Factory Automatic High Speed Biodegradable T-shirt Plastic Vest Handle Carry Nylon Bag Make Forming Machine Production Line

Other recommendations for your business

Contact us

Quik Detail

| bag type | t-shirt bags production line |

|---|---|

| material | Plastic |

| place of origin | Zhejiang, China |

| brand name | CHOVYTING |

| model number | CW-400V2 |

| voltage | 380V |

| dimension(l*w*h) | 8000x1200x1800mm |

| warranty | 1 YEAR |

| key selling points | Automatic |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor |

| max speed | 220pcs/min |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Brand | Chovyting |

| Speed | 250pcs/min x 2 lines |

| Servo motor | Japan Yaskawa brand |

| PLC | Japan Panasonic brand |

| Cylinder | Taiwan |

| Switch | Schneider, France |

| Inverter | Japan Yaskawa brand |

| Tension control | Automatic |

| Certification | CE, BV, SGS |

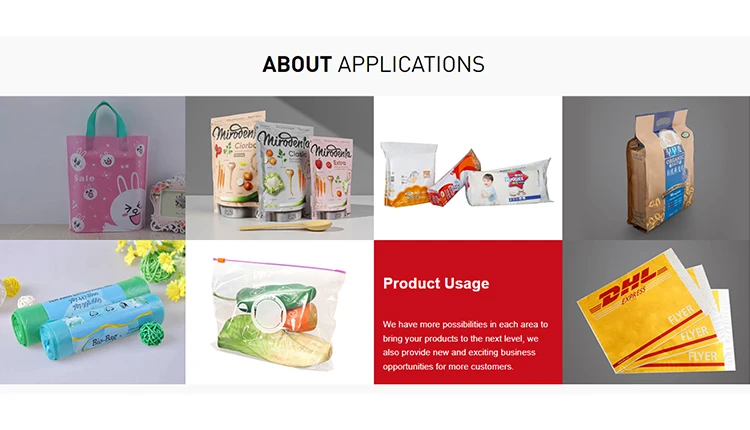

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location | Canada, Turkey, United States, France, Viet Nam, Brazil, Saudi Arabia, Pakistan, Mexico, Spain, Thailand, Kenya, South Korea, UAE, Algeria, Romania, South Africa, Ukraine, Kyrgyzstan, Nigeria, Tajikistan |

| Condition | New |

| Machine Type | Bag Forming Machine |

| Computerized | Yes |

| Marketing Type | Other |

| Warranty of core components | 1 Year |

| Weight | 2300 KG |

Product Detail

It is applied to produce the printed double-lane or non-printed vest bags/ t shirt bags, using HDPE, LDPE roll film. It adopts PLC control,

double servo motors control and the touch screen actual display to finish the feeding, sealing, cutting, punching in one process, which can save man-power greatly and yield good economic result.

Model | CW-500V | CW-400V2 | CW-300V2+GS |

Bag length | 370-700mm | 370-700mm | 370-700mm |

Width of bag making(Max.) | 500mm | 400mmx2Line | 300mmx2Line |

Width size of cutting knife | 580mm | 480mmx2Line | 380mmx2Line |

Speed of bag making(Max.) | 250pcs | 250pcsx2Line | 220pcsx2Line |

Line speed | 125M/min | 125M/min | 100M/min |

Total power | 10KW | 18.5KW | 20KW |

Machine weight | 2800kg | 3100kg | 3800kg |

Machine dimension | 8000x1350x1800mm | 8000x1850x1800mm | 10000x2000x2000mm |

2. The whole set of bags has design of swaying ,no paste between two bags mouth(ITALY DESIGN)

3. Fully automatic tacking of whole set and levelling stack design

2. the motor of clip for clamp the bag is Ac inverter motor control 1.5KW

3. Automatic collect bags and finish stack bags with double fold device