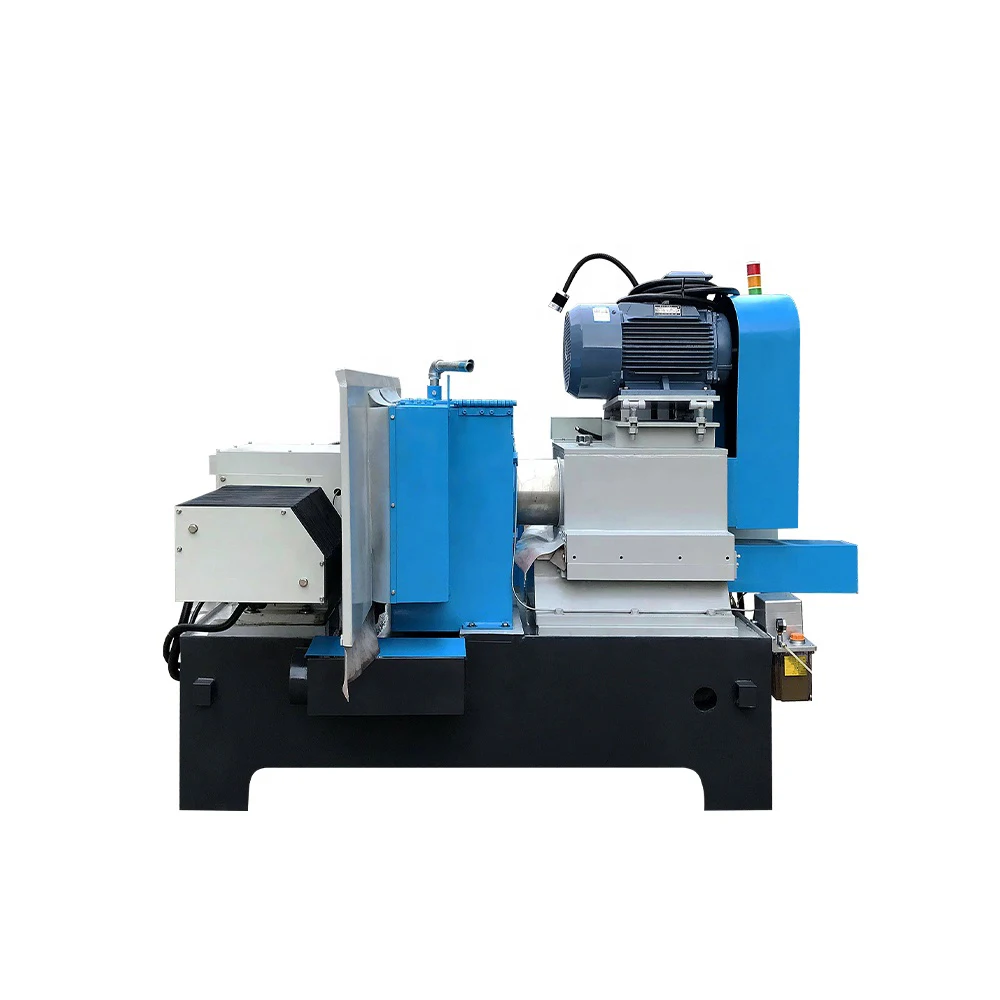

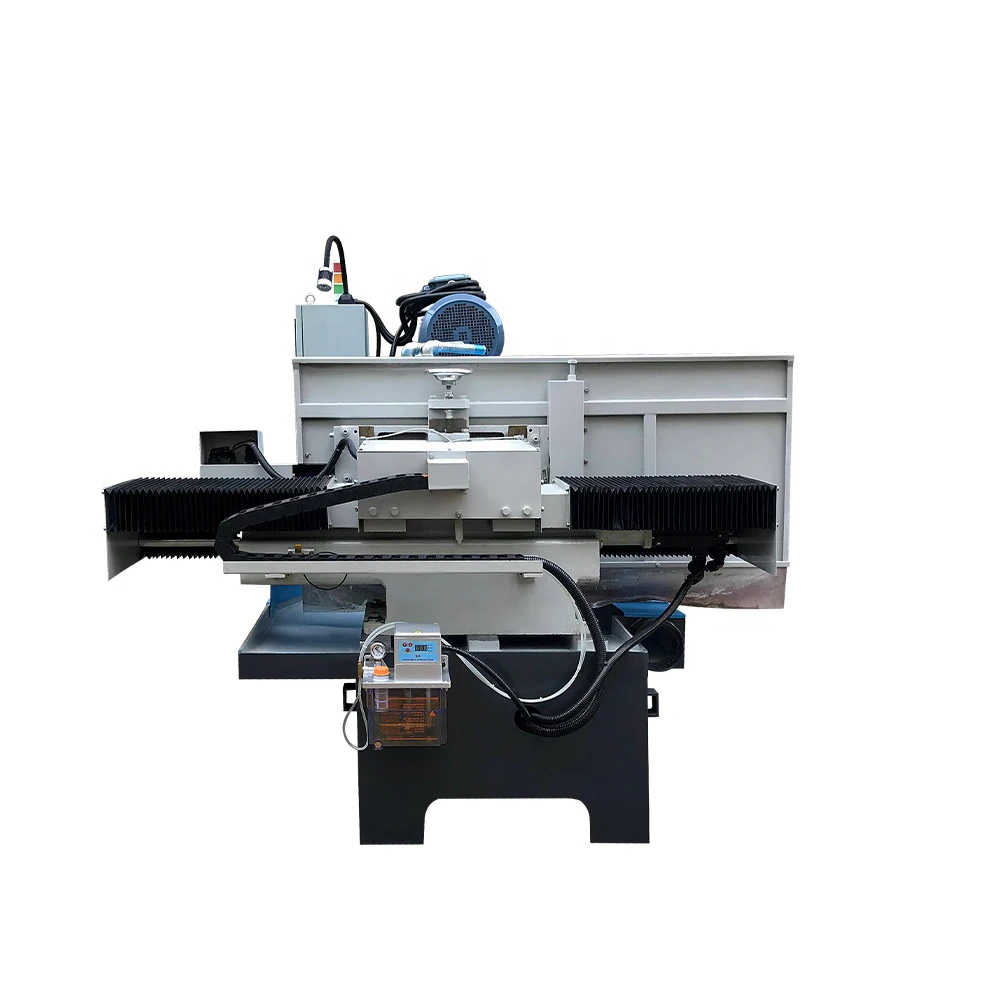

GH-3Z350 CNC 3-Axis Hot Sale Surface Grinding Machine Stainless Steel Knife Surface Grinder Grinding Knife Making Machine

Other recommendations for your business

Contact us

Quik Detail

| type | Knife grinder |

|---|---|

| cnc or not | CNC |

| wheel size(mm) | 355 |

| place of origin | Guangdong, China |

| brand name | GUOHAO MACHINE |

| voltage | 380V 50HZ 3-PHASE |

| dimension(l*w*h) | 2100*1800*1800mm |

| weight (kg) | 3500 |

| power (kw) | 15KW |

| warranty | 1 Year |

| key selling points | 3-axis high precision CNC grinder for ceramic knife, scissor |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, Bearing, Engine, Gear, Pressure vessel, Gearbox, PLC, Pump |

| Type | Surface Grinding Machine |

| Color | Pure white |

| Machine Type | CNC Control |

| CNC system | Huazhong system |

| Axis | 3 axis CNC |

| Keywords | High precision accuracy CNC automatic surface grinding machine |

| Application | Steel, Ceramic |

| Other name | Small knife, Ceramic knife grinding machine |

| Maintenance period | 1 year |

| Model | GH-3Z350 |

| Condition | New |

| Showroom Location | None |

| Applicable Industries | Manufacturing Plant, Retail, Scissor/Knife Manufacturing |

