China Tencan Efficiency Vertical Attrition Mill with High Speed and Low Noise Ball Mill Chocolate Machine

1 set(s)Minimum order

output (kg/h):

0.1 - 0.7 kg/h

feeding size (mm):

0.1 - 10 mm

output size (mesh):

4500 - 12500 mesh

power (kw):

0.37

range of spindle speed(r.p.m):

50 - 1400 r.p.m

application:

Chemicals Processing

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| output (kg/h) | 0.1 - 0.7 kg/h |

|---|---|

| feeding size (mm) | 0.1 - 10 mm |

| output size (mesh) | 4500 - 12500 mesh |

| power (kw) | 0.37 |

| range of spindle speed(r.p.m) | 50 - 1400 r.p.m |

| application | Chemicals Processing |

| type | Ball Mill |

| Product Type | vertical attrition mill |

| place of origin | Hunan, China |

| brand name | TENCAN |

| voltage | 220V,380V |

| dimension(l*w*h) | 1188*550*1175mm |

| weight (kg) | 29 KG |

| warranty | 1 year |

| key selling points | Automatic |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | Gear, motor, Other, PLC |

| Product name | Turmeric Grinder Machine |

| Brand | Tencan |

| Rotating speed | 50-1400r/min,adjustable |

| Power | 0.37kw |

| Output granularity | 400-12500mesh |

| Milling Mode | dry or wet milling |

| Volume of grinding jar | 0.5,1,2,3L |

| Feeding particle size | soft<10mm, other<3mm |

| Condition | New |

| Applicable Industries | Food & Beverage Factory, Energy & Mining, Other |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

Product Detail

Recommend Products

Products Description

China Tencan Efficiency Vertical Attrition Mill with High Speed and Low Noise Ball Mill Chocolate Machine

Model NO. | Rotate Speed (rpm) | Volume (L) | Load Capacity (L) | Power Supply (KW/V) | Available Jars | Feed Size (mm) | Output Granularity (μm) | Speed Control Mode | Catagory |

JM-1L | 50-1400 | 1 | 0.35 | 0.37KW/220V | Stainless Steel Nylon Alumina Ceramic PU Zirconia Agate PTFE | ≤5 | ≤1μm | Frequency speed adjuster | Laboratory Scale |

JM-2L | 50-1400 | 2 | 0.7 | 0.37KW/220V | ≤5 | ≤1μm | |||

JM-3L | 50-1400 | 3 | 1.05 | 0.37KW/220V | ≤5 | ≤1μm | |||

JM-5L | 60-600 | 5 | 1.75 | 0.75KW/220V | ≤5 | ≤1μm | Frequency speed adjuster or Fixed speed setting For buyer’s option | ||

JM-10L | 60-560 | 10 | 3.5 | 1.5KW/220V | ≤10 | ≤1μm | Light Type Scale | ||

JM-15L | 60-380 | 15 | 5.25 | 2.2KW/380V | ≤10 | ≤1μm | |||

JM-20L | 60-380 | 20 | 7 | 2.2KW/380V | ≤10 | ≤1μm | |||

JM-30L | 60-310 | 30 | 10.5 | 3KW/380V | Carbon Steel Stainless Steel Nylon liner PU liner Alumina Ceramic Liner PTFE liner | ≤10 | ≤1μm | ||

JM-50L | 60-140 | 50 | 17.5 | 4KW/380V | ≤10 | ≤1μm | |||

JM-100L | 60-140 | 100 | 35 | 7.5KW/380V | ≤20 | ≤1μm | Production Type Scale | ||

JM-200L | 60-140 | 200 | 70 | 11KW/380V | ≤20 | ≤1μm | |||

JM-300L | 60-110 | 300 | 100 | 15KW/380V | ≤20 | ≤1μm | |||

JM-500L | 60-90 | 500 | 170 | 18.5KW/380V | ≤20 | ≤1μm | |||

JM-600L | 60-90 | 600 | 210 | 22KW/380V | ≤20 | ≤1μm |

Stirred ball mill mainly consists of jar with inner grinding media, stirring device and other auxiliary devices such as recycling device, cooling device, timing device, speed adjusting controller, and etc. Its advantages of high efficiency and fine granularity meet technological requirements of various processes. Stirred ball mill is a kind of ideal equipment that are used to crush new materials and research painting for universities, research centers and enterprises because of its features of small batch, low power and low price.

