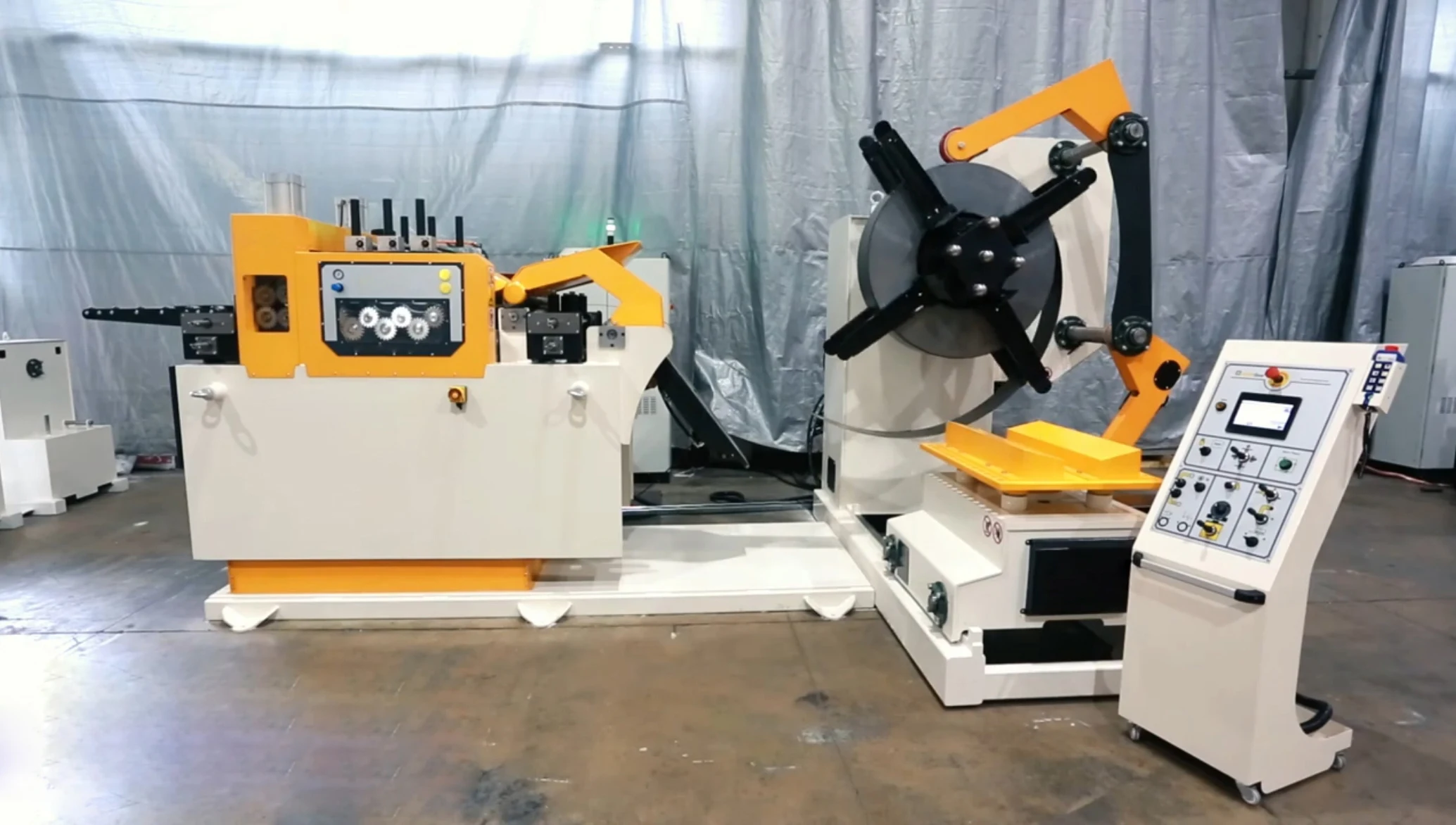

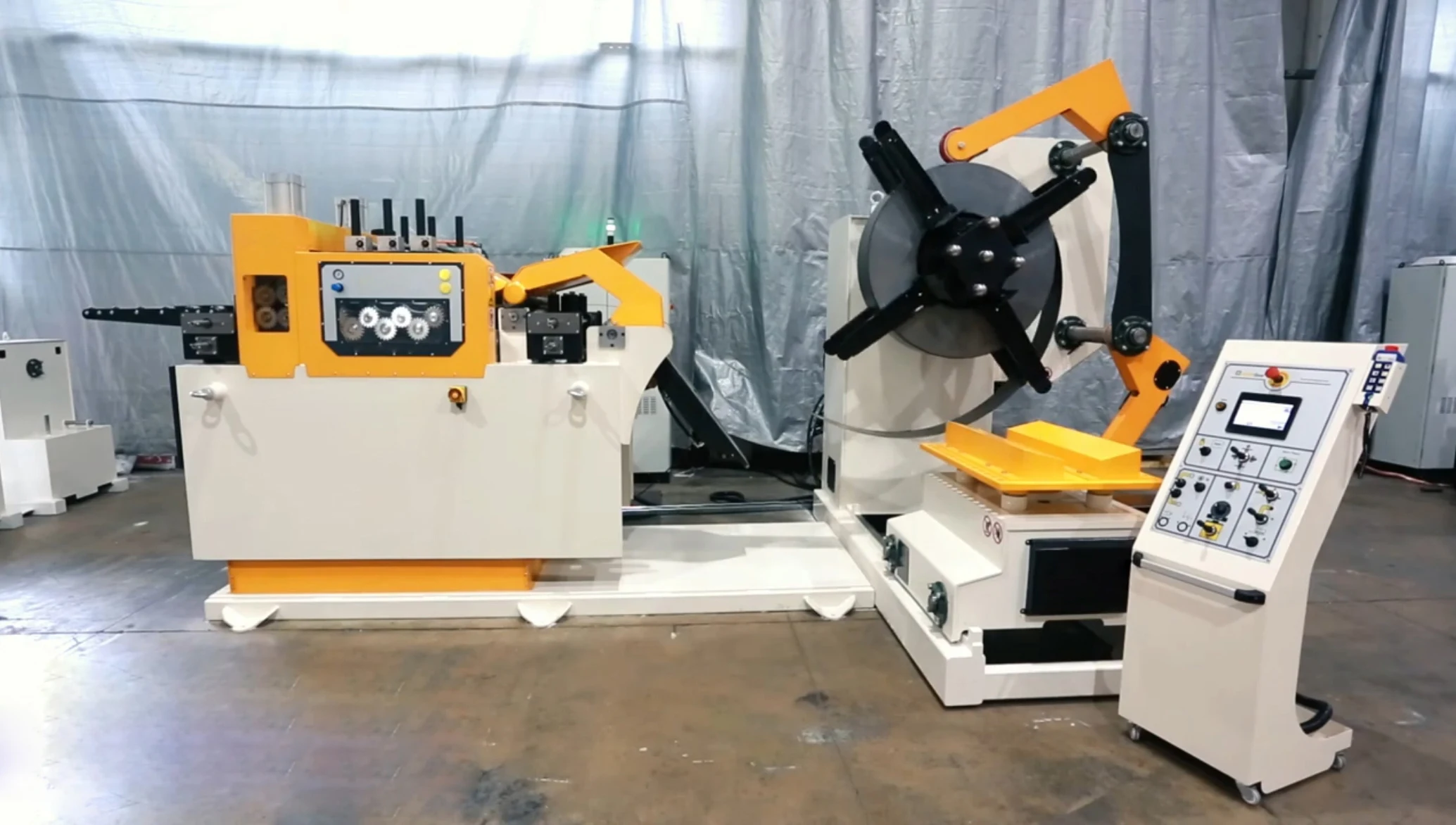

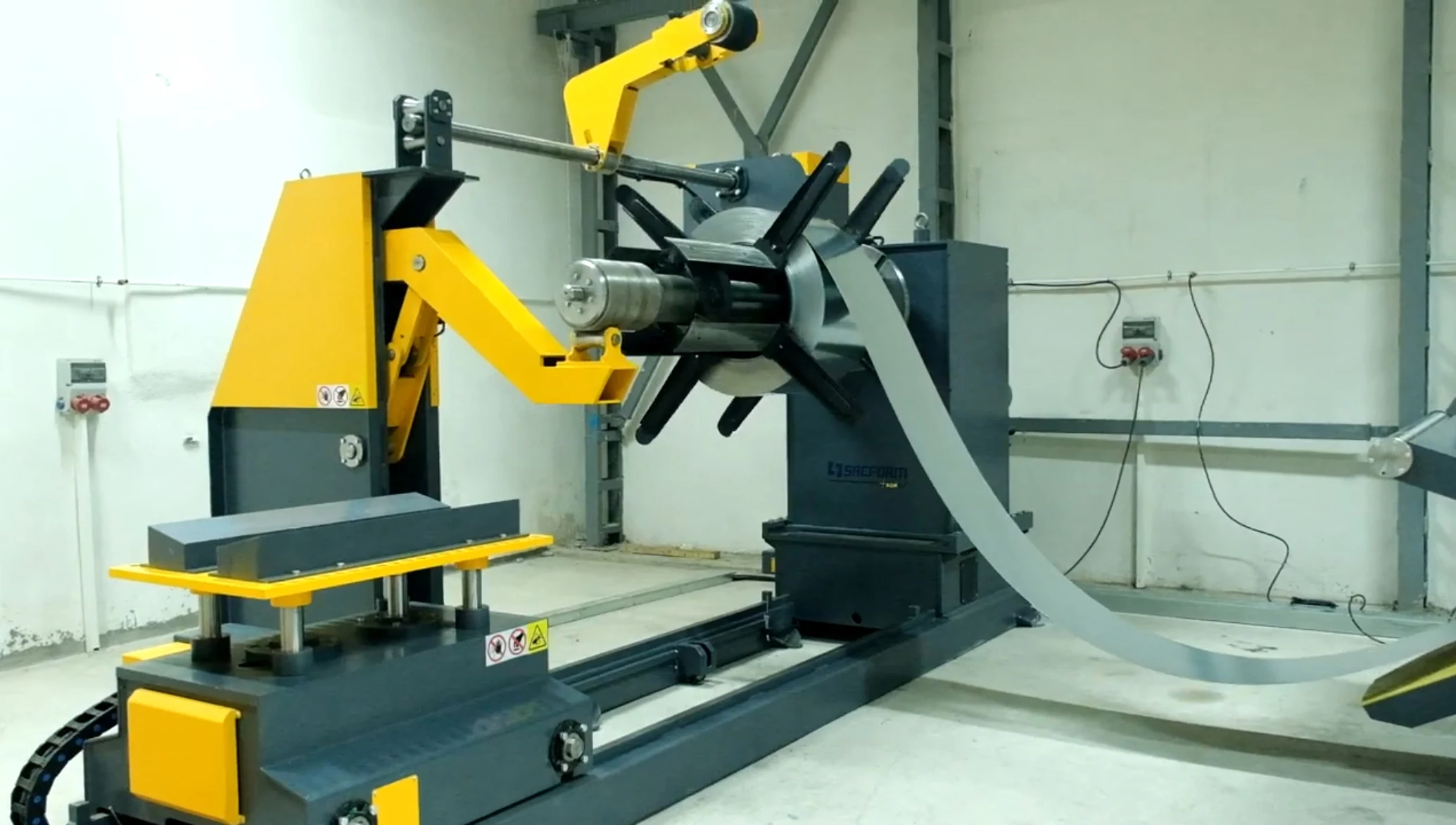

Cut to Length Line Machine Steel Coil Straightening and Leveling Steel Plate Cutting Machine

US $27,000.00-30,000.00 / set

1 set(s)Minimum order

cutting width (mm):

300 - 1600 mm

material thickness(mm):

0.3 - 6 mm

cutting speed(m/min):

40 - 80 m/min

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| cutting width (mm) | 300 - 1600 mm |

|---|---|

| material thickness(mm) | 0.3 - 6 mm |

| cutting speed(m/min) | 40 - 80 m/min |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| coil weight (t) | 10-30 |

| leveling precision(±mm/m) | 1 ±mm/m |

| place of origin | Hebei, China |

| brand name | KEFA |

| voltage | 380V 60HZ 3PH |

| rated power | Customized |

| dimension(l*w*h) | Subject To Real Line |

| key selling points | Easy to Operate |

| warranty | 1 Year |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Condition | New |

| Applicable Industries | Energy & Mining, Construction works |

| Showroom Location | None |

| Weight | 888 |

| Year | 2021 |

Product Detail

PRODUCT ADVANTAGES

01

supplied

Manufacturer

High capacity Lines with minimum area needs.Low cost, High quality,Maximum efficiency.

