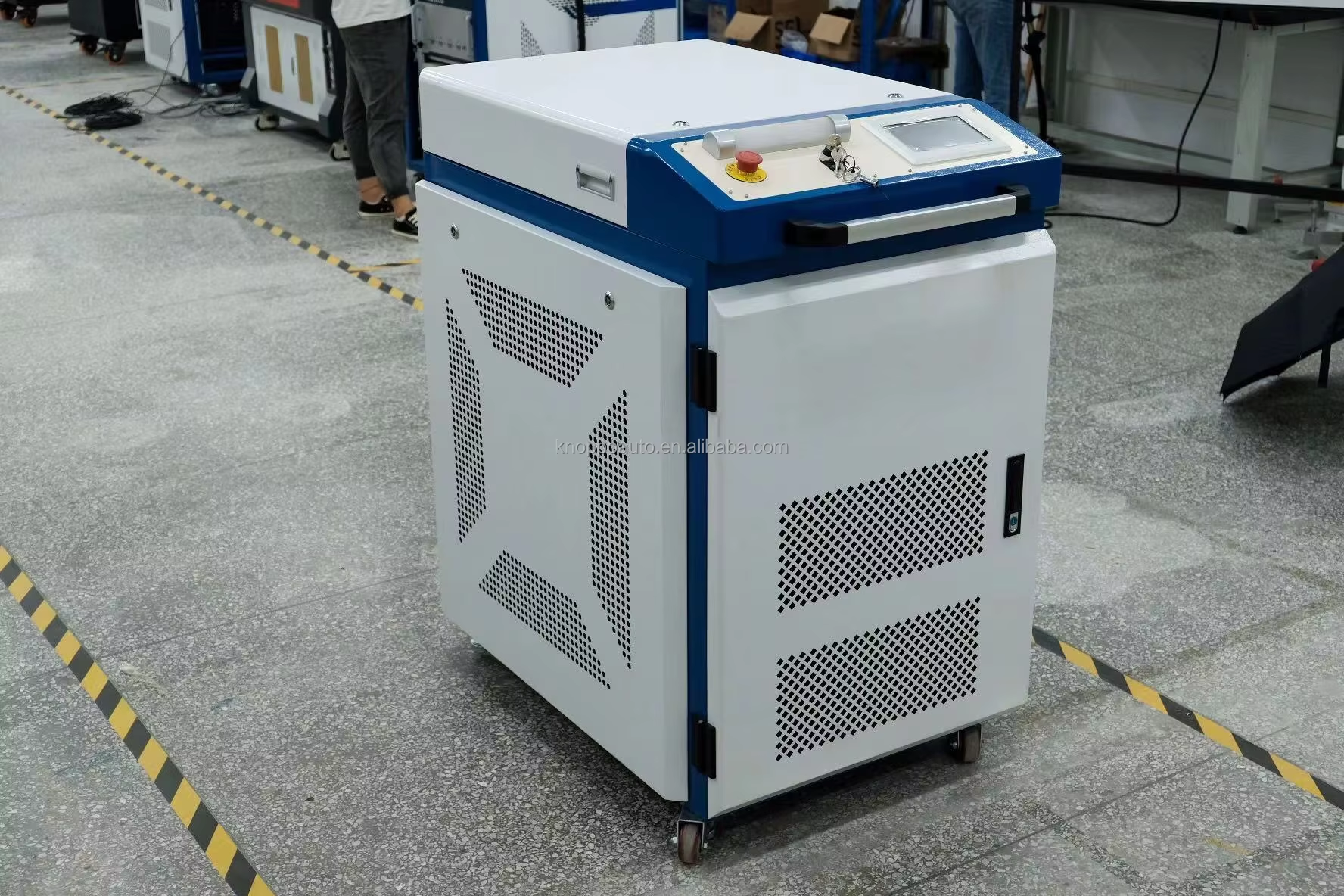

Continuous Laser 1000W 2000W 3000W Paint and Rust Removing Handheld Fiber Laser Cleaning Machine

US $3,300.00 / set

1 set(s)Minimum order

condition:

New

power(w):

3000W, 1500W, 1000W, 2000W

applicable material:

Stainless Steel, Carbon steel, Aluminum, Wood, Stone, metal, Rubber

laser type:

