Factory Price HP100 Cone Crusher Mantle Core HP200 Cone Crusher Mantle Core HP300 Cone Crusher Mantle Core

US $1.83 / kilogram

1000 kilogram(s)Minimum order

Warranty:

Unavailable

Weight (KG):

1000

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Place of Origin:

Guangdong, China

Brand Name:

OEM/ODM

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Warranty | Unavailable |

|---|---|

| Weight (KG) | 1000 |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Place of Origin | Guangdong, China |

| Brand Name | OEM/ODM |

| Type | Cone Crusher Bowl Liner |

| Machine Type | Crusher, Heavy Equipment |

| Material | High Manganese Steel, High-strength Alloy Steel |

| Processing Type | Casting |

| Use | Ore Mining |

| Product name | Crusher Spare Parts |

| Usage | Crushing Etc |

| Application | Construction |

| Size | Customize Size |

| Advantage | Wear Resistant |

| Packing | Wooden Pallets |

| Color | Customized |

| Certification | ISO9001:2008 |

| Condition | New |

| Applicable Industries | Energy & Mining |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

Product Detail

Company Profile

Guangdong Lieb Heavy Technology Co., Ltd. is a professional mining machinery equipment and wear parts manufacturer integrating design, development, manufacturing and sales. Our company was founded in 1985 and covers an area of 40,000 square meters. Our technical equipment is at the leading domestic level, with a full set of steel casting equipment, large-scale processing equipment and related testing methods, and advanced water glass modeling and lost foam casting technology. The surface of our product is smooth and the internal structure is uniform, the annual production capacity is more than 20,000 tons. Lieb Heavy has been producing in this industry for more than 35 years, with strong technical advantages and rich experience in the production of wear-resistant castings. We specialize in the production of wear-resistant parts for crushers such as high-manganese steel wear-resistant castings, high-chromium wear-resistant castings, and carbon alloy steel castings. Our products can be used for spare and wear parts of many crusher brands . Our products are exported to more than 30 countries around the world, such as the United States, Russia, Mexico, Chile, Peru, Australia, Japan, South Korea, Thailand, South Africa, etc. Lieb Heavy is committed to providing global customers with a one-stop solution for satisfactory products and best services. Our mission is to provide our customers with the highest quality replacement parts, assemblies and services to improve life cycle performance and save costs.

We look forward to being your best partner, working hand in hand with you and growing together.

Products Description

Main Product

Available Model For Crusher Series | ||||||||

Series | Types | |||||||

lHP | lHP100, lHP200, lHP300, lHP400, lHP500, lHP800, lHP3, lHP4, lHP5, lHP6, lHP7, lHP8 | |||||||

lGP | lGP11F, lGP11M, lGP100, lGP200, lGP300, lGP550, lGP100S ,lGP200S, lGP300S, lGP500S | |||||||

CH | CH420, CH330, CH430, CH440, CH660, CH870, CH880 | |||||||

H | H2800, H3800, H4800, H6800, H7800, H8800, H2000, H3000, H4000, H8000 | |||||||

S | S2800, S3800, S4800, S6800, S2000, S3000, S4000, S6000 | |||||||

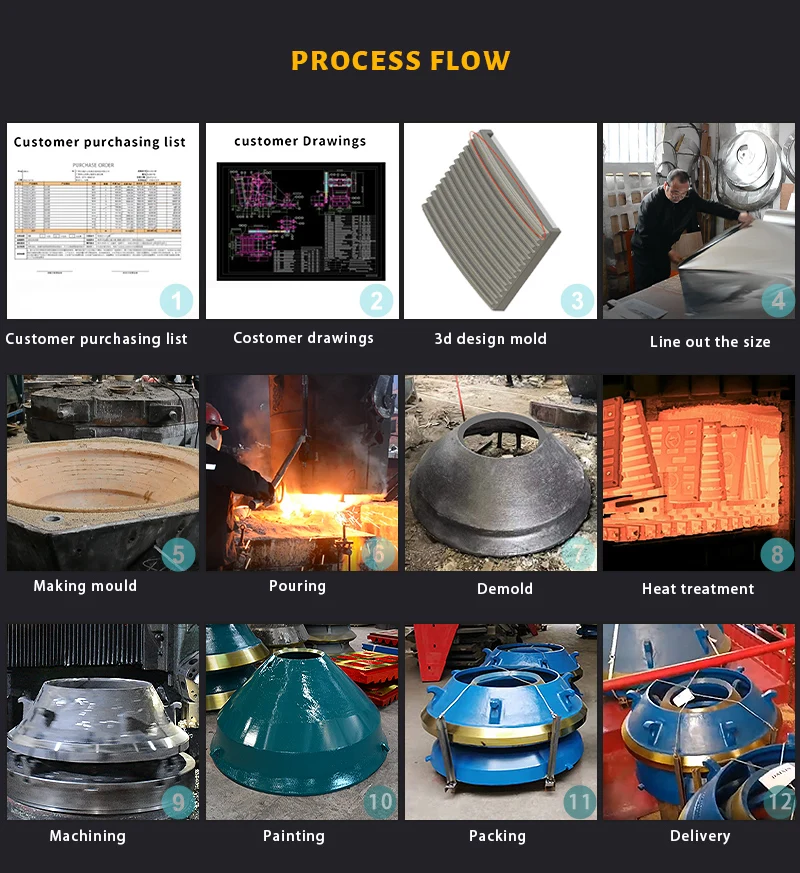

Manufacturing Technique

Product packaging

Our Advantages

1. Strict Casting Standards & advanced manufacturing processes.

2. Our products smooth surface, accurate dimensions and weight, high hardness, high wear resistance and longer life.

3. Advanced manufacturing technology, produce strictly according to original process flow & original drawings.

4. Decreased unexpected downtimes and save cost.

5. Better fit for quick and easy replacement.

6. Design improvements increase crusher efficiency and prevent premature erosion.

7. Fast Delivery - Large inventory of consumable parts for regular models of jaw crusher/cone crusher/roller crusher to ensure reliable delivery.

8. We provide a one-stop service integrating mining equipment planning, design, measurement, production, delivery, installation, and after-sales service.

2. Our products smooth surface, accurate dimensions and weight, high hardness, high wear resistance and longer life.

3. Advanced manufacturing technology, produce strictly according to original process flow & original drawings.

4. Decreased unexpected downtimes and save cost.

5. Better fit for quick and easy replacement.

6. Design improvements increase crusher efficiency and prevent premature erosion.

7. Fast Delivery - Large inventory of consumable parts for regular models of jaw crusher/cone crusher/roller crusher to ensure reliable delivery.

8. We provide a one-stop service integrating mining equipment planning, design, measurement, production, delivery, installation, and after-sales service.

Brand Supported

Certifications