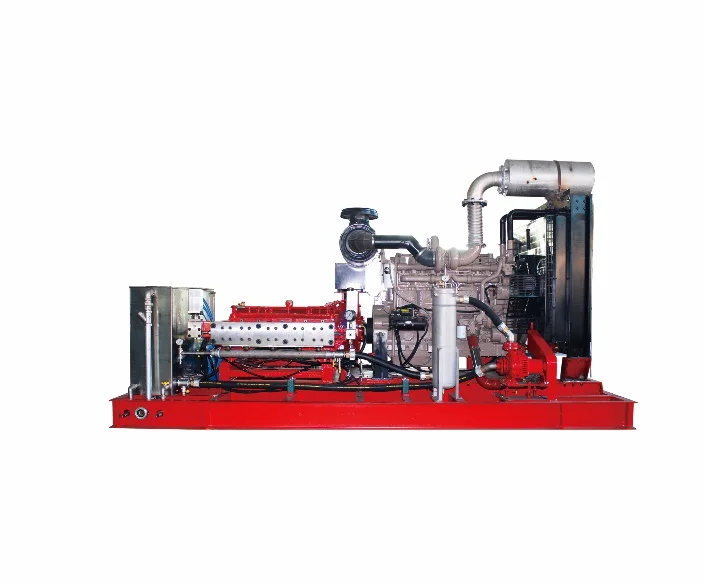

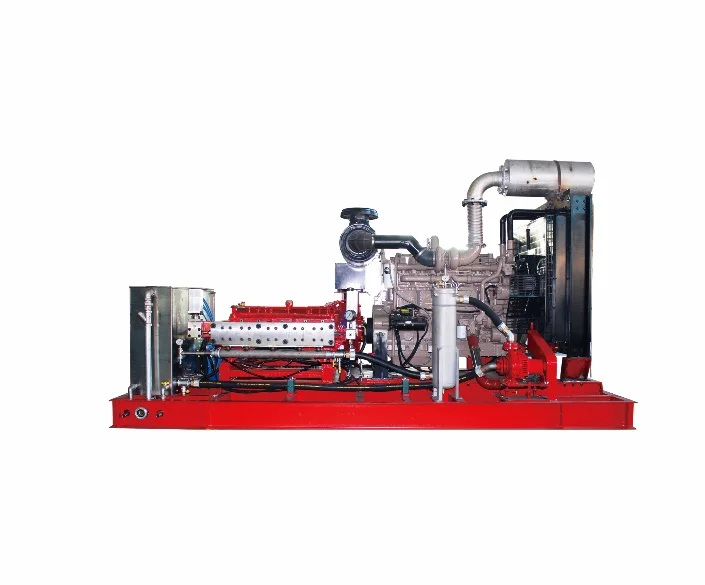

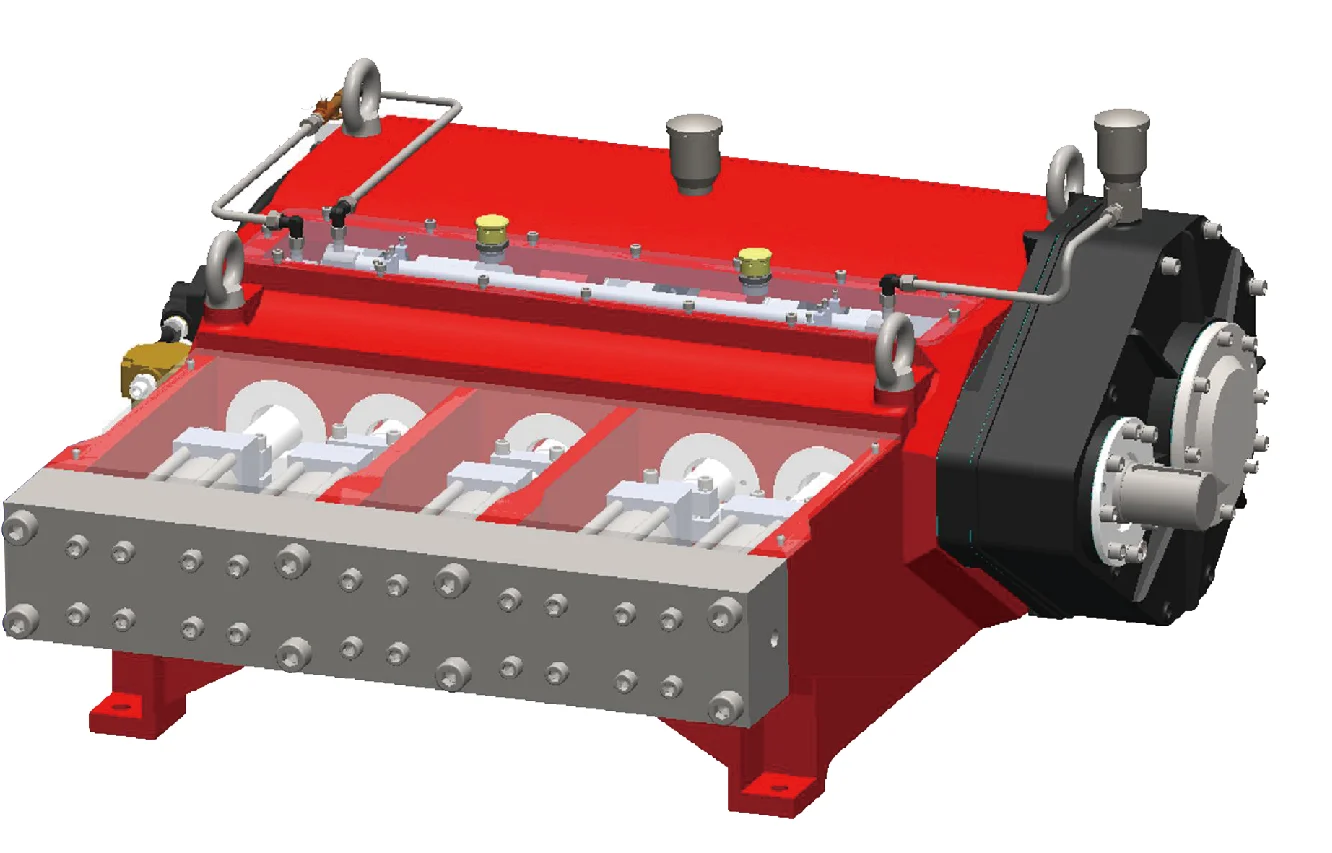

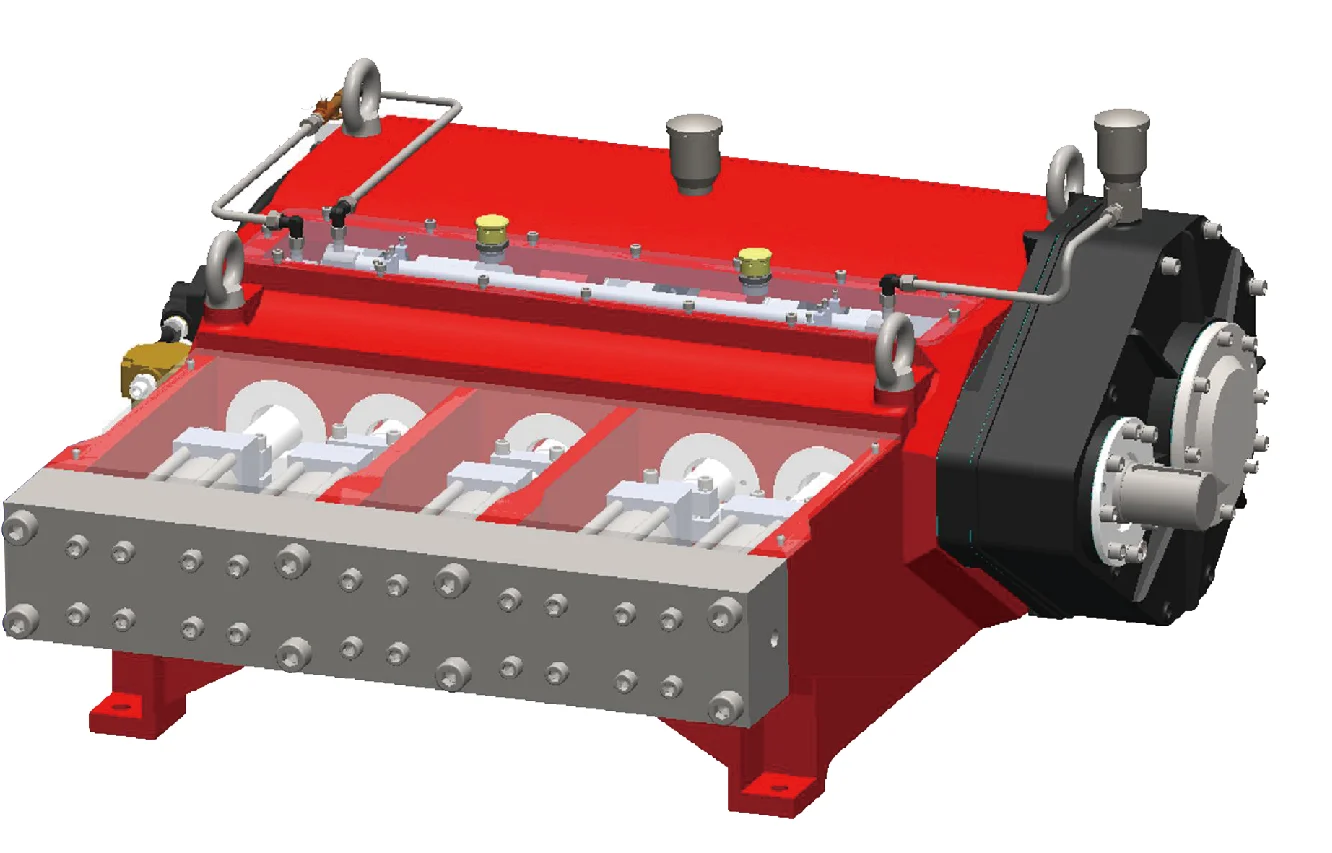

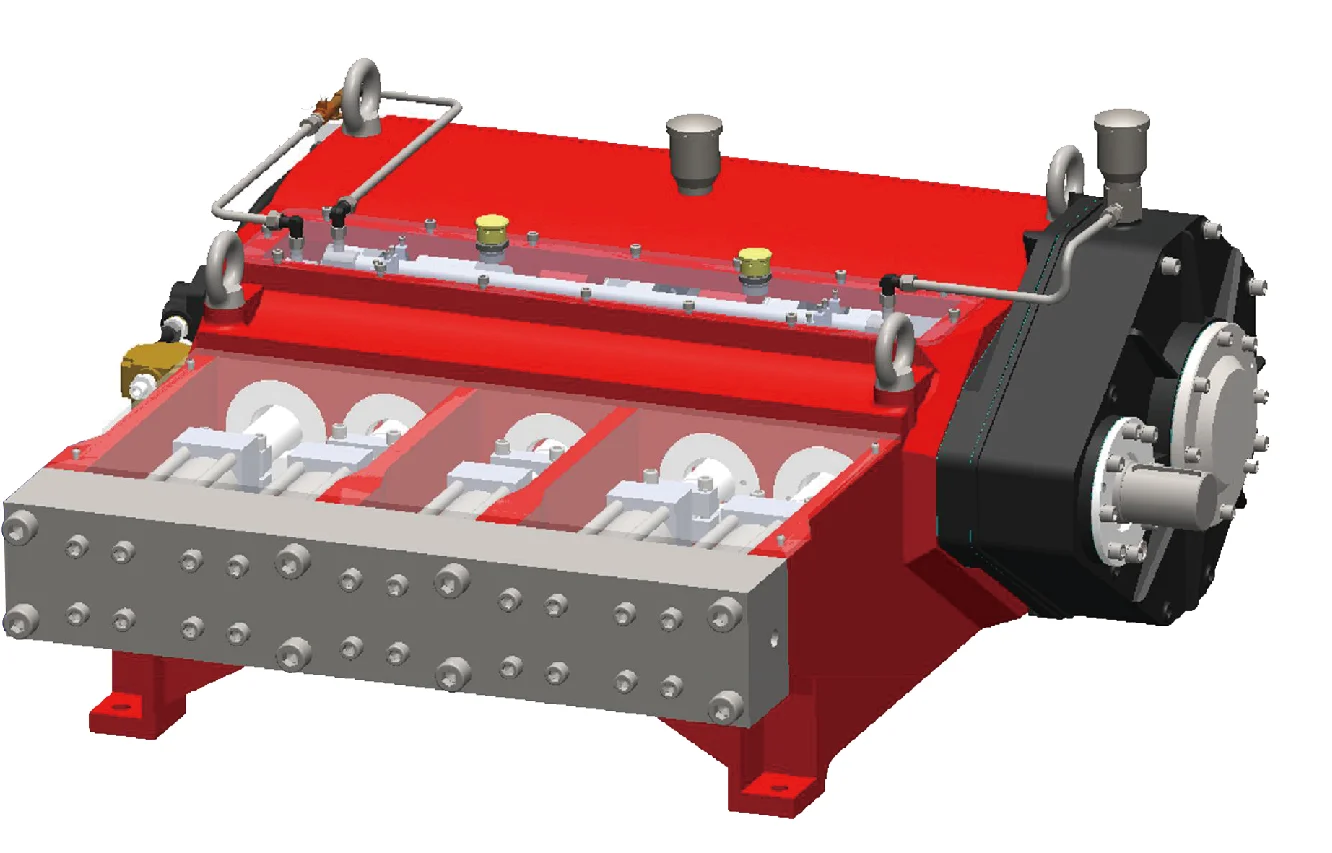

High Pressure Water Jetting System with Power Pump Unit

US $1,500.00-1,600.00 / unit

1 unit(s)Minimum order

machine type:

HIGH PRESSURE CLEANER

condition:

New

place of origin:

Tianjin, China

brand name:

Power

feature:

Rust / Corrosion Inhibitor

power source:

Electric

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| machine type | HIGH PRESSURE CLEANER |

|---|---|

| condition | New |

| place of origin | Tianjin, China |

| brand name | Power |

| feature | Rust / Corrosion Inhibitor |

| power source | Electric |

| use | Descaling / Stripping |

| cleaning process | Vapor Cleaning |

| cleaning type | Industrial Ultrasonic Cleaner |

| industry used | Electronic Industry, Food Processing, Pharmaceutical Cleaning, Beverage Processing |

| material | Metal / Coil |

| power(w) | Other |

| warranty | 1 Year |

| max. pressure | Other |

| weight (kg) | 3000 kg |

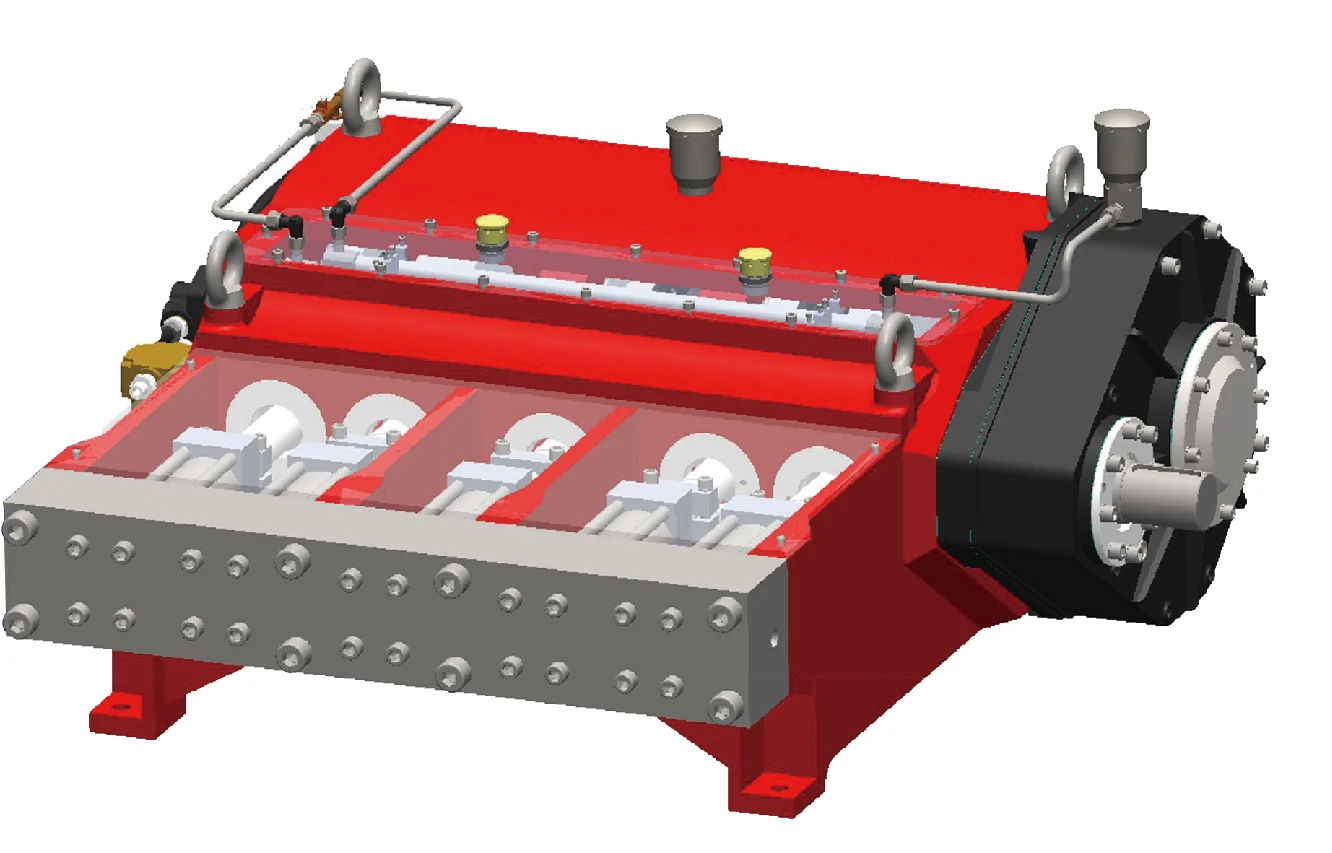

| Product Name | Plunger pump and high pressure cleaning unit |

| Model | PW 505UHP |

| Usage | Heat exchanger, evaporation tank and other types of tank and kettle |

| Main material | Metal |

| Lead time | 45 days |

| Product package list | Unit and packaging accessories |

| Applicable Industries | Manufacturing Plant, Construction works , Energy & Mining |

| Marketing Type | New Product 2020 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Pressure vessel, motor, Bearing, Pump, Gearbox |

| Key Selling Points | Low Maintenance Cost |

Product Detail

Product Description

PW 505

Drive method | Diesel driven | Pump speed | 440rpm |

Pressure (bar) | Diameter of plunger (mm) | Flow (Lpm) | Engine power (KW) |

2800 | 22.2 | 85 | 565 |

2500 | 23.8 | 98 | 565 |

2000 | 25.4 | 111 | 565 |

1400 | 30 | 155 | 565 |

1200 | 32 | 177 | 565 |

1000 | 34 | 200 | 565 |

Technical features:

Using the advanced ultra-high pressure technology of the United States, compact structure, small size, light weight, high energy efficiency, easy to maintain and operate. The engines on board have always been the most advanced systems, with excellent performance in fuel economy, exhaust emissions, operational stability and overall lightweight.

Recommended working conditions:

Descaling of heat exchanger, evaporation tank and other types of tank and kettle, cleaning of pipeline, ship surface, rust removal and paint removal of metal surface, It can be used in powder metallurgy, steel dephosphorization, spunlaced nonwoven and other industries.

