CNC Custom Spare Parts for RC Car Remote Control Car Customized Auto Aerospace Components OEM CNC Machining

1 piece(s)Minimum order

CNC Machining or Not:

Cnc Machining

Type:

Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Material Capabilities:

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not:

Micro Machining

Place of Origin:

China

Model Number:

SZJC

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| CNC Machining or Not | Cnc Machining |

|---|---|

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Micro Machining or Not | Micro Machining |

| Place of Origin | China |

| Model Number | SZJC |

| Brand Name | OEM |

| Shape model | CNC machining parts |

| Material | Plastic,stainless steel,aluminium,brass |

| Method | CNC machining |

| Surface treatment | Smooth,sandblasting,anodizing,electroplating,zinc plating are okay |

| Tolerance | + - 0.005 mm |

| MOQ | 1 |

| Drawing Format | PDF/DWG/IGS/STP/ etc |

| Our Service | OEM&ODM CNC machining,as per customer's requirement |

| Equipment | CNC Machining Center,CNC lathe,CNC turning,milling |

| Delivery | By DHL,FEDEX,Shipping,cars |

Product Detail

Specification

CNC Custom Spare Parts for RC Car Remote Control Car Customized Auto Aerospace Components OEM CNC Machining

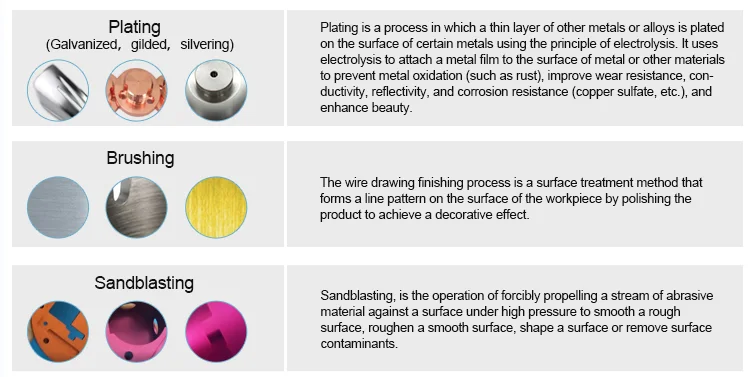

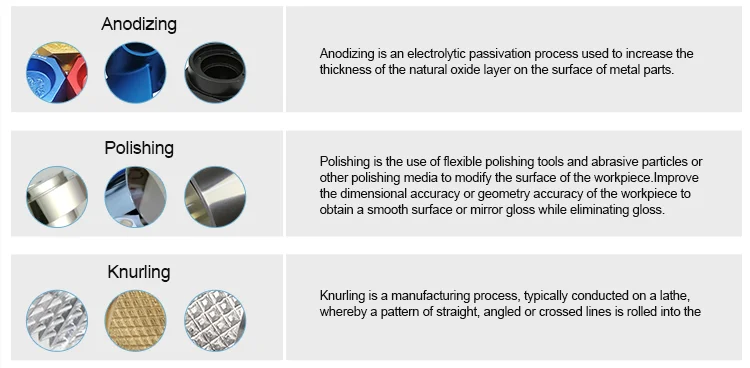

Surface treatment | Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling, or customer's requirements |

Material Capacities | Metal: Aluminum alloy, stainless steel, brass, copper, tool steel, carbon steel, iron, Plastic: ABS, POM, PC(Poly Carbonate), PC+GF, PA(nylon), PA+GF, PMMA(acrylic), PEEK, PEI ,etc |

CNC processing scope | CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC Lathe, High precision 5-Axis turning-milling combined machining |

Application | Optical instrument, Automotive, Electronic device, Digital communication, UAV, Aerospace, Bicycle, Pneumatic tools, Hydraulic, Automatic Mechanical, etc |

Drawing Format | IGS, STP, X_T, DXF, DWG, Pro/E, PDF, PNG, JPG |

Delivery | DHL, FedEx, EMS, UPS, or customer's requirements |

Package | Tissue paper, EPE, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer requirements |

OUR SERVICES

CNC Turning

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes material from a rotating rigid material. This process produces different shapes and sizes depending on the turning operations used.

