High Energy Saving Ball Mill 900X1800 Pulverizer Grinding Machine for Powder

US $4,300.00-6,200.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Engine, Bearing, motor, Gear

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

0.65-90

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine, Bearing, motor, Gear |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 0.65-90 |

| Place of Origin | Henan, China |

| Brand Name | Fuyuan |

| Dimension(L*W*H) | Depend model |

| Weight | 1500 KG, 1.5 |

| Warranty | 1 Year |

| Product name | Ball mill |

| Keywords | Ball mill 900X1800 |

| Model | 900x1800 |

| Feeding Size | 0-20mm |

| Output size | 0.075-0.89mm |

| Capacity | 0.65-2 |

| Power | 18.5 |

| Color | Customized |

| Spare parts | Supplied |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Farms, Home Use, Retail, Construction works , Energy & Mining, Other |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

| Warranty of core components | 1 Year |

| Condition | New |

| Marketing Type | Hot Product |

Product Detail

High Energy Saving Ball Mill 900X1800 Pulverizer Grinding Machine for Powder

Product Description

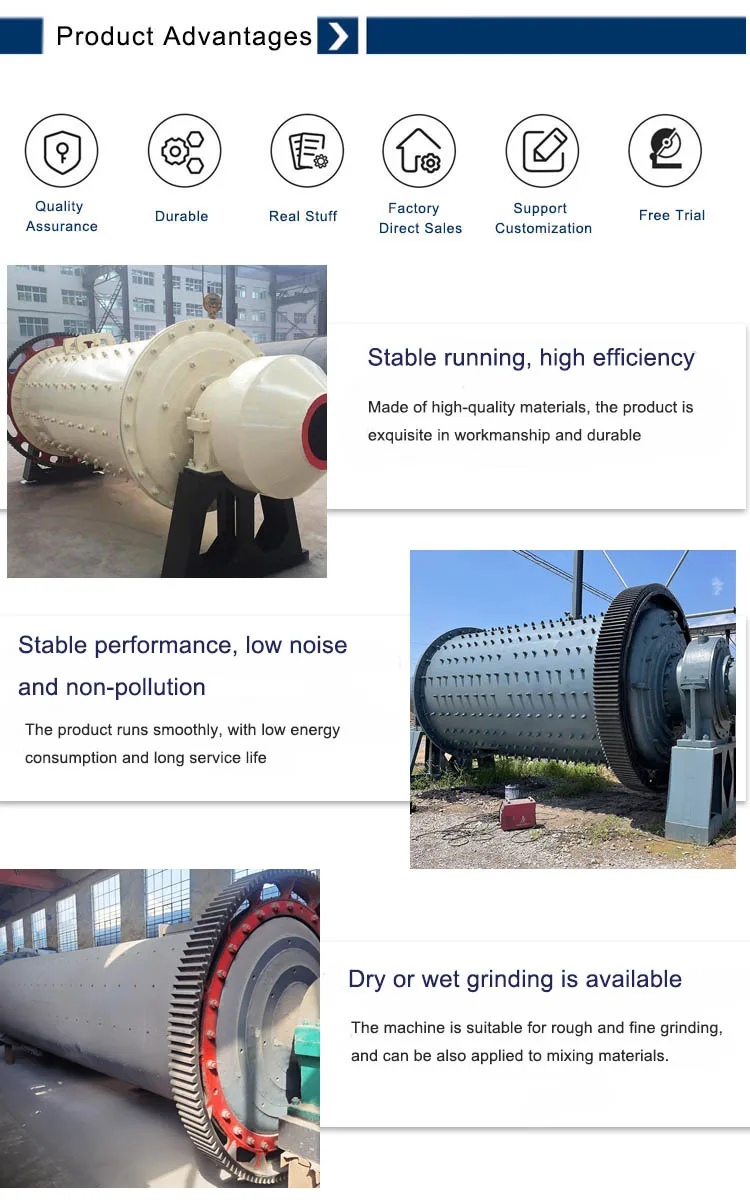

FSY Ball Mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industry. Ball Mills also called grinding mill, ball grinding mill, can grind various ores and other materials either wet or dry, depending on requirements.

Features:

1.The lining can be replaced.

2. Mineral ball mill is an efficient tool for grinding many materials into fine powder.

3.Two ways of grinding: the dry way and the wet way.

4.Ultimate particle size depends entirely on how hard the material you’re grinding is.

5. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Data Sheet

Model | Feeding Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power(kw) | Weight(t) |

900*1800 | ≤20 | 0.075-0.089 | 0.65-2 | 18.5 | 1.5 |

900*3000 | ≤20 | 0.075-0.089 | 1.1-3.5 | 22 | 2.7 |

1200*2400 | ≤25 | 0.075-0.6 | 1.6-5.8 | 37 | 4.6 |

1200*4500 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 5.5 |

1500*3000 | ≤25 | 0.074-0.4 | 2-5 | 75 | 9 |

1500*5700 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 17 |

1830*4500 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 15 |

1830*6400 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 21 |

1830*7000 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 23 |

2100*4500 | ≤25 | 0.074-0.4 | 8-43 | 245 | 24 |

2100*7000 | ≤25 | 0.074-0.4 | 8-48 | 280 | 26 |

2200*4500 | ≤25 | 0.074-0.4 | 9-45 | 280 | 27 |

2200*6500 | ≤25 | 0.074-0.4 | 14-26 | 380 | 35 |

2200*7000 | ≤25 | 0.074-0.4 | 15-28 | 380 | 35 |

2400*3000 | ≤25 | 0.074-0.4 | 30-50 | 245 | 23 |

2400*4500 | ≤25 | 0.074-0.4 | 40-60 | 320 | 30 |

2700*3600 | ≤25 | 0.074-0.4 | 45-80 | 430 | 40 |

2700*4500 | ≤25 | 0.074-0.4 | 50-90 | 430 | 48 |

2700*13000 | ≤25 | 0.074-0.4 | 50-90 | 630 | 60 |

3200*4500 | ≤25 | 0.074-0.4 | - | 800 | 65 |

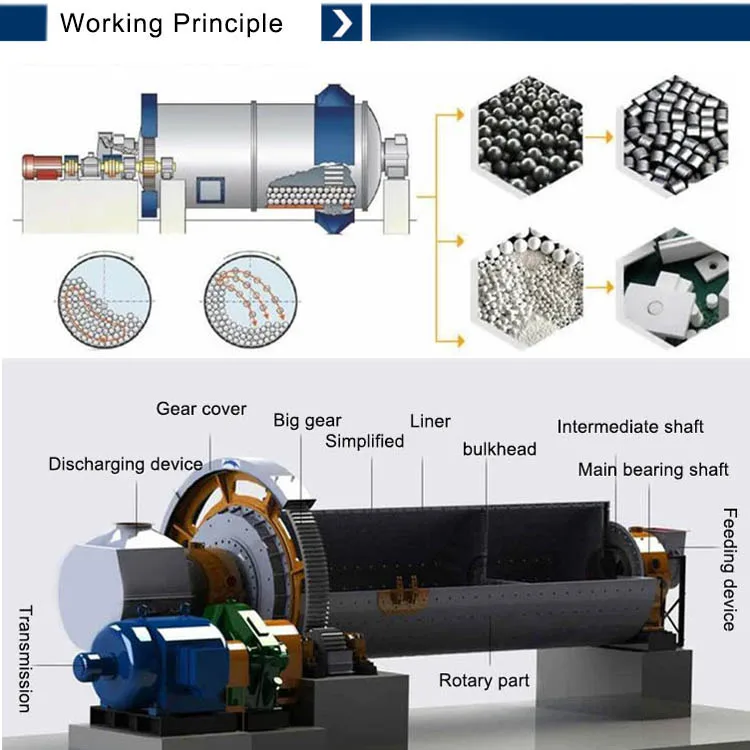

The ball mill is horizontal cylindrical rotation device,driving by brim gearwheel, there are two chambers and grids. Material goes into the first chamber through the feeding inlet, inside the first chamber, there are stage liners and ripple liners as well as steel balls with various kinds.The shell rotates which generates eccentricity, this force brings balls to a certain height and then balls drop down by gravity, which will impact and grind the material. After the primary grinding in the first chamber, material goes into the second chamber through segregate screen, in the second chamber, there are fiat liners and steel balls, after the secondary grinding, material is discharged through the discharge screen.

Product Display

FSY Ball mill is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc . It’s a key equipment for grinding materials after crushing process. It is used to grind kinds of materials into fine powder 20-75 micrometer. Based on discharging type, It could be grate type,overflow type etc.

Customer Site

Company Introduction

Henan Fuyuan Machinery Manufacturing Co., Ltd

Located in High-tech Zone, Zhengzhou City, Henan Province. Our factory was founded in 1984,

covering an area of over 38, 000 square meters and a building area of over 26,000 square meters. There are more than 300 employees, including 5 senior engineers, 23 engineers and more than 60 technicians. After decades of development, the company's appearance is changing with each passing day, and the comprehensive quality of employees has been greatly improved.

Our company has begun to take group scale and form ten series of products:

1.Stone crusher series ( jaw crusher,impact crusher,cone crusher,hammer crusher);

2.Mobile crushing plant series;

3.Sand making machine series;

3.Sand making machine series;

4.Ball mill

5. Wood crusher series.

Packing&Shipping

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% should be paid as down payment; 70% should be paid before delivery.

Q4: How long is the warrenty of your equipments?

A: The warranty period of crusher equipments is 1 year.

Q5: If I need the complete crushing plant can you help us to build it?

A: Yes, we can give you related professional advices .

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.