02

CONTROL

PANEL

Easy operation and maintenance with high level automation.

03

High quality

Accurate surface treatment with high-quality components

PRODUCT INFORMATION

KEFA-Cut to length Lines

The cut-to-length process involves slicing large metal coils into manageable lengths. This process incorporates several large machines, together known as a “cut to length line”.

This process is perfect for hard or thick materials like steel, stainless steel, and aluminum. Cut-to-length machines work quickly and can accommodate precise measurements, so it’s an ideal cutting method for many different applications.

many materials are perfect for the length line, which is one of the reasons it’s such a popular process.

The most common raw materials used in cut-to-length processing are aluminum and steel. These metals hold up well throughout the coiling, uncoiling, cutting, and stacking phases. They’re also easily processed after they’ve been cut into workable sheets. After they go through the cut to length line, they can be turned into a variety of different products.

This process is perfect for hard or thick materials like steel, stainless steel, and aluminum. Cut-to-length machines work quickly and can accommodate precise measurements, so it’s an ideal cutting method for many different applications.

many materials are perfect for the length line, which is one of the reasons it’s such a popular process.

The most common raw materials used in cut-to-length processing are aluminum and steel. These metals hold up well throughout the coiling, uncoiling, cutting, and stacking phases. They’re also easily processed after they’ve been cut into workable sheets. After they go through the cut to length line, they can be turned into a variety of different products.