CNC Milling

It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece into a finished product.

CNC Drilling

CNC drilling is a machining process involving rotating cutting tools for producing round holes in a stationary workpiece. The purposes of drilling are aesthetic ones or for further accommodating of screws and bolts.

Material Available | ||||||||

Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc | |||||||

Stainless Steel | 303, 304, 304L, 316, 316L, 410, 420, 430, etc | |||||||

Steel | Mild Steel, Carbon Steel, 1018, 1035, 1045, 4140, 4340, 8620, XC38, XC48, E52100, Q235, SKD11, 35MF6Pb, 1214, 1215, etc | |||||||

Iron | A36,45#, 1213, etc | |||||||

Brass | HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, etc | |||||||

Copper | C11000, C12000, C22000, C26000, C28000, C36000 | |||||||

Titanium Alloy | TC1, TC2, TC3,TC4, etc | |||||||

Plastic | ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc | |||||||

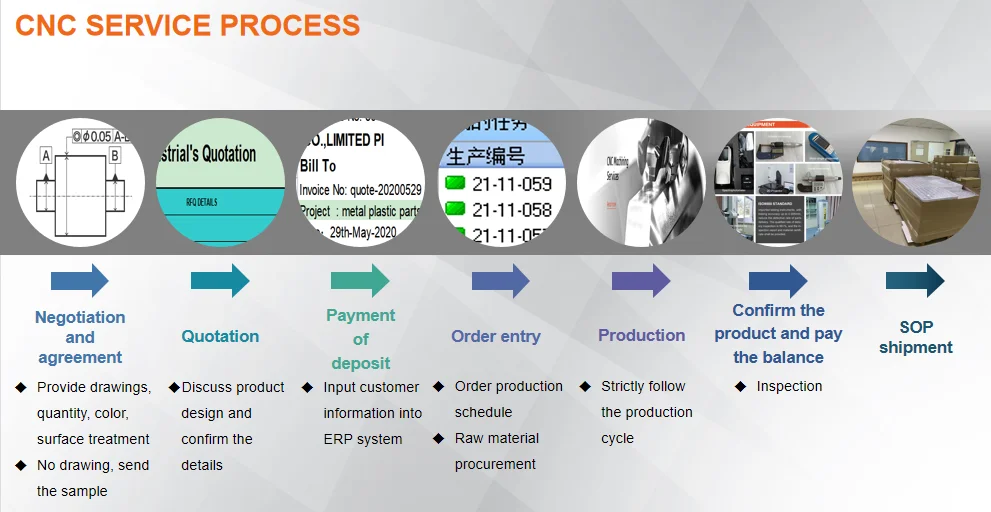

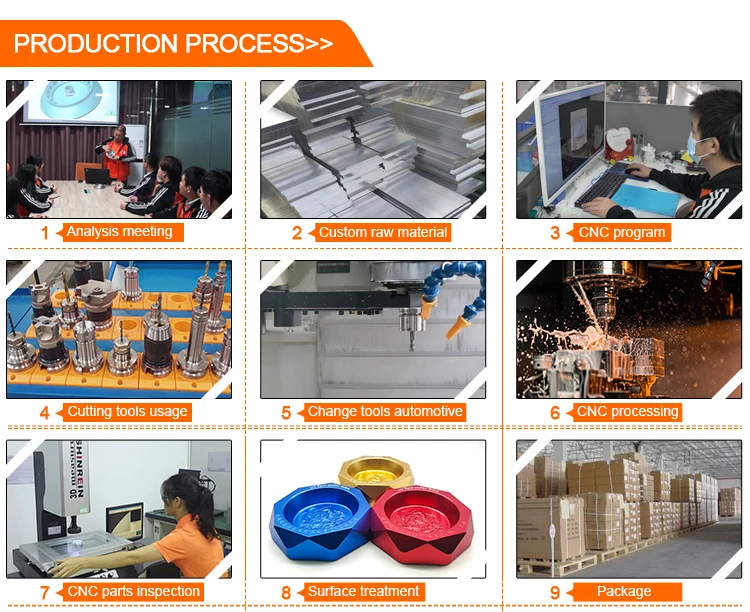

Production Process

Surface Treatment

Company Profile

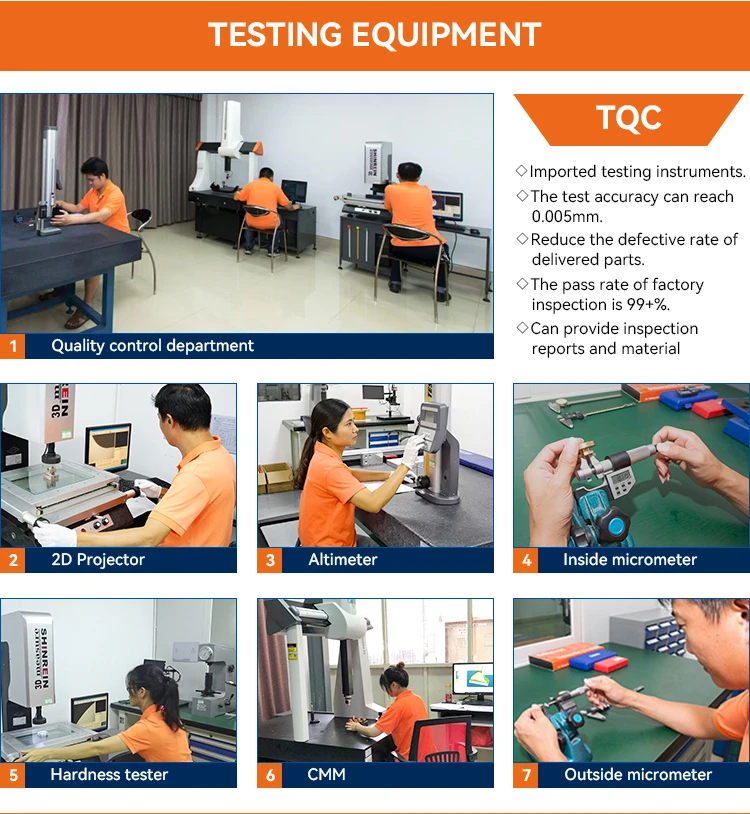

Quality Control Standards

In order to live up to the trust of our customers, quality control and assurance is achieved through:

