Fully Automatic Roll Welded Wire Mesh Net Making Machine Manufacturer 3-6mm Wire Welding Mesh Machine

US $11,899.00-13,899.00 / set

1 set(s)Minimum order

machine type:

Wire Mesh Making Machine

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

Engine, Gearbox, motor

wire diameter (mm):

2 - 12 mm

production capacity:

300 sets per year

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| machine type | Wire Mesh Making Machine |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | Engine, Gearbox, motor |

| wire diameter (mm) | 2 - 12 mm |

| production capacity | 300 sets per year |

| place of origin | Hebei, China |

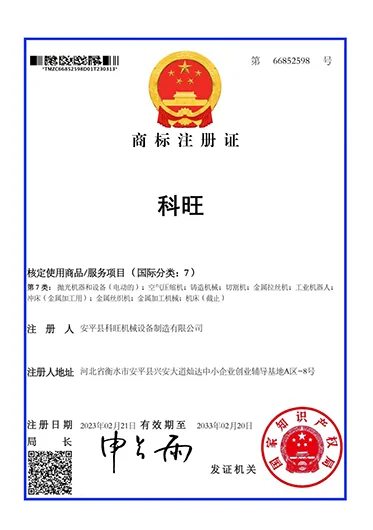

| brand name | KeWang |

| model number | KW-0001 |

| weight (kg) | 6500 |

| power (kw) | 5.5 |

| key selling points | Easy to Operate |

| warranty | 2 years |

| Name | Welded Wire Mesh Machine |

| Type | Fully Automatic |

| Application | Weaving Diamond Wire Mesh |

| Usage | Production Wire Mesh |

| Color | blue or other color |

| Raw material | galvanized wire, steel wire, black wire |

| Machine Wire Dia | 2mm to 12mm |

| Welding Speed | 60-180 times/min |

| Container needed | 1*20GP or 1*40GP |

| Voltage | 220V/380V/415V/440V |

| Condition | New |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Showroom Location | Morocco, Kenya, South Korea, Colombia, South Africa, Turkey, Brazil, India |

Product Detail

Electro Welding Mesh Machine (Roll)

An electro welding mesh machine is a type of equipment used in the manufacturing industry to weld together metal wires to create mesh panels. This machine utilizes electricity to generate heat, which melts the wires at their intersection points, fusing them together to form a strong and durable mesh structure. These mesh panels find applications in various industries, including construction, agriculture, fencing, and manufacturing. The electro welding process ensures precise and consistent welds, resulting in high-quality mesh products suitable for a wide range of uses.

Automatic welded mesh machine is a new type welded wire machine and which is researched and developed by our factory. This equipment is mechatronic welding machine, do without cutting edges which save material, adjustable of distance of warp thread, when input the distance of weft thread to computer, any character can be reach.

Main usage: Welding of fence mesh for railway, highway, bridge and building.

This machine main parameter:

1. Measurement (L × W × H): 8480 mm × 3160 mm × 1700 mm, weight: 4.2 T.

2. Max. welding width: 2.5 m.3. Thread diameter: 2.5 mm - 6 mm.

4. Adjustable electromagnetism motor: 4.0 KW.

5. Power: 380 V.

6. Capacity: 80-200 KW.

7. Adopt automatic welding by software, reduce the demand for electricity and pollution of electric grid.

8. Product support: Net repair welding machine & component /installation kit.

Product advantages

1 Both of line wire and cross wire are fed from wire coils automatically.

2 Raw material can be black wire, galvanized wire or stainless steel wire.

3 One time two or three mesh rolls can be produced.

4 The mesh roll length can be set by counter switch on the control panel.

5 The welding transformers can be adjusted for different wire diameters.

6 The welding time and welding current can be adjusted on the control panel to guarantee solid welding.

7 Sturdy structure and world famous electric components are used like Symens, Schneider, Delta etc.

8 Water cooling transformer is used for hot area.

9 Patent design for process of thick hard black wire. One time two or three mesh rolls can be produced.

1 Both of line wire and cross wire are fed from wire coils automatically.

2 Raw material can be black wire, galvanized wire or stainless steel wire.

3 One time two or three mesh rolls can be produced.

4 The mesh roll length can be set by counter switch on the control panel.

5 The welding transformers can be adjusted for different wire diameters.

6 The welding time and welding current can be adjusted on the control panel to guarantee solid welding.

7 Sturdy structure and world famous electric components are used like Symens, Schneider, Delta etc.

8 Water cooling transformer is used for hot area.

9 Patent design for process of thick hard black wire. One time two or three mesh rolls can be produced.

ANPING COWAN WIRE MESH & MACHINES CO., LTD is a professional company in wire mesh machines and wire mesh fences. Our main products including: chain link fence machine, welded mesh machine, gabion machine, concertina razor wire machine, barbed wire machine, Crimped wire mesh machine, Grassland fence machine, Fixed knot fence machine, PVC wire coating machine and so on. All of the machines will run and produce customer asked specification products in our factory before sending to our customers to make sure the machine’s quality. Moreover, we have 7 days by 10 hour engineer online services to provide after-sales services.

3-Our Team more than 40 employees.

Q1: Whether your machine has warranty?

A1: Yes, for all our machines we provide 2 years warranty and whole life services. For some spare parts we give you extra to make sure you can use more than 2 years.

Q2: As to how to install or how to run the machine, what service you provide?

A2: 1st we have online video step by step to show you how to install and how to run the machine. 90% customers can run the machine by themselves according to the video. 2nd, if you want our engineer go to your country to run, it is also work. But you need to be responsible for the engineers round ticket and accommodation in your country and salary. 3rd, some customers send their engineer to our factory to learn, this way also work. We will provide accommodation here in China.

A1: Yes, for all our machines we provide 2 years warranty and whole life services. For some spare parts we give you extra to make sure you can use more than 2 years.

Q2: As to how to install or how to run the machine, what service you provide?

A2: 1st we have online video step by step to show you how to install and how to run the machine. 90% customers can run the machine by themselves according to the video. 2nd, if you want our engineer go to your country to run, it is also work. But you need to be responsible for the engineers round ticket and accommodation in your country and salary. 3rd, some customers send their engineer to our factory to learn, this way also work. We will provide accommodation here in China.

Q3: Why do you say your machine quality is good?

A3: We also use our machine to produce products, during this way we can keep our machine updating. Secondly, old customers repeat giving us orders when they want to increase production. So, if customers think the machine is good, then this is the best proof for our machine’s quality.