Cut to length Line Units: | ||

Coil Upload Car | Single Cone Hydraulic Decoiler | |

Coil End Press Feeding Device | 4Hi Precision Plate Leveling Machine | |

Rapid Plate Shearing Machine | Conveyor Table | |

Auto Stacker | Hydraulic System | |

PLC Control System And Power Supply | ||

EXCLUSIVE SERVICE

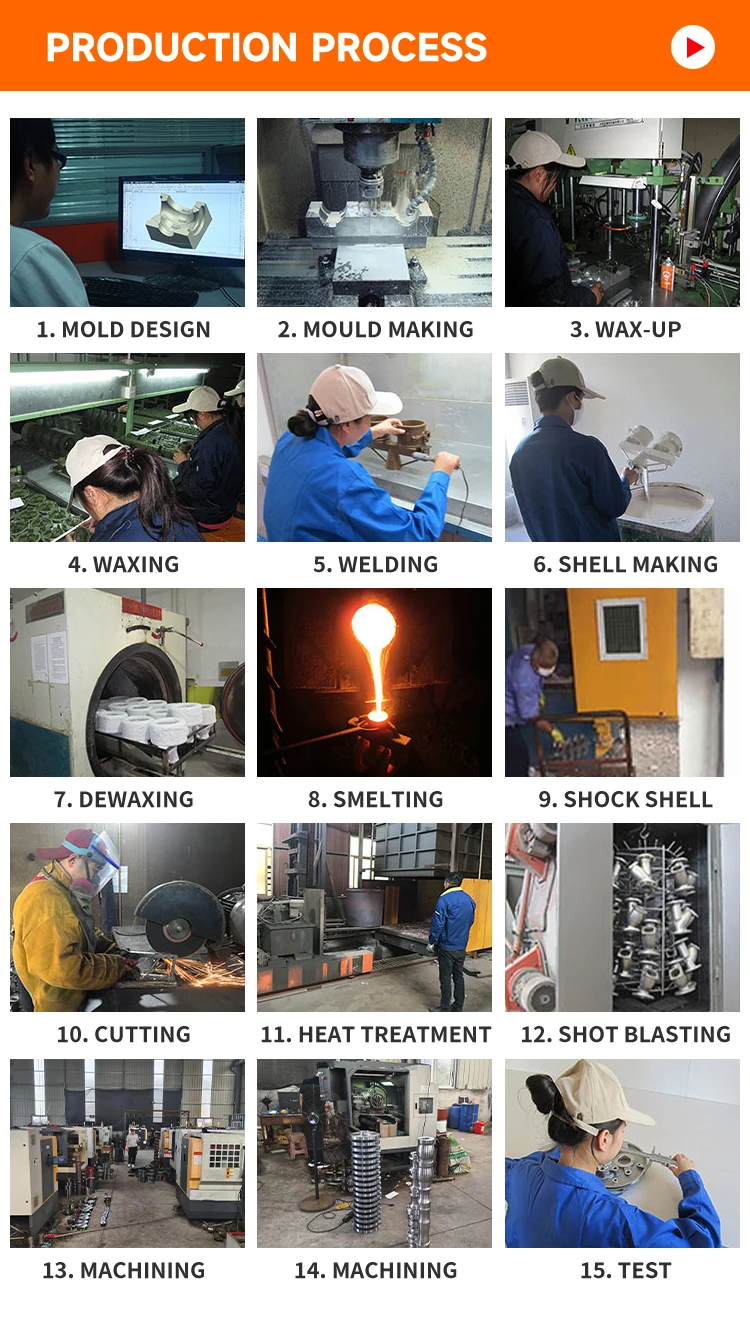

PRODUCTION PROCESS

TESTING EQUIPMENT

PRODUCT LIST

·SCAFFOLD MAKING MACHINE· |

·PORTABLE ROLLFORMER· |

·SPLIT SETROCK BOLT MACHINE· |

·SHUTTER PROFILE MACHINE· |

·ELECTRICAL ROLLFORMING MACHINE· |

·RACK ROLL FORMING MACHINE· |

·ROAD GUARDRAIL MACHINE· |

·BIN/SILO MAKING MACHINE· |

·DRYWALL PROFILE MACHINE· |

·ROOFING PANELROLL FORMING MACHINE· |

·SHIPPING CONTAINER PROFILE MACHINE· |

·METAL DECK ROLLFORM MACHINE· |

·WALLCLADDING ROLLFORMING MACHINE· |

·PURLIN/CHANNELROLL FORMING MACHINE· |

·SLITTING/LEVELING/CUTTING LINE· |

·TRAILER PROFILE MACHINE· |

·AGRICULTURAL ROLLFORM MACHINE· |

·DOOR & WINDOW FRAME MACHINE· |

·FENCE ROLL FORMING MACHINE· |

We are a leading manufacturer specializing in custom cold roll forming equipment and automatic production lines. With astrong focus on innovation and quality,we pride ourselves on delivering top-of-the-line solutions to meet the diverse needs of our clients.

our extensive range of roll forming machines includes over a hundred types, Road Guardrail Machine …and many more.We ensure that all our products are manufactured to the highest standards,using cutting-edge technology and premium materials.

our team of skilled professionals is dedicated to delivering reliable and efficient equipment tailored to meet the specific requirements of our clients. For inquiries,customized solutions,or more information about our products and services,please feel free to reach out to us.

Q HOW TO MAINTAIN THE MACHINE?

A add mechanical lubrication equipment to chain, bearing and cutting slideevery month. Add mechanical lubrication to the case every half a year.

Q DO YOU SELL ONLY STANDARD MACHINES?

A No, most of our machines are built according to customers specifications,using top brand name components.

Q HOW MANY WORKERS TO OPERATE THE MACHINE?

A Only 1-2 workers.

Q HOW TO VISIT YOUR COMPANY?

A A.Fly to TlANJlN airport: By high speed train From TlANJlN Station to CangzhouWest Station(1 hour), then we can pick you up .

B.Fly to Beijing airport: By high speed train From Beijing Nan Station toCangzhou West Station(1 hour), then we can pick you up .

C.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao toCangzhou West station(4.5 hours), then we can pick you up.

Q WHAT CAN YOU DO IF THE MACHINE BROKEN?

A Our machine's warranty period is 12months,if the broken parts can't berepaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

Q HOW CAN ITRUST YOU THAT MACHINES PASTED TESTINGRUNNING BEFORE SHIPPING?

A 1) We record the testing video foryour reference. Or,

2) Please visit company and test machine if convenient.