FETECH Custom Scale Hydrocyclone Filter Group Mineral Separator Gold, Copper Classifying Equipment Hydro Cyclone Hot Sale

1 set(s)Minimum order

Type:

Sprial Separator, Gravity Separator

Production Capacity:

20-150 Ton /Hour

Place of Origin:

Guangdong, China

Brand Name:

FETECH

Dimension(L*W*H):

Customizable

Weight:

500 KG

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Sprial Separator, Gravity Separator |

|---|---|

| Production Capacity | 20-150 Ton /Hour |

| Place of Origin | Guangdong, China |

| Brand Name | FETECH |

| Dimension(L*W*H) | Customizable |

| Weight | 500 KG |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Other, Fiber Glass |

| Key Selling Points | High Productivity Long working Life |

| Product name | Spiral Chute Separator for Iron Titanium Chromium |

| MOQ | 1 Set |

| Processing capacity | Capacity Customizable |

| After-sales Service Provided | 0.5-10 Year Flexible Warraty |

| Factory Visit | Welcomed Warmly |

| Function 1 | sorting iron,ilmenite,chromite,pyrite,zircon,rutile,monazite |

| Function 2 | sorting phosphotyrite,tungsten,tin,tantalum,niobium |

| Application | Iron Titanium Chromium Tungsten Tantalum Niobium Tin Gold |

Product Detail

Hydrocyclone Filter

Gold Mineral Separator, also called Hydraulic cyclone, which is a high efficient grading and de-sliming equipment of fine-particle materialis and it is mainly applied to the process of second paragraph grinding, coarse or concentrates re-grinding and the closed-circuit composed by mechanical grading machine, its grading operation is according to the particle size. In closed circuit grinding system, it features high classification efficiency and fine over fall fineness under high mine concentration.

Working Principle

The feed is introduced under pressure through the trangential entry which imparts a swirling motion to the pulp. This generates a vortex in the cyclone, with a low pressure zone along the vertical axis.An air core develops along the axis ,normally connected to the atmosphere through the apex opening, but in part created by dissolved air coming out of solution in the zone of low pressure.

Hydroclone have repaled mechanical classifiers in many modern grinding plants,as they are more efficent, especially in the finer size ranges,they also need less floor space and consume less power. Due to the relatively short residence time of particles within the cyclone,the mill circuit can rapidly be brought into balance if any changes are made abd oxidation of particels within the circuit is reduced.

Working Principle

The feed is introduced under pressure through the trangential entry which imparts a swirling motion to the pulp. This generates a vortex in the cyclone, with a low pressure zone along the vertical axis.An air core develops along the axis ,normally connected to the atmosphere through the apex opening, but in part created by dissolved air coming out of solution in the zone of low pressure.

Hydroclone have repaled mechanical classifiers in many modern grinding plants,as they are more efficent, especially in the finer size ranges,they also need less floor space and consume less power. Due to the relatively short residence time of particles within the cyclone,the mill circuit can rapidly be brought into balance if any changes are made abd oxidation of particels within the circuit is reduced.

Widely Applications

1.A hydrocyclone is most often used to separate "heavies" from a liquid mixture originating at a centrifugal pump or some othe continuous source of pressurized liquid.

2.A hydrocyclone is most likely to be the right choice for processes where "lights" are the greater part of the mixture and where the "heavies" settle fairly easily.

3.Generally, hydrocyclones are used in continuous flow systems so that the instantaneous liquid inflow to the hydrocyclone is equal to the total instantaneous outflow of "lights" plus "heavies".

4.In cases where "heavies" are a very small part of the whole liquid, it is sometimes advantageous to accumulate them in the bottom of the hydrocyclone for batchwise removal.