Working Principle of Stirred Ball Mill

When machine rotates with high speed under driving of main axis and grind media move irregularly at the same time, the grind material can be crushed, ground and sheared into fine granularity powder. The size, shape and matching ratio of the grind media can affect the grinding result. Generally speaking, the bigger the mill media is, the finer the grinding powder is. A proper match ratio of grind medias and proper adjustment of rotation speed can get better grinding effect.

Applications of Stirred Ball Mill

Light type stirred ball mill is widely applied in fields of zirconia silicate, zirconia, alumina oxide, ceramic, chemical,

electronic material, magnetic material, paper-making, painting, non-metal minerals, new materials, coating, graphite, calcium carbonate and so on.

Features of Stirred Ball Mill

1. High utilization rate of energy, saving energy.

2. Granularity is adjustable by adjusting grinding time.

3. Less vibration, low noise.

4. Simple structure, easy operation.

5. Meet requirements of various processes, realize continuous or intermittent production

6. Jar with jacket, easy to control the grinding temperature

7. Customized service is available. Special functions such as timing, speed adjusting, recycling, temperature controlling can be selected and ordered.

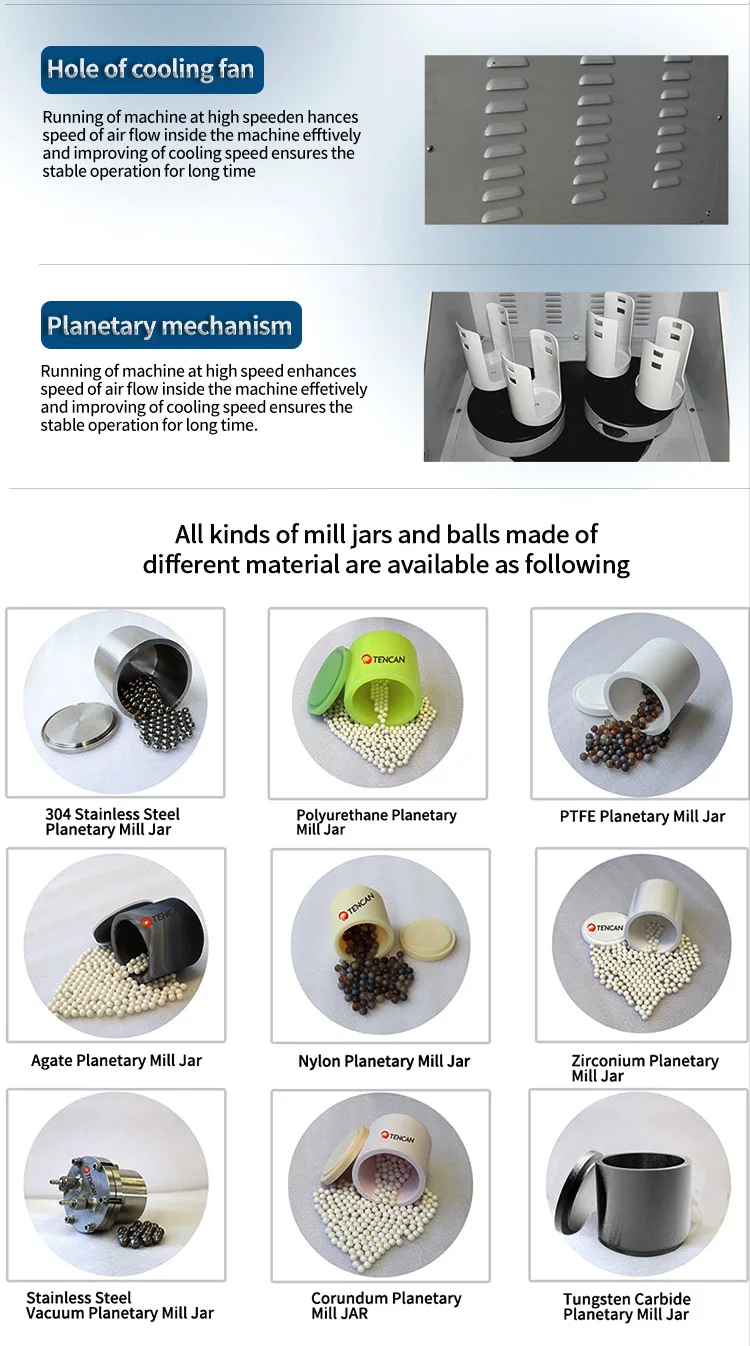

8. A variety of grinding jars in different materials is available for customer’s option such as stainless steel, corundum ceramic, polyurethane, zirconia and so on.