Fiber Laser

place of origin:

China

brand name:

KNOPPO

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| condition | New |

|---|---|

| power(w) | 3000W, 1500W, 1000W, 2000W |

| applicable material | Stainless Steel, Carbon steel, Aluminum, Wood, Stone, metal, Rubber |

| laser type | Fiber Laser |

| place of origin | China |

| brand name | KNOPPO |

| dimension(l*w*h) | 760mmX780X790mm |

| laser source brand | Raycus |

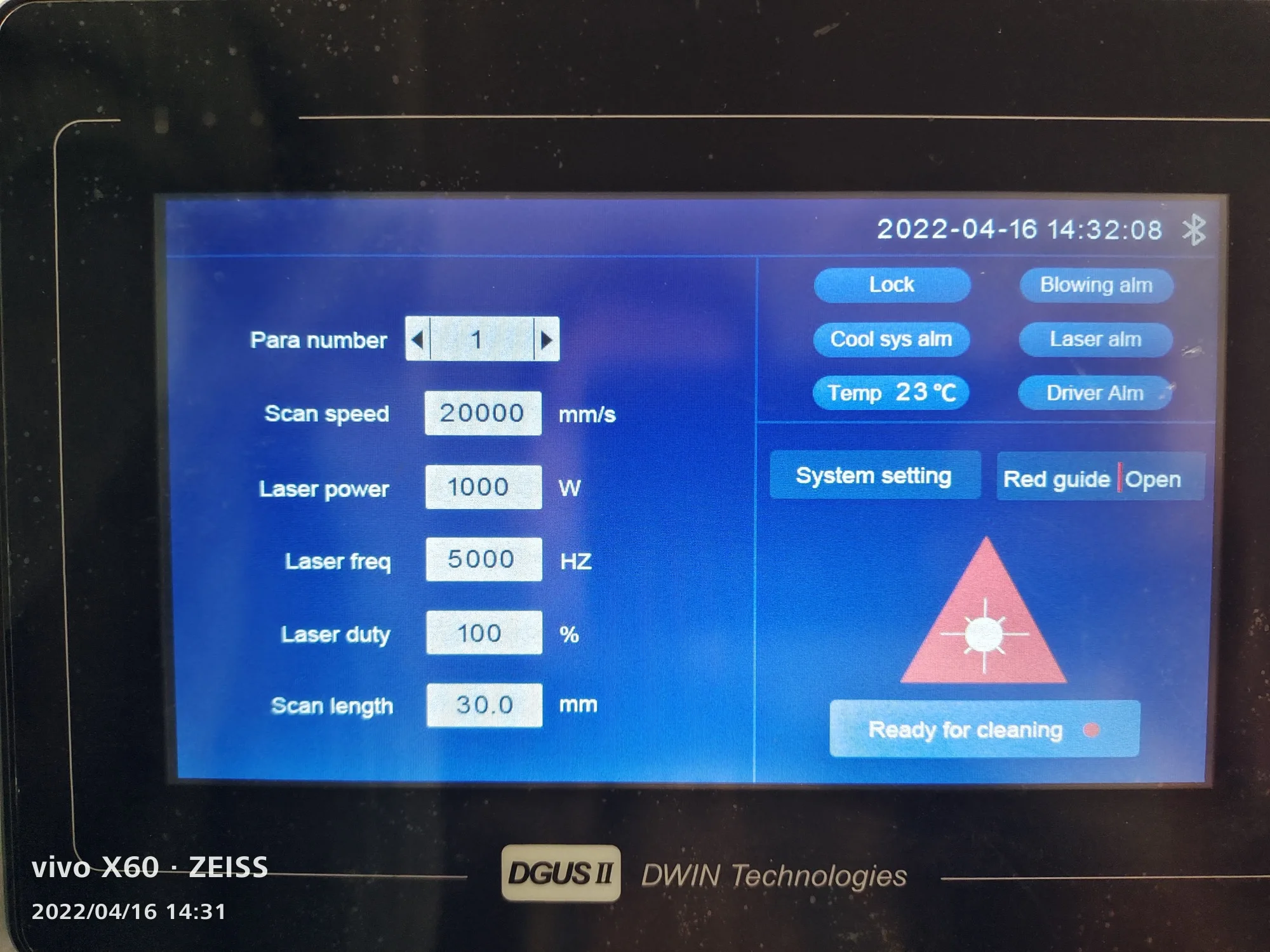

| laser head brand | DWIN |

| guiderail brand | HIWIN |

| control system brand | DWIN |

| weight (kg) | 150 KG |

| key selling points | Easy to Operate |

| warranty | 3 years |

| Model | KC-M |

| Laser Power | 1000W 1500W 2000W 3000W |

| Laser source | Raycus/ MAX/JPT |

| Cleaning efficiency | 12 m3/h |

| Scan width | 10~150mm |

| Cleaning gun | Relfar |

| Cooling Type | Water cooling |

| Voltage | 220V/380V,50HZ/60HZ |

| Cleaning Materials | Metal Rust Oil Dust Coating |

