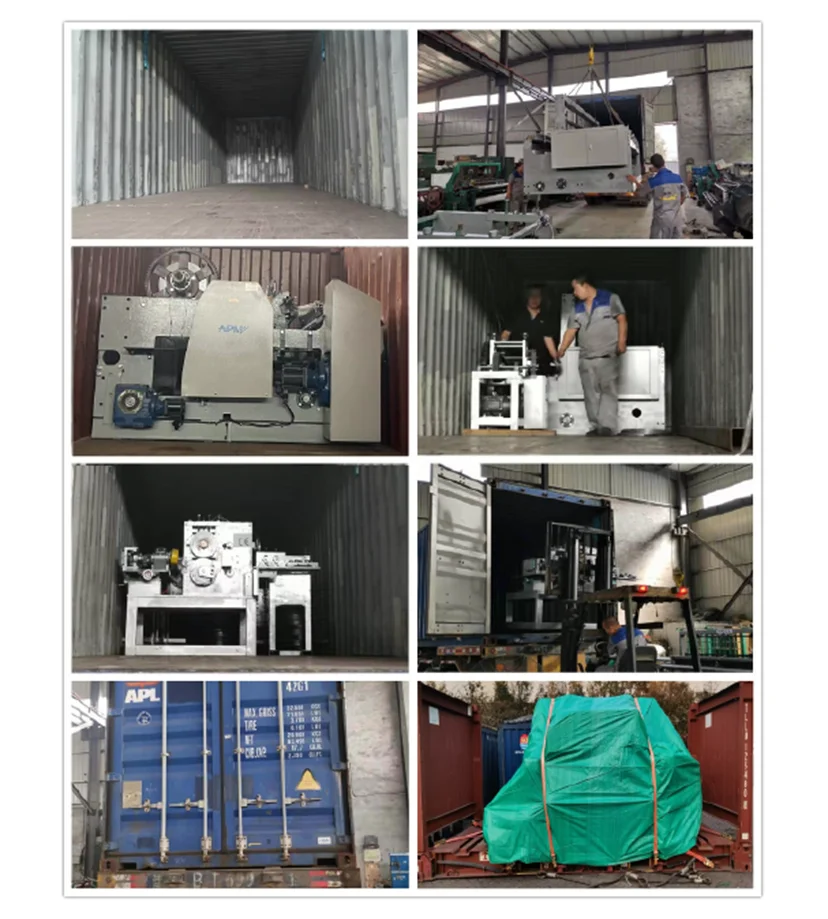

5. How long is your delivery time?

A: Generally it is 30-45 days. It is according to quantity.

6. Do you provide samples ? is it free or extra ?

A: No, we couldn't offer the sample for free charge but we can provide video

7. What is your terms of payment ?

A: Paymen 50% T/T in advance ,balance before shipment.

A:Please contact our professional salesman, you can get all the details.

2.How to learn the operation of your machine?

A: 1) We can send our engineer to your factory for training

2) You can send your machine operator to our factory

3) We can send you a video for learning

3.If the parts was broken, how about the solution?

A: 1)Non-artificial damage parts, within warranty period, can be provided free of charge

2)Custom-made parts with detailed drawing can be provided

4. Are you trading company or manufacturer ?

A: We are factory.

5. How long is your delivery time?

A: Generally it is 30-45 days. It is according to quantity.

6. Do you provide samples ? is it free or extra ?

A: No, we couldn't offer the sample for free charge but we can provide video

7. What is your terms of payment ?

A: Paymen 50% T/T in advance ,balance before shipment.