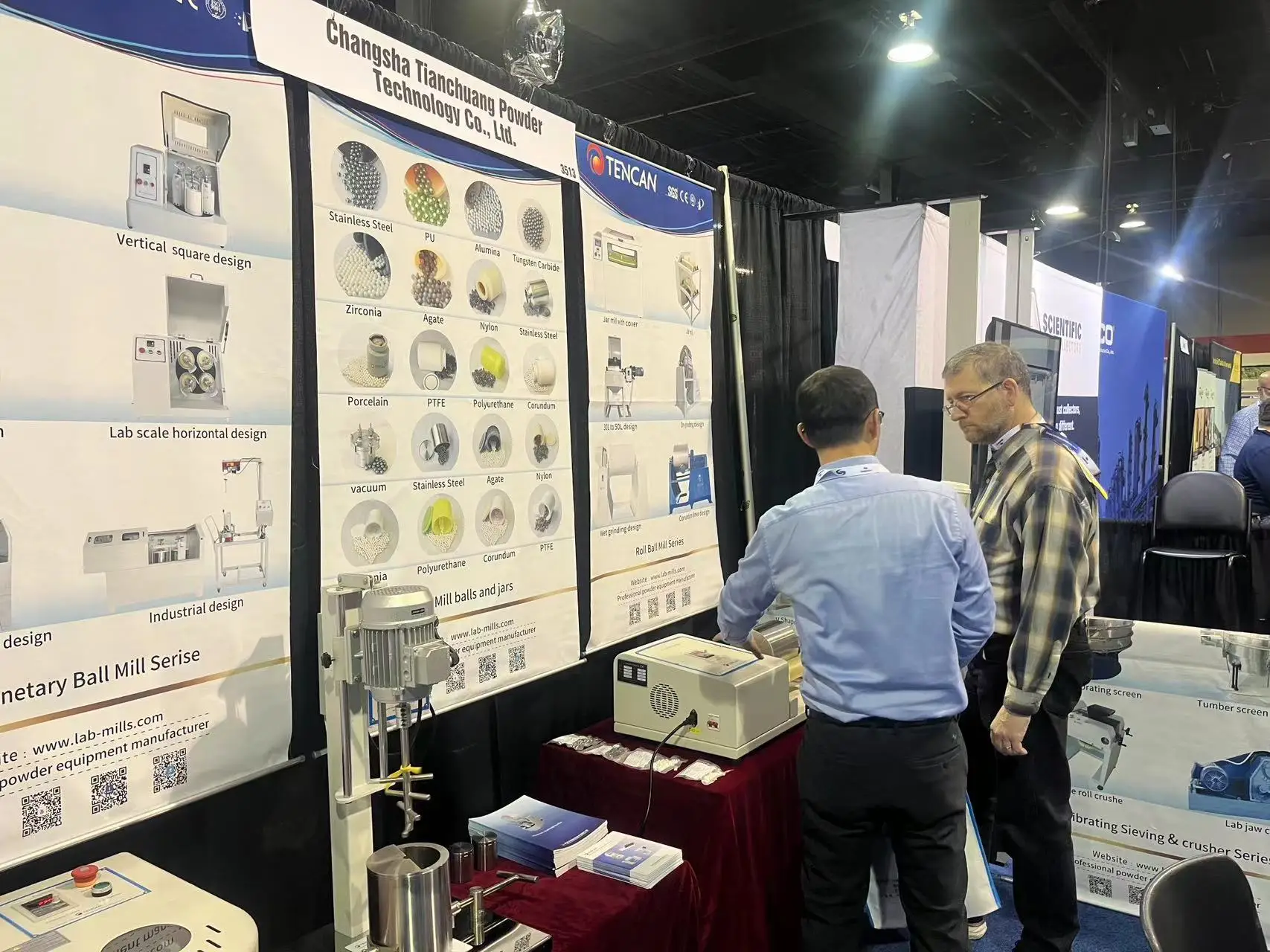

Company Profile

Changsha Tencan Powder Technology Co.,ltd is founded in 2006. It is located in Xingsha Town, Changsha City of Hunan Province, China.

Our factory is a supplier of manufacturing planetary ball mill, roll ball mil, stirring machine, mixer machine, vibration

ball mill, vacuum glove box, mill tank, ball media.. Harvard University, Peking University, Tsingha University, Foxconn, BYD, CASC etc are our regular customers, giving high praise for our machines for their long using life with less mechanical failure.

With the sustained business conception of "credit is the basis, quality is the first", we gain the high trust from customers. A

first-class enterprises goal ----- brand, do first-class enterprises, and take Group operations, to the international development.

Certifications

Communication with Customers

FAQ

1. Are you manufacturer or trade company?

We are one of leading manufacturers in China, which focuses on designing, manufacturing and selling all kinds of powder grinding equipment including planetary ball mills, roll ball mills, stir ball mills, crushers, mixers and sieve shakers as well as accessories matched with machines.

2. What is your delivery time if I place an order?

We often have a great deal of regular machine models and accessories in stock available. If you want to order our regular items, it takes about 1-3 working days to finish packing and inspection, Generally speaking we can make shipment of regular order from our warehouse within 3-7 working days after payment is received.

3. What questions about requirements are required to provide to us if you inquiry about ball mills?

Answers:

* What material is needed to be grind? By wet or dry method?

* How many liters of material are required to be ground per batch?

* What is feed size (mm) of starting materials?

* What final particle size (μm or nm or meshes) is required by grinding?

* Is material allowed with metal impurity contamination while grinding?

4. Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.

Delivery address of material sample:

Changsha Tianchuang Powder Technology Co., Ltd

