High Pressure YGM138 Fine Grinding Raymond Mill Production Line Raymond Roller Mill Manufacturer

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Gearbox, motor, Gear |

| Type | Raymond Mill, Raymond vertical mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 10-16TPH |

| Place of Origin | Henan, China |

| Brand Name | Hongke |

| Dimension(L*W*H) | Depends on model |

| Weight | 30000 KG |

| Warranty | 1 Year |

| Product name | Raymond roller mill |

| Installation | Engineer's Guide |

| Manufactory | Henan Hongke |

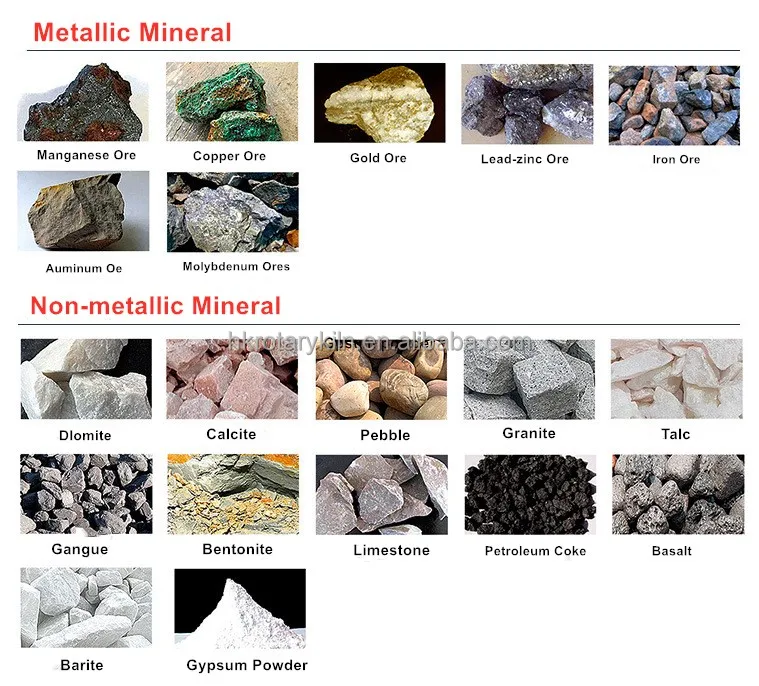

| Grinding material | Limestone,coal,cement, gypsum, etc. |

| Factory visit | Welcome warmly |

| Material | Q235 |

| Advantage | Low Consumption |

| Main Equipment | Hopper, jaw crusher, elevator, pulse dust filter |

| Quality | Industrial Standard |

| Applicable Industries | Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

Secondly, the raw material goes into the grinding chamber of raymond mill machine through the electro-magnetic vibrating feeder at an even rate.

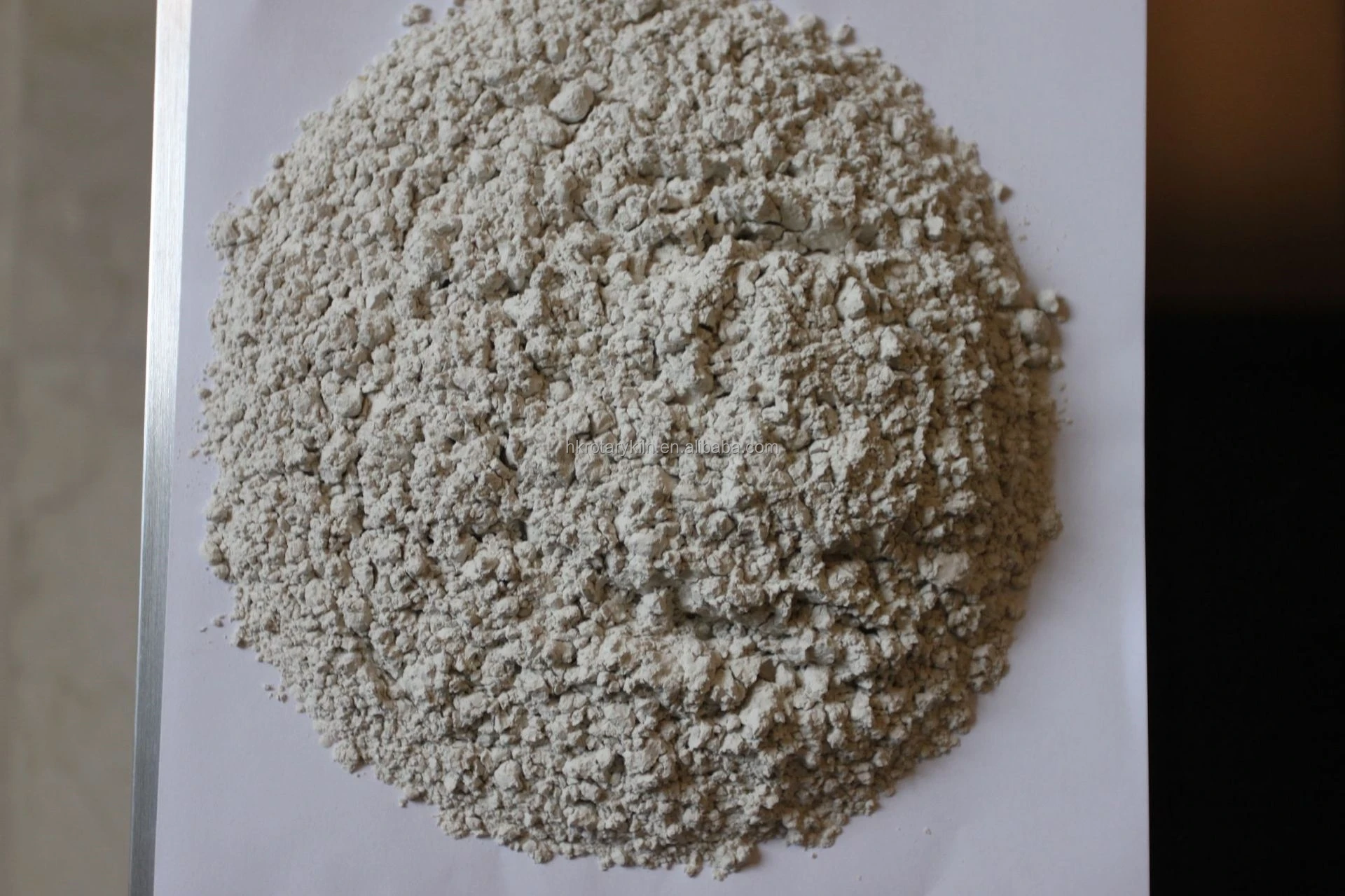

Thirdly, the raw material lifted by the shovel is ground into powderbetween the ring and roller. Fourthly, the powder isblown up to the cyclone collector through the classifier, which will be collected through the discharging valve. The unneeded powder, which cannot go the classifier, will be reground into the needed powder.

2. Compared with other milling plants, its passing ratio achieves 99%, this is what other mill can not reach.

3. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

4. Main parts of the whole plant are made from cast and steel of high quality. The technics is so subtly that insures the

durability of whole plant.

5. The electric control system is centralized controlled, so the automaticity is high, no people are needed in the operating room.

Type | Roller No. | Maximum Feed Size (mm) | Output Size (mm) | Output (t/h) | Motor Power (kw) | Blower Power (kw) | Analysis Machine Power (kw) | Overall Dimension (mm) |

YGM75 | 3 | 15 | 30-325 | 0.4-1.8 | 18.5 | 15 | 2.2 | 4300*3500*5100 |

YGM85 | 3 | 20 | 30-325 | 1-3 | 22 