diesel Engine Driven 150kg/h Dog Food Making Machine Extruder for Pet Food

US $1,350.00-1,550.00 / set

1 set(s)Minimum order

capacity:

50-3500kg/h

condition:

New

place of origin:

Henan, China

brand name:

Eternalwin

type:

Feed Pellet Machine

voltage:

220v/380v

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| capacity | 50-3500kg/h |

|---|---|

| condition | New |

| place of origin | Henan, China |

| brand name | Eternalwin |

| type | Feed Pellet Machine |

| voltage | 220v/380v |

| dimension(l*w*h) | 1360*1600*850mm |

| weight | 350 kg |

| warranty | 1 Year |

| key selling points | High Productivity |

| Name | Pet Feed Extruder |

| Application | Poultry Farm |

| Raw material | Wheat Bran flour corn bone powder |

| Capacity | 40-2000kg/h |

| Suit for | Pet Food Production |

| Pellet size | 1-8mm |

| Floating time | more than 24hrs |

| Keyword 1 | fish food manufacturing machine |

| Keyword 2 | floating fish feed mill |

| Keyword 3 | pellet extruder making machine |

| Applicable Industries | Farms |

| Showroom Location | None |

| Marketing Type | New Product 2020 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Gear, Gearbox, motor |

Product Detail

Product Description

Factory price fish food manufacturing machine floating fish feed mill pellet extruder making machine

The feed extruder is equipped with built-in screw and screw sleeve to lengthen, long material turning time, adjustable

temperature, adjustable output torque, which makes the material expanded with high degree and smooth surface.

Machine Features of Floating Fish Feed Pellet Machine:

1. Can made different size pellet by change the mold

2. Can made floating pellet or sinking pellet or pet food

3. Feed pellet can stay in water at least 24 hours to avoid melt in water

4. During pellet making process, the bacterium was killed,so the pellet was sanitary for eat by animal.

5.The product has novel design, high output and stable operation. The main parts are made of special alloy materials through heat treatment and refining, with high wear resistance and long service life.Product Application

Model | DGP-60B |

Capacity | 120-150kg/h |

Main power | 15KW |

Feeding power | 0.4KW |

Cutter power | 0.4KW |

Screw diameter | Φ60mm |

Pellet size | 1-8mm |

Packing size | 1.36*1.67*0.85m |

Weight | 450kg |

Raw Materials of Floating Fish Feed Pellet Machine:

It can produce a variety of shapes of expanded feed, and can customize the mold according to the requirements. The product outlet has a rotary cutting device with frequency conversion speed regulation, which can arbitrarily adjust the rotation speed of the blade to control the cutting speed and length. With the rapid development of China's national economy, the number of all kinds of pet, fish, shrimp and other expanded feed machines is increasing rapidly, and

they are moving towards commercialization and scale, and the market is extremely hot. There is a great difference between pet food and traditional feeding methods. This equipment uses corn, soybean (bean cake) animal waste as raw materials, which can be directly added into the machine to produce different kinds of pet food with novel particle shape, unique taste, rich nutrition and delicate organization. It is suitable for dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, minks, foxes and other pet flavors.

they are moving towards commercialization and scale, and the market is extremely hot. There is a great difference between pet food and traditional feeding methods. This equipment uses corn, soybean (bean cake) animal waste as raw materials, which can be directly added into the machine to produce different kinds of pet food with novel particle shape, unique taste, rich nutrition and delicate organization. It is suitable for dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, minks, foxes and other pet flavors.

The output products of pet feed extruder:

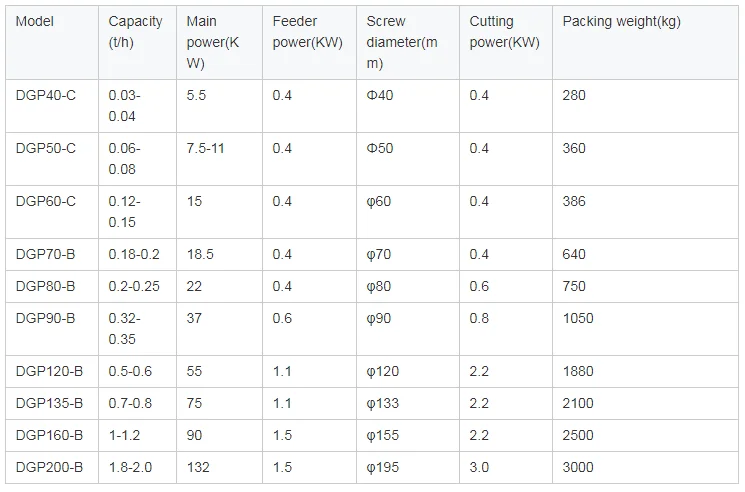

Parameters

Different types of Factory price fish food manufacturing machine floating fish feed mill pellet extruder making machine

Our factory

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Engineers available to service machinery overseas.

Contact with me: