Good Price Mining Machine Gold Copper, Iron, Zinc Lead Mineral Ore Powder Grinding Ball Mill Price

US $11,200.00-15,500.00 / set

1 set(s)Minimum order

Type:

Powder Grinding Machine

Production Capacity:

2.2-160tph

Place of Origin:

Henan, China

Brand Name:

Xingaonai

Voltage:

30-2000kw

Dimension(L*W*H):

various

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Powder Grinding Machine |

|---|---|

| Production Capacity | 2.2-160tph |

| Place of Origin | Henan, China |

| Brand Name | Xingaonai |

| Voltage | 30-2000kw |

| Dimension(L*W*H) | various |

| Weight | 18000 KG |

| Warranty | 2 years |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Bearing, motor, Pump, Gear, PLC, Other, Pressure vessel, Engine, Gearbox |

| Key Selling Points | Automatic |

| Product name | Mineral Gold Powder Making Machine Grinder Ball Mill Price |

| Application | powder grinding machine |

| Max feeding size | 25mm |

| Discharge size | 0-0.074mm, 40mesh, 80 mesh, 200mesh 325 mesh |

| Delivery Time | 15-45 Days |

| Spare parts supply | Lifelong Time |

| Liner Material | ZGMn13 |

| Bearing brand | ZWZ China first brand |

| Online Service Time | 24h*7 |

| Installation | Under Technical Guidance |

Product Detail

Products Description

Wet Grinding Mill

1.Large application range, simple structure and convenient maintenance;

2.Large capacity and continuous work are very obvious

2.Large capacity and continuous work are very obvious

Capacity range from 1-130 tph, final product can be 30- 500 mesh !

3.Barrel lining and grinding media can apply various abrasive materials;

4.Installation and adjustment are very convenient and easy to be operated.

3.Barrel lining and grinding media can apply various abrasive materials;

4.Installation and adjustment are very convenient and easy to be operated.

For different use, there are different discharge method of the ball mill

Normally there are grate discharge, overflow discharge, end and side discharge method.

Machine Working Principle

The working principle of the wet ball mill

The wet ball mill needs to add an appropriate amount of water or absolute ethanol during the grinding process, which means that there are certain requirements for the concentration of grinding. The amount of water is determined by the nature of the material. Qualified materials are discharged out of the cylinder through the discharge part, and unqualified materials are returned to the wet ball mill again for re-grinding.

Production Line

Above is how we make ball mill step by step.

Gold Copper, Iron, Zinc Lead Mineral Ore Powder Grinding Mining Separation with Ball Mill Grinding Machine good price

Product Parameters

Model | shell rotation speed (r/min) | Ball load (t) | Feeding size(mm) | Discharging size(mm) | Capacity (t/h) | Power (KW) | Weight (T) |

900×1800 | 38 | 1.5 | ≤20 | 0.075 -0.89 | 0.65 -2 | 18.5 | 3.6 |

900×2100 | 38 | 1.3-1.4 | ≤15 | 0.075 -0.83 | 0.7-3.5 | 18.5 | 3.9 |

900×3000 | 38 | 2.7 | ≤20 | 0.075 -0.89 | 1.1-3.5 | 22 | 4.5 |

1200×2400 | 32 | 3.8 | ≤25 | 0.0745-0.6 | 1.5-4.8 | 30 | 11.5 |

1200×2800 | 32 | 3.3-3.5 | ≤25 | 0.0745-0.6 | 2-6 | 30 | 12.8 |

1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 13 |

1200×4500 | 32 | 7 | ≤25 | 0.074 -0.4 | 1.6-5.8 | 45 | 13.8 |

1500×3000 | 27 | 8 | ≤25 | 0.074 -0.4 | 2-5 | 75 | 17 |

1500 ×3500 | 27 | 6.75-6.4 | ≤25 | 0.075 -0.4 | 3-7 | 75 | 17.5 |

1500×4500 | 27 | 14 | ≤25 | 0.074 -0.4 | 3.5-12 | 110 | 21 |

1500×5700 | 27 | 15 | ≤25 | 0.074 -0.4 | 3.5-8 | 115 | 24.7 |

1830×3000 | 24 | 18 | ≤25 | 0.074 -0.4 | 4-10 | 130 | 28 |

1800×3600 | 24 | 10.6-11.35 | ≤25 | 0.075 -0.4 | 5-22 | 130 | 30 |

1830*4500 | 25.4 | 15 | <=25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

1830×6400 | 24.1 | 21 | ≤25 | 0.074~0.4 | 6.5-15 | 210 | 34 |

1830×7000 | 24 | 25 | ≤25 | 0.074 -0.4 | 7.5-17 | 210 | 36 |

2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 39 |

2100×3600 | 22 | 14-15.2 | ≤25 | 0.075 -0.4 | 15-36 | 370 | 42 |

2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 43.8 |

2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 56.6 |

2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 45.5 |

2200×5500 | 21 | 30 | ≤25 | 0.074 -0.4 | 10-20 | 210 | 48.5 |

2200×6500 | 21 | 31 | ≤25 | 0.074 -0.4 | 14-26 | 380 | 52.8 |

2200*7000 | 21.7 | 35 | <=25 | 0.074-0.4 | 15-28 | 380 | 54 |

2200×7500 | 21 | 33 | ≤25 | 0.074 -0.4 | 16-29 | 380 | 56 |

2400×3000 | 20.6 | 15.5-16.6 | ≤25 | 0.075 -0.4 | 22-24 | 245 | 59 |

2400×4500 | 21 | 30 | ≤25 | 0.074 -0.4 | 8.5-60 | 380 | 65 |

2700×3600 | 20.6 | 39 | ≤25 | 0.074 -0.4 | 12-70 | 400 | 91.3 |

2700×4000 | 20.7 | 40 | ≤25 | 0.074 -0.4 | 12-80 | 400 | 94 |

2700×4500 | 20.7 | 48 | ≤25 | 0.074 -0.4 | 12-90 | 430 | 102 |

3200×4500 | 18 | 65 | ≤25 | 0.075-0.4 | 30-90 | 800 | 137 |

Packaging & Logistics

Packing

1.The equipment and wearing parts are packed in plastic film and wooden box.

2.FCL:Shipped in standard export container.

3.Various packaging methods can be provided according to customer requirements, such as: fumigation-free wooden boxes, steel boxes, etc.

Sea freight

We ship the goods to China's main seaports, such as Qingdao, Tianjin, Shanghai, etc., and then ship the equipment to your country by sea.