Room 804, 2nd Building, No.68 Luositang Road, Changsha Economic and Technological Development Zone, Changsha, Hunan, China 410100

Contact Name: Aivin Ai Mobile Phone: +86 13548659522

5. What’s your warranty?

One-year warranty period is provided. If any problem while you are using the machine, you can send Email to: service@lab-mills.com for after-sale services.

6. What is MOQ (Minimum Order Quantity) of one order?

One set of machine or one piece of accessories (like ball mill jar and balls) are acceptable.

We are one of leading manufacturers in China, which focuses on designing, manufacturing and selling all kinds of powder grinding equipment including planetary ball mills, roll ball mills, stir ball mills, crushers, mixers and sieve shakers as well as accessories matched with machines.

2. What is your delivery time if I place an order?

We often have a great deal of regular machine models and accessories in stock available. If you want to order our regular items, it takes about 1-3 working days to finish packing and inspection, Generally speaking we can make shipment of regular order from our warehouse within 3-7 working days after payment is received.

3. What questions about requirements are required to provide to us if you inquiry about ball mills?

Answers:

* What material is needed to be grind? By wet or dry method?

* How many liters of material are required to be ground per batch?

* What is feed size (mm) of starting materials?

* What final particle size (μm or nm or meshes) is required by grinding?

* Is material allowed with metal impurity contamination while grinding?

4. Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.

Delivery address of material sample:

Changsha Tianchuang Powder Technology Co., Ltd

Room 804, 2nd Building, No.68 Luositang Road, Changsha Economic and Technological Development Zone, Changsha, Hunan, China 410100

Contact Name: Aivin Ai Mobile Phone: +86 13548659522

5. What’s your warranty?

One-year warranty period is provided. If any problem while you are using the machine, you can send Email to: service@lab-mills.com for after-sale services.

6. What is MOQ (Minimum Order Quantity) of one order?

One set of machine or one piece of accessories (like ball mill jar and balls) are acceptable.