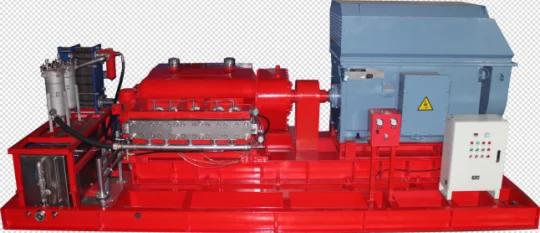

Drive method | Motor drive | Pump speed | 425rpm |

Pressure (bar) | Diameter of plunger (mm) | Flow (Lpm) | Engine power (KW) |

2800 | 22.2 | 82 | 450 |

2500 | 23.8 | 95 | 450 |

2000 | 25.4 | 108 | 450 |

1400 | 30 | 152 | 450 |

1200 | 32 | 174 | 450 |

1000 | 34 | 197 | 450 |

Technical features:

Using the advanced ultra-high pressure technology of the United States, compact structure, small size, light weight, high energy efficiency, easy to maintain and operate. The motor onboard has always become the current advanced frequency conversion system, with excellent performance in energy efficiency, economy, operation stability and control precision.

Recommended working conditions:

Descaling of heat exchanger, evaporation tank and other types of tank and kettle, cleaning of pipeline, ship surface, rust removal and paint removal of metal surface, It can be used in powder metallurgy, steel dephosphorization, spunlaced nonwoven and other industries.

Advantage

According to the application environment and demand can be customized special aircraft, equipment energy saving and environmental protection, stable operation, low failure rate. The same type of pump body can also be equipped with motor drive.

Cleaning machine fault analysis and elimination

Fault performance | Main reason | Solution | |

1 | The power end is abnormal when the pump is running | Water in crankcase causes lubricating oil to emulsify | Change lubricating oil |

Connecting rod bearing wear | Replacement bearing bush | ||

Bearing failure | Bearing replacement | ||

2 | Transmission end middle rod oil leakage | The oil level of lubricating oil is too high | Release a little lubricating oil |

Skeleton oil seal damaged aging | Replace the skeleton oil seal | ||

3 | Pressure gauge display fluctuation (high pressure hose shaking violently) | The valve or spring is broken | Check and replace |

The seal packing or valve of the pump is badly worn | Check and replace | ||

The spool has impurities | Check and remove impurities | ||

Ultra-high pressure pump water supply is insufficient | Troubleshoot mechanical faults according to water pressure | ||

4 | Water pressure alarm (Mechanical failure) | The water tank has no liquid level or the liquid level is very low | Check water supply source |

Y-type filter is blocked | Y-type filter is blocked | ||

Bag filter built-in bag clogging | Clean or replace cloth bags | ||

Low pressure gauge reading above filter | Check pipe pump | ||

The tank float falls off and blocks the outlet | reattach | ||

Water pressure alarm (Circuit failure) | The pressure switch is set too high | Reset 2bar | |

Pressure switch failure | Change the pressure switch | ||

line fault | line repair | ||

5 | High oil temperature alarm (Mechanical failure) | Water in crankcase causes lubricating oil to emulsify | Change lubricating oil |

The lubricating oil grade is incorrect | Replacement of calibration oil | ||

Transmission failure | Check and maintenace | ||

High oil temperature alarm (Circuit failure) | The oil temperature switch is set to a low value | Reset to 75 degrees Celsius | |

The oil temperature switch is damaged | Replace the oil temperature switch | ||

line fault | line repair | ||

6 | Low oil pressure alarm (Mechanical failure) | Gear oil pump damage | Repair or replace |

Gear box free of oil | Add calibration oil to oil level | ||

Low oil pressure alarm (Circuit failure) | The pressure switch is set too high | Reset 1-1.5bar | |

Pressure switch failure | Change the pressure switch | ||

line fault | line repair |

Company Profile

Certifications

Customer Photos

Packing & Delivery

FAQ

1. Who are we?

We are based in Tianjin, China, start from 2017,sell to Domestic Market(80.00%),Eastern Asia(10.00%),Southeast Asia(5.00%),Mid East(5.00%). There are total about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Ultra high pressure pump set,High pressure pump set,Medium pressure pump set,Large remote control robot,Wall climbing remote control robot

4. Why should you buy from us not from other suppliers?

Our company has 50 proprietary intellectual property rights. Our products have been long-term verified by the market, and the total sales volume has exceeded 150 million yuan.

The company has independent R&D strength and standardized management.

5. What services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T;

Language Spoken:English,Hindi