| Cleaning Process | Non-contact Laser Cleaning |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 3 years |

| Applicable Industries | Printing Shops, Manufacturing Plant, Construction works , Machinery Repair Shops, Advertising Company, Energy & Mining, Building Material Shops |

| Local Service Location | United Kingdom, Germany |

| Showroom Location | United Kingdom, Germany |

| Core Components | PLC, Laser Source |

| Year | 2023 |

| After-sales Service Provided | 3 Years Warranty |

Product Detail

3000W 2000W 1500W 1000W Fiber Laser Cleaning Machine For High-efficiency Laser Rust and Oil Removal

Product Description

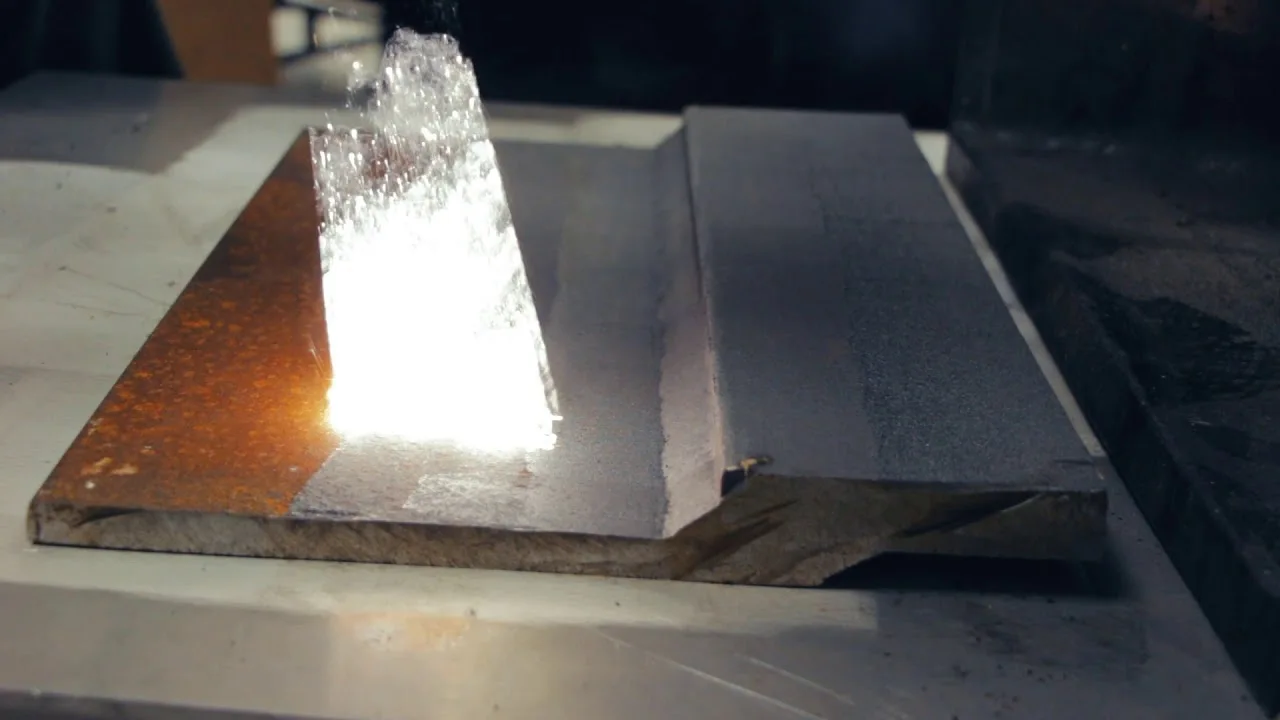

Application

Metalsurface rust removal, Surfacepaint removal and paint treatment, Surfaceoil, stains, dirt cleaning, Surfacecoating, clear coating, Weldingsurface / spray surface pretreatment, Stonesurface dust and attachment removal, Rubbermold residue cleaning.