Why Choose Us

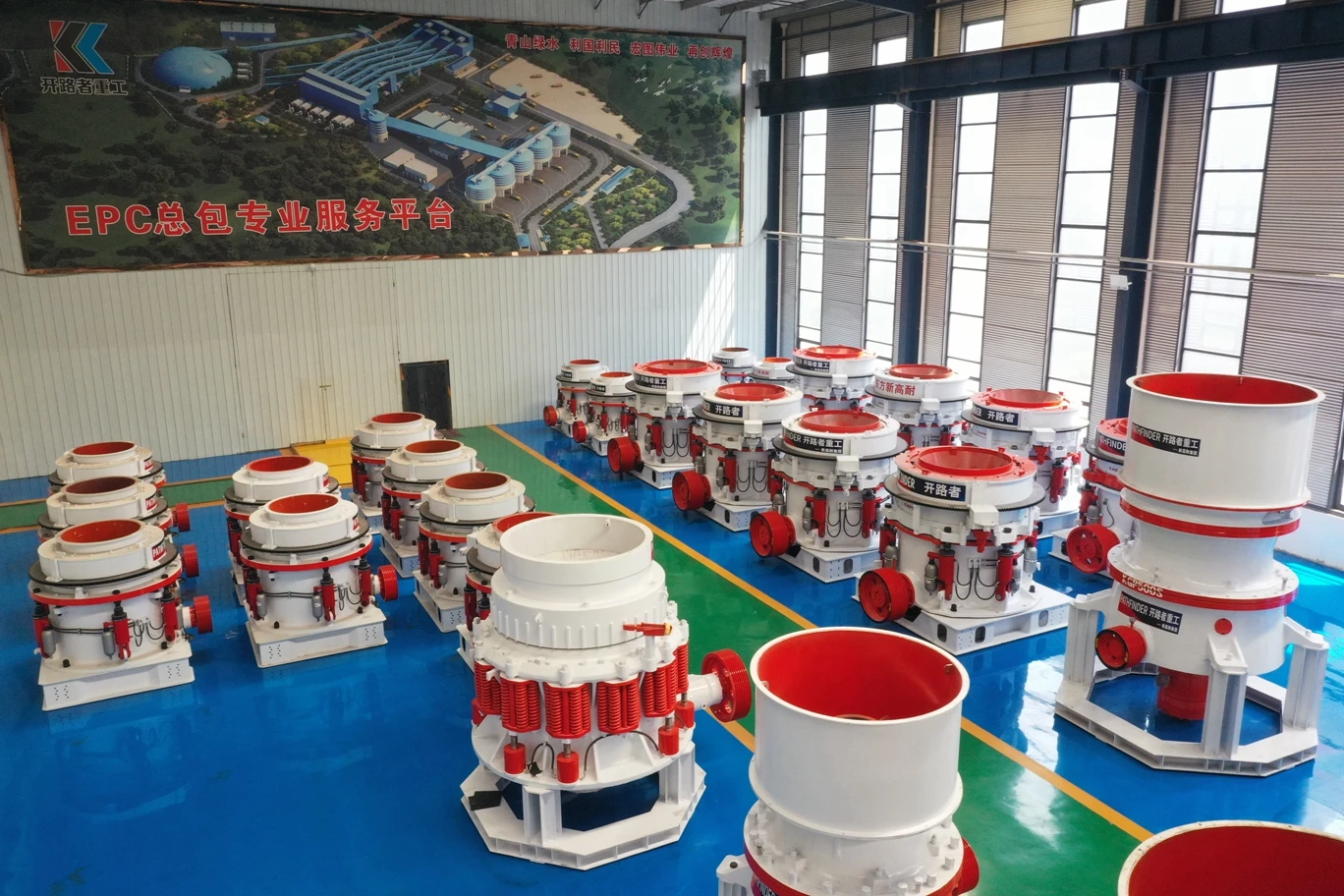

Stone Crushing & Grinding First Brand

We have 3 manufacturing base

Zhengzhou City, Henan Province

Wuzhi City, Henan Province

Xiuwu City, Henan Province

We have 2 brand

Zhengzhou Xingaonai Heavy Industry Machinery Co., Ltd.

(For middle hard stone solutions)

Jiaozuo Pathfinder Heavy Industry

Machinery Co.,Ltd,

(For hard stone solutions)

We have 33 service station worldwide

Give clear solutions within 12 hours

Rush to the site within 24 hours

Xingaonai Group is specialized in R&D and manufacturing of stone crushing, sand making, powder grinding, screening, feeding, conveying, dust collecting and other equipment, we give One-stop Green-Smart-Efficient mining solutions.

Innovation can't just be said in words, it must be turned into a project, and the innovation must be implemented. Today, the company has continuously developed crushing equipment, sand making equipment, mineral processing equipment, supporting equipment, etc. with keen market insight and forward-looking Multi-series, more than 100 models of highly influential products have created more value for enterprises and society.

Our group continuously researches and develops new equipment, adjusts product structure, improves product system, intensively cultivates the core fields of "building crushing, mine crushing, industrial sand making, green building materials, and metal beneficiation", builds three modern equipment production bases, and establishes large-scale equipment The production line continuously improves the production capacity and market influence of the enterprise. In addition to the XGN-Q series hammer crusher, the types of medium and large intelligent crushing equipment are also becoming more and more perfect.