| Marketing Type | Hot Product |

| Warranty of core components | 1 Year |

| Year | Latest |

Product Detail

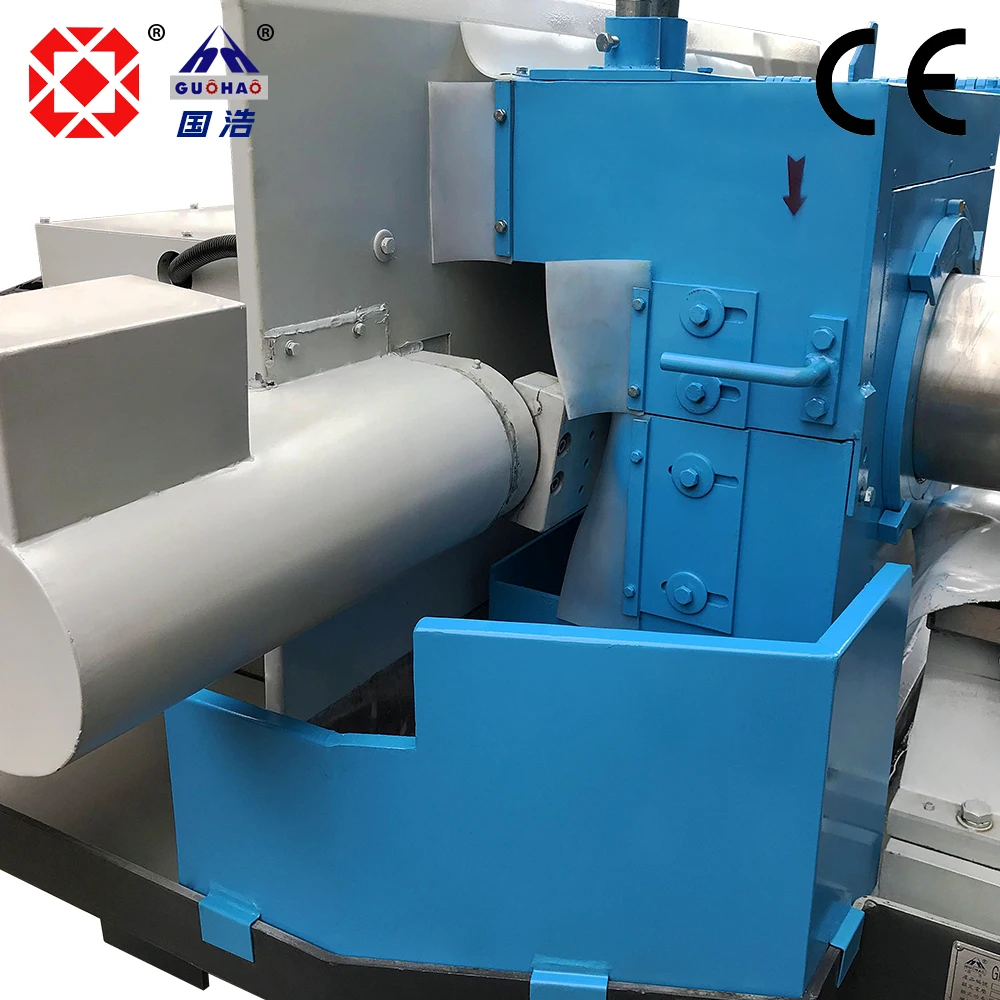

Product name | 3-axis CNC Knife Single-surface Grinding Machine | |

Model no. | GH-3Z350 | |

Main motor power | 15KW 50HZ 380V (Customize depends on actual request) 3-PHASE | |

Grinding wheel linear speed | 30m/s(white corundum grinding wheel) | |

CNC system | Huazhong system | |

Max. travel of main shaft box (Z-axis) | 150mm | |

Valid travel of knife rest (X-axis) | Overall travel 530mm, Grinding length 350mm | |

Swift angle of A-axis | +40°~ -30° | |

Grinding wheel specification | Barrel wheel ∅355x∅275x125mm | |

Machine diamension | 2100x1800x1800mm | |

Machine weight | 3500KG | |

Any technical information not refer in the table please feel free to consult us yingjuan2017@163.com | 3500kg | |

GH-3Z450 3-axis CNC Knife Single-side Grinding Machine

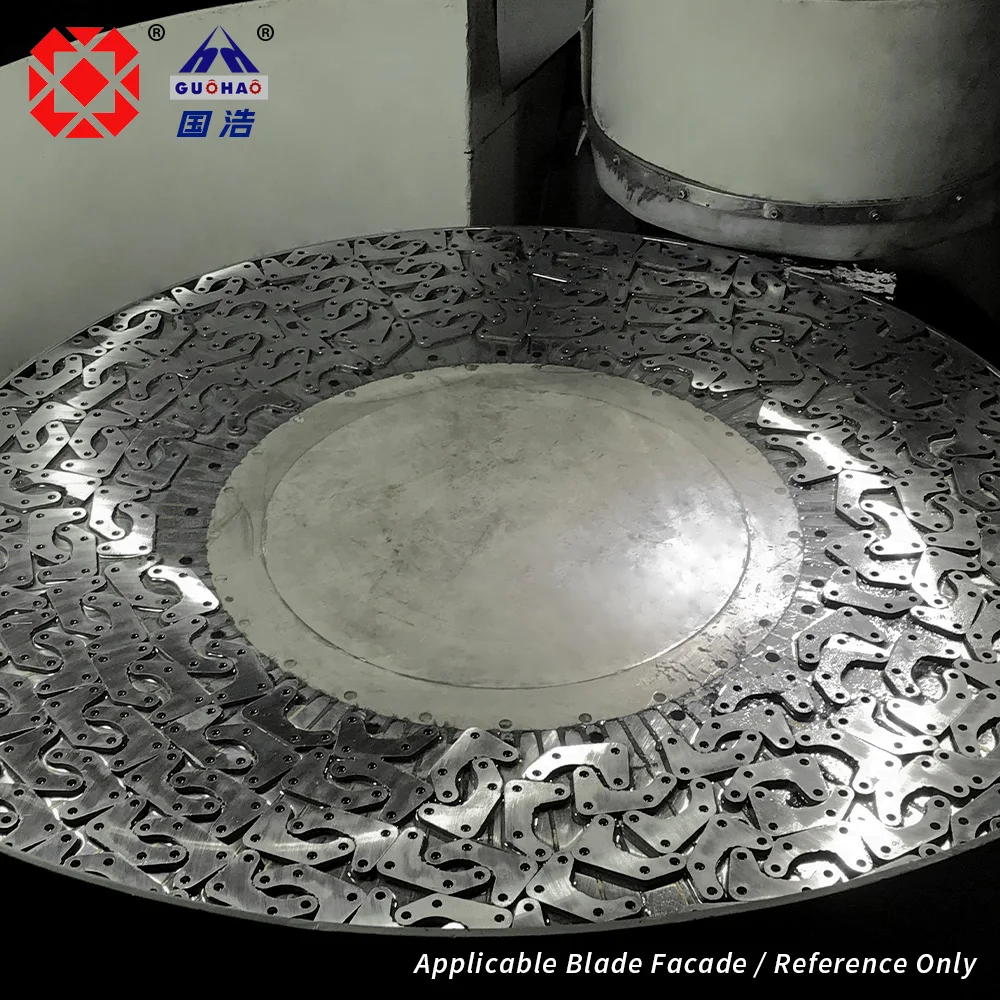

Enable to grind Single-sided grinding, cutting edge, flat Grinding, polishing, grinding bevel, back edge and other processes of Ceramic knives, all kinds of ordinary scissors, tailor shears, chef knives / kitchen knives / choppers, triple steel knives, fruit knives, steel knives, hunting knives, daggers, Damascus, etc. The surface of the produced product is smooth with clear and stable lines.

GH-1000B CNC Vertical Rotary Table Knife Grinding Machine

The machine mainly used for surface grinding of hardware products, such as scissors and knives.

High efficiency one-time grinding and excellent finished surface quality of the products can meet high quality product

requirement.

GH-4Z450F 4-axis CNC Knife Single-side Grinding Machine

GH-400B CNC Vertical Rotary Table Knife Grinding Machine

Mainly used for surface grinding of circular-disk kind of products (such as motorcycle brake discs, food machinery circular blades and etc.)

High efficiency one-time grinding and good surface quality of finished products, can meet the quality requirements of client’s high-quality product processing.

Plywood case(optional)

and international fumigation sign will mark on the case surface.

*The plywood case requires to pay in additional.

Plastic film(default)

The default simplify packing can prevent steam from entering the machine.

PRE-SALES SUPPORT

Inquiry and consult

Sample testing

Visit our company and factory

AFTER-SALES SUPPORT

Training - how to install and how to use the machine

Online Support

TEL.: (0086 0662) 6601950

WECHAT: +86 186 6623 9592

EMAIL: yingjuan2017@163.com

AVAILABLE: 8:30a.m. to 6:00p.m. from MON to SAT