A Metal surface cleaning

B Removal paint of metal surface

C stains cleaning on the surface

D Surface coating cleaning

E Pre-treatment of welding surface cleaning

F Stone surface cleaning

G Rubber mold residue cleaning

A Metal surface cleaning

B Removal paint of metal surface

C stains cleaning on the surface

D Surface coating cleaning

E Pre-treatment of welding surface cleaning

F Stone surface cleaning

G Rubber mold residue cleaning

Advantages

1.non-contact cleaning, does not damage the part substrate.

2.precise cleaning, can achieve precise location, the exact size of the selective cleaning.

3.laser-cleaning-machine without any chemical cleaning fluid, no supplies, safety and environmental protection.

4.simple operation, power can be hand-held or with the robot to achieve automated cleaning.

5.cleaning efficiency is very high, save time.

6.laser cleaning system is stable, almost no maintenance.

2.precise cleaning, can achieve precise location, the exact size of the selective cleaning.

3.laser-cleaning-machine without any chemical cleaning fluid, no supplies, safety and environmental protection.

4.simple operation, power can be hand-held or with the robot to achieve automated cleaning.

5.cleaning efficiency is very high, save time.

6.laser cleaning system is stable, almost no maintenance.

Technical Parameter | ||||||||

Laser source | Raycus fiber laser | |||||||

Laser power | 1000W/1500W/2000W/3000W | |||||||

Power range (%) | 10-100(adjustment ) | |||||||

Repeat frequency (KHz) | 10-50(adjustment) | |||||||

Cleaning efficiency (m2/h) | 12 | |||||||

Focal length (mm) | 210/160 changeable | |||||||

Cooling mode | Water cooling | |||||||