Model | Specification | Capacity (m³/h) | Separation Particle Size (μm) | Diameter of Overflow Port (mm) | Diameter of Dust- Setting Nozzle (mm) | Inlet Pressure (MPa) |

FX-10 | 10 | 0.05-1 | 1-5 | 2-4 | 1-2 | 0.060-0.15 |

FX-25 | 25 | 0.3-1 | 2-10 | 5-8 | 2-5 | 0.060-0.15 |

FX-50 | 50 | 1.5-3 | 5-74 | 11-18 | 3-12 | 0.060-0.15 |

FX-75 | 75 | 2-5 | 5-74 | 15-20 | 6-12 | 0.060-0.15 |

FX-100 | 100 | 5-12 | 10-74 | 20-40 | 8-18 | 0.060-0.15 |

FX-125 | 125 | 8-15 | 20-74 | 25-40 | 8-18 | 0.060-0.15 |

FX-150 | 150 | 10-23 | 25-74 | 30-45 | 8-22 | 0.060-0.15 |

FX-200 | 200 | 17-38 | 28-80 | 40-65 | 16-32 | 0.060-0.15 |

FX-250 | 250 | 24-53 | 30-82 | 65-100 | 16-40 | 0.060-0.15 |

FX-300 | 300 | 40-100 | 36-90 | 65-120 | 20-40 | 0.060-0.15 |

FX-350 | 350 | 56-118 | 40-100 | 80-120 | 30-70 | 0.060-0.15 |

FX-375 | 375 | 74-157 | 42-105 | 90-135 | 30-70 | 0.060-0.15 |

FX-450 | 450 | 90-192 | 44-110 | 100-150 | 30-70 | 0.060-0.15 |

FX-500 | 500 | 128-300 | 50-115 | 130-220 | 35-100 | 0.060-0.15 |

FX-600 | 600 | 200-468 | 57-125 | 160-260 | 65-110 | 0.060-0.15 |

FX-660 | 660 | 237-524 | 60-130 | 180-280 | 80-150 | 0.060-0.15 |

Company Profile

Company Profile: Future Explorer Technical Eqiupment Co.,Ltd (FETECH)

The R&D technical team is located in Shenzhen, Guangdong,a high-tech industry gathering city in China. The factory is located in Shicheng County, Jiangxi Province, covering an area of around 40,000m².

It has more than 200 sets of large-scale modern mechanical processing equipment, smelting and casting equipment, and more than 50 professional mechanical manufacturing engineers, mineral processing engineers, and professional equipment installation engineers, including 10+ senior engineers, 30+ junior engineers, and 150+ workers.supporting our company's strong production and supply capabilities.