1. Comprehensive written procedures and policies;

2. Details records of incoming raw material;

3. Analysis of root cause of non-conformances

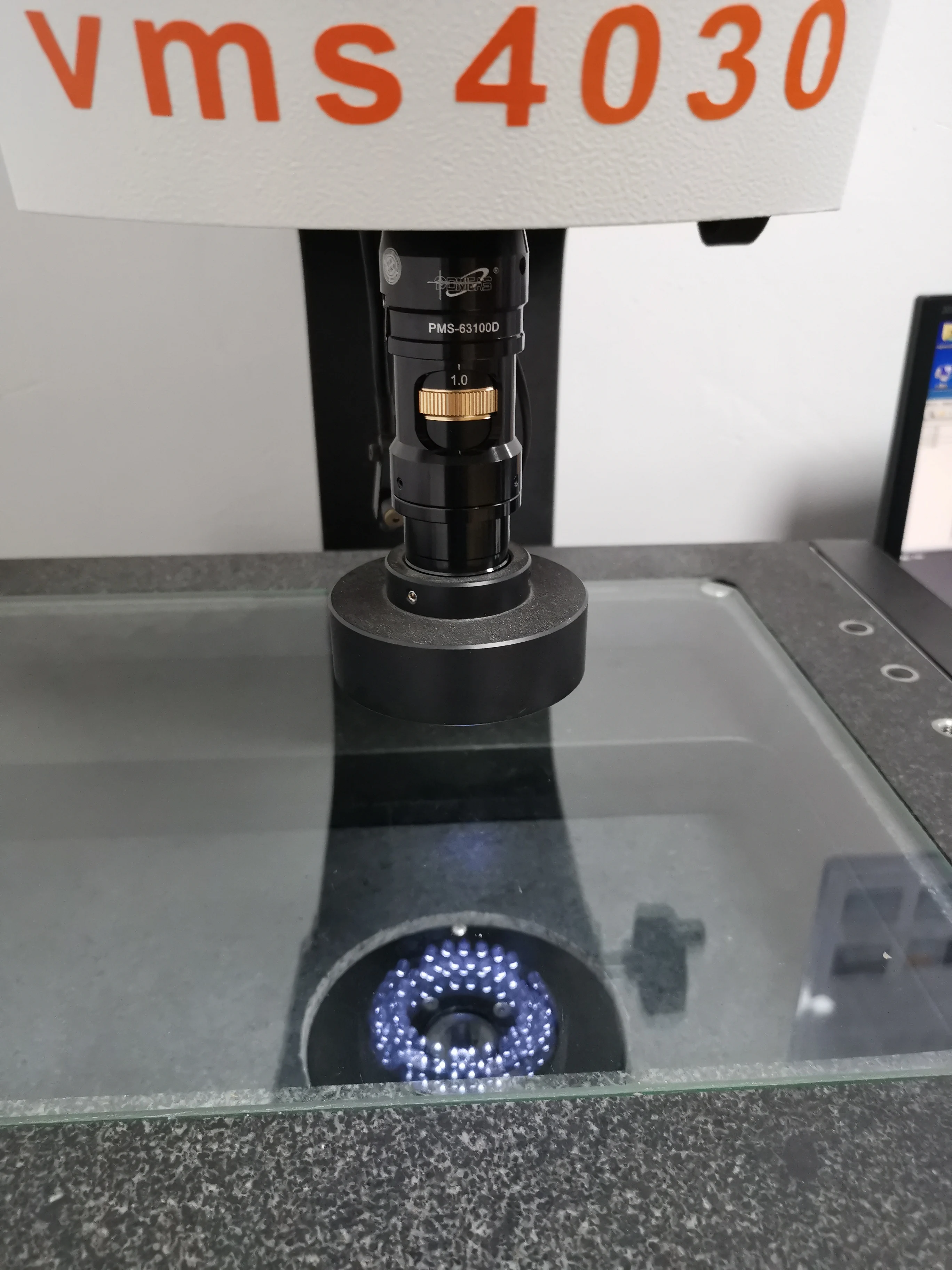

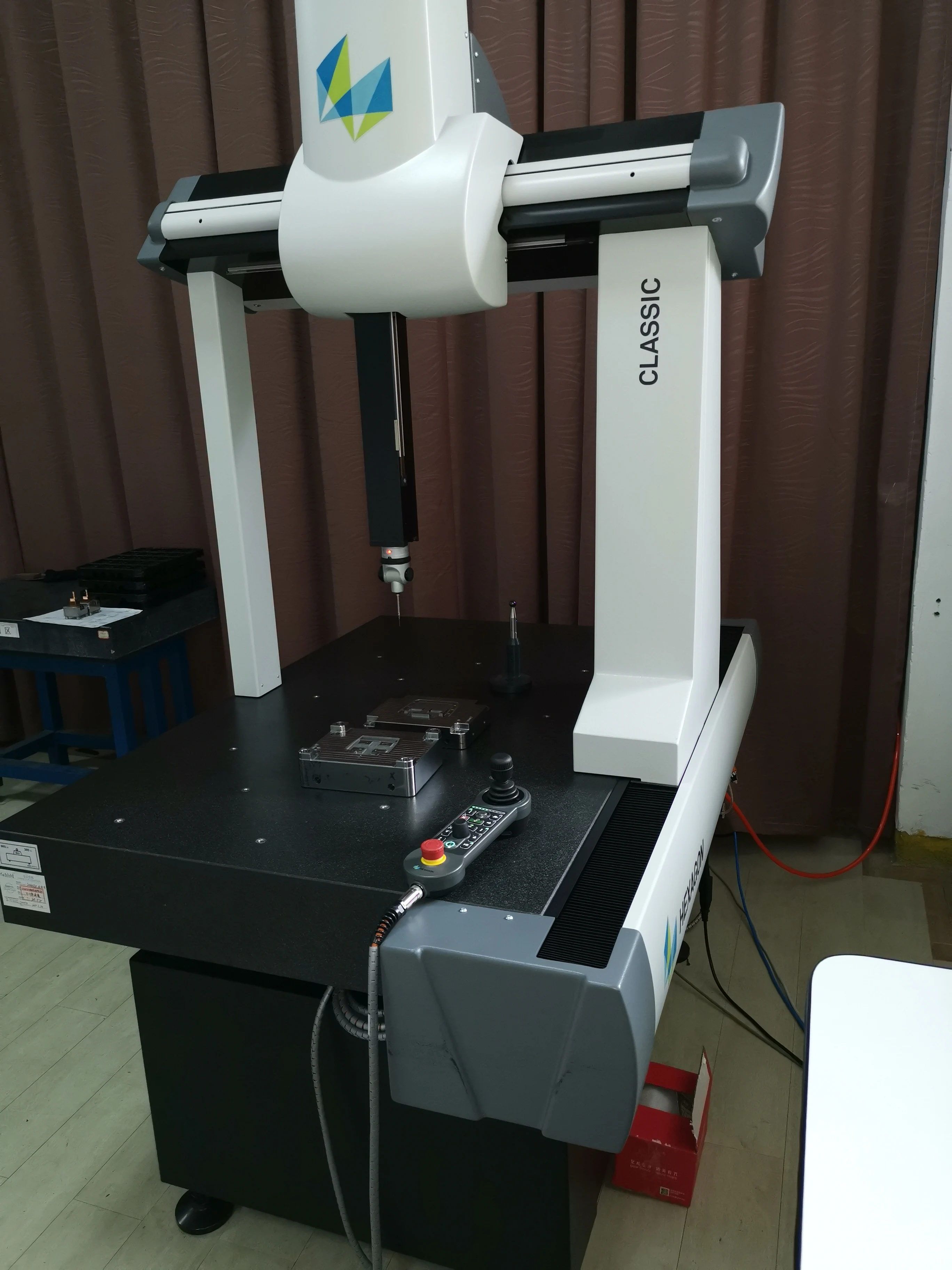

4. Fully equipped inspection department;

5. Consistent calibration and labeling of inspection tools

FAQ

Q1 : Do you customize products according to our design drawings ?

A1 : Yes, we are a professional metal manufacturing factory with experienced engineering team, which can make customized products according to customer drawings.

Q2 : Will my design drawings be safe when you get it ?

A2 : Yes, we will not publish your design to a third party unless your permission is obtained. We can sign NDA before you send the drawings.

Q3 : Does the company have the capacity for mass production?

A3 : The company has independent production and large-scale production conditions, one-stop service,70 CNC machine tools,40 injection molding machines, and has its own mold workshop.

Q4 : How to deal with surface treatment problems?

A4 : Sample color identification and dispensing ensure batch color consistency, strengthen manual inspection, avoid the defective products.

Q5 : How to avoid mass order quality problems?

A5 : Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as the key point of quality control, follow up the inspection and defense throughout the process.