Size | 1100mm×700mm×1150mm | |||||||

Weight | 170Kg | |||||||

Scanning width | 10-150mm | |||||||

Mobile mode | Handheld | |||||||

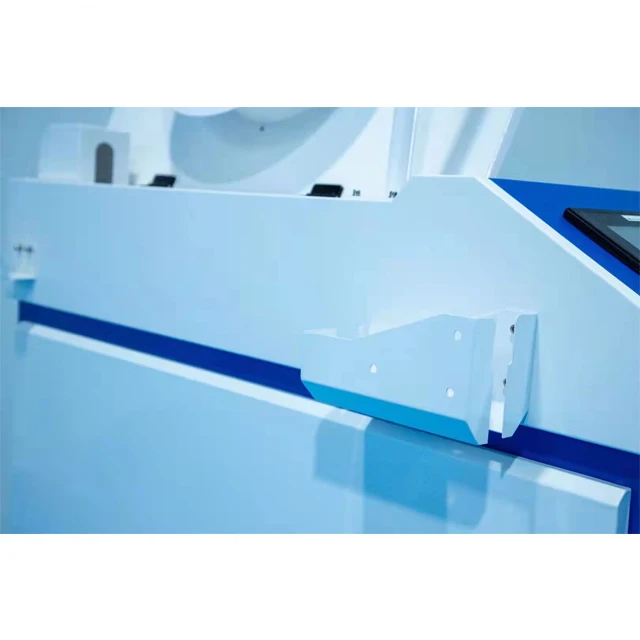

Detailed Images

Configuration

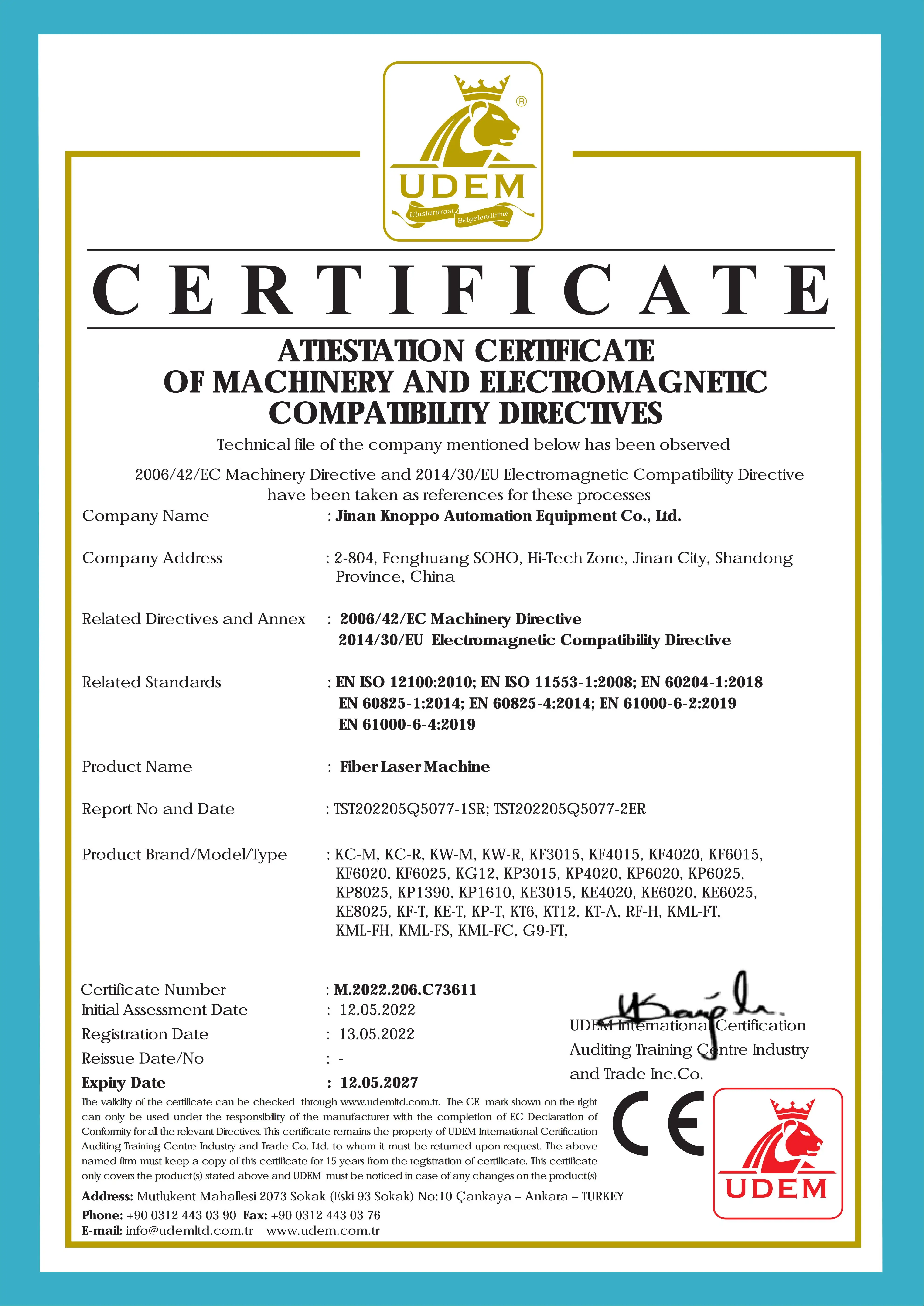

European CE Certificated

All model passed European CE standard

Related Products

Packing&Shipping

Wooden Box Package

After Sales Service

1.24-hour full after sales service.

2.All finished machine we delivered are 100% strictly tested by our QC department and engineering department.

3.OEM Service Customized and OEM orders are welcome due to our abundant experiences. All the OEM services are free.

2.All finished machine we delivered are 100% strictly tested by our QC department and engineering department.

3.OEM Service Customized and OEM orders are welcome due to our abundant experiences. All the OEM services are free.

Company Introduction

Knoppo Automation is one of the world’s leading manufacturers of high-tech industrial laser solutions, dedicated to providing laser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient and competitive. With more than 15,000 laser cutting systems in the market and a rapidly increasing global base, Knoppo Automation is in a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times in already more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, all of which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmental friendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions for Industry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tube cutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled and experienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

Contact Us