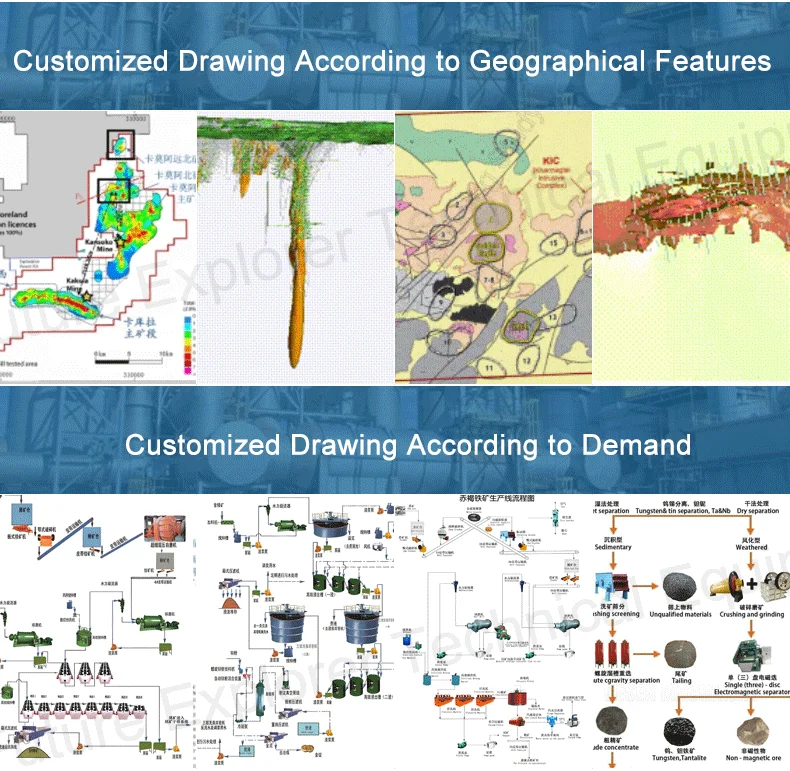

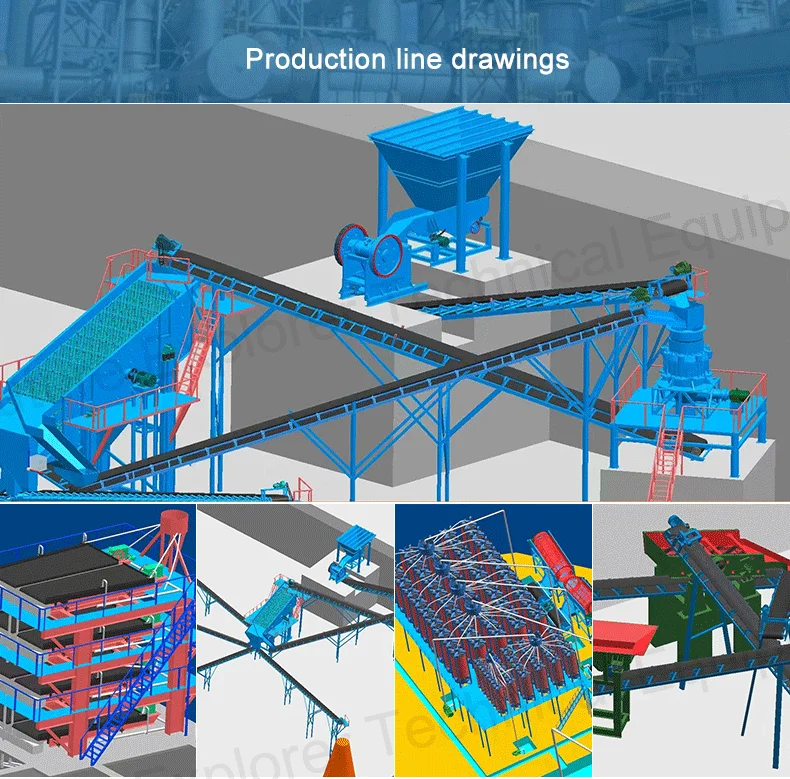

For more than 20 years, we have focused on the R&D, design and production of mining mineral processing equipment. The core founding team has independently designed and developed customized production line one-stop solutions for mining projects in 100+ countries around the world based on customer needs and the local geographical environment of the mine. Including on-site survey, product design, manufacturing, installation, commissioning and after-sales service. In addition,We also maintain long-term cooperation with international and Chinese scientific research institutions of universities to explore new and efficient technologies, improving economic efficiency while protecting the environment

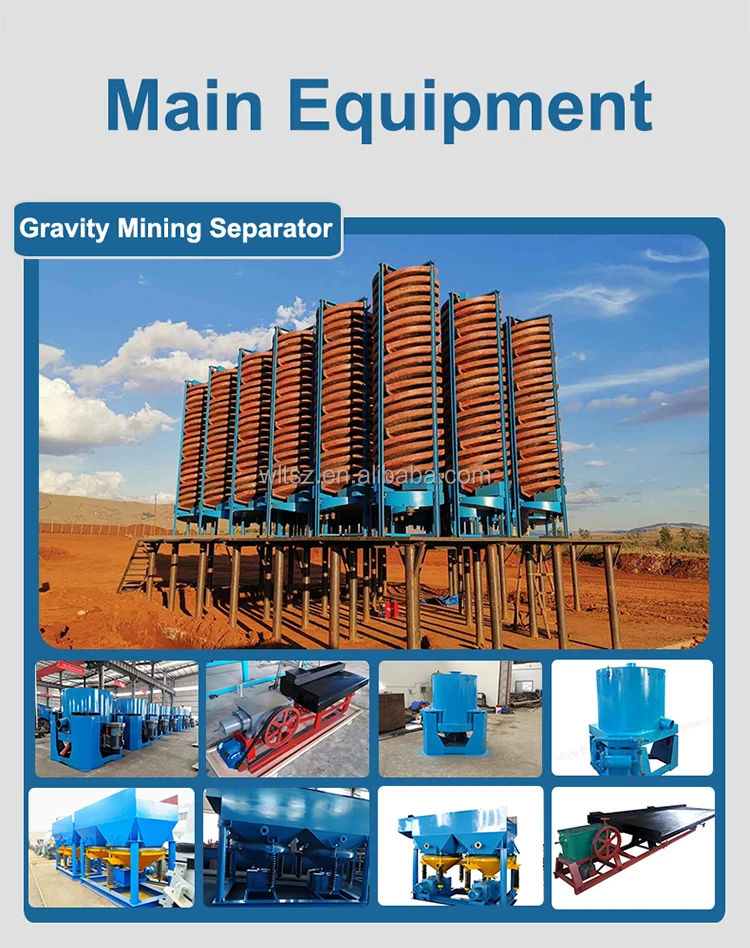

Main products: customized production line solutions for mines, ore washing equipment, gravity separation equipment, flotation equipment, magnetic separation equipment, crushing and grinding equipment, screening and classification equipment, feeding and conveying equipment, mineral processing experimental equipment, excavation equipment and transportation equipment , mobile mining crushing production equipment, sand dredgers, dredgers and other large equipment. Mainly used in mining, coal, quarry, scrap metal recycling and other fields.

Products have passed ISO9001, ISO27001, ISO17020, SGS, IECEX, MSHA, ATEX, ANZEX, CERTEX, GOST-R, IRMA certification

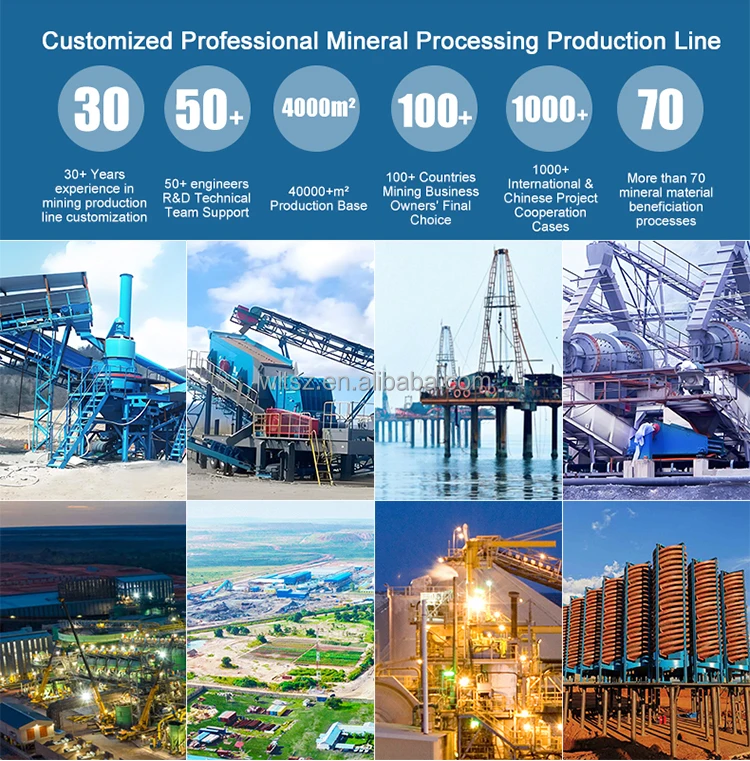

Why Choose FETECH ? (Future Explorer Technical Eqiupment Co.,Ltd )

30+Years experience in mining production line customization

50+engineers R&D Technical Team Support

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

40000+ m² Production Base

100+Countries Mining Plant Owners' Final Choice

1000+ International & Chinese Project Cooperation Cases

70+ Mineral material Beneficiation

We support EPC+M+O Mode (Engineer,Procure,Construct + Operation + Maintenance )

Global Sales Network:

1. Oceania: Australia, New Zealand 2.Africa: South Africa, Sudan, Zimbabwe, Ghana,Tanzania, Uganda, Congo, Zambia, Nigeria,

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

3.Americas: United States, Canada, Brazil, Mexico

4.Europe: Romania, Sweden

5.Asia: South Korea,India, Malaysia, Indonesia, Thailand, Philippines, Vietnam, Myanmar, Mongolia, Russia, Kazakhstan, Uzbekistan,Kyrgyzstan,Tajikistan, Turkmenistan, Turkey, Papua New Guinea

Customer Photos

Certifications