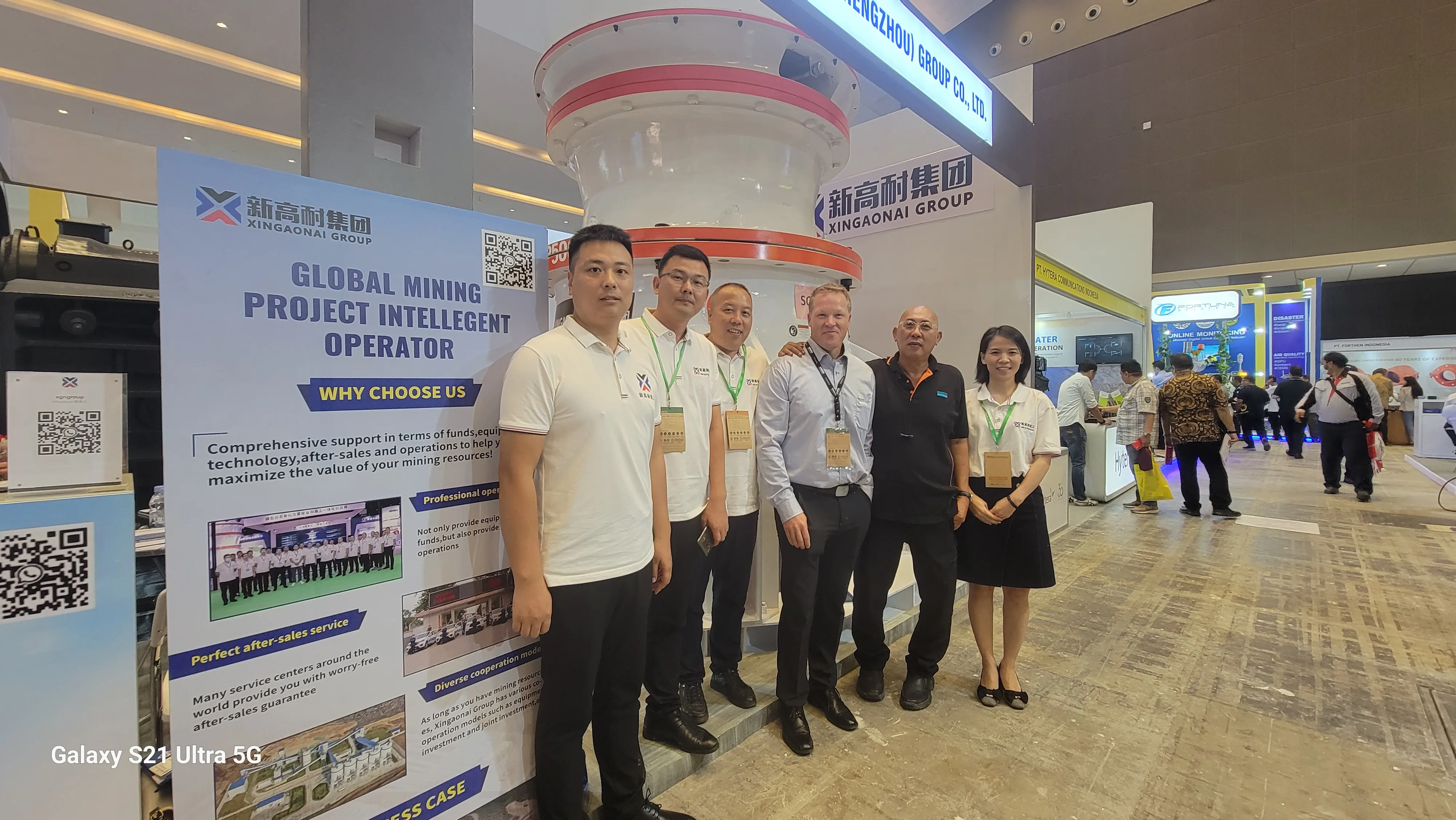

Exhibition

FAQ

A) What is the core competitiveness of the company?

We regard product development as a key task, and develop new products with strong technology, intensive knowledge and good market prospects by tracking demand hot spots and aiming at technological progress in the industry.

B) Product line coverage?

The main business is the equipment required for the production line with an output of 100-6000 tons per hour.

C) What is the main business direction of the product?

Our comprehensive solutions for a range of processes in rock crushing and metal ore.

D) Does the company undertake to build a complete production line?

According to customer needs, we tailor-made recommendations or customization, fast and accurate understanding, special car transportation and distribution, customer inspection and after-sales service, escorting you.

E) Does the company have relevant crusher parts services?

We can provide all kinds of accessories for crushing and screening equipment, with advanced technology, reliable performance and durability, to ensure that customers' needs can be met in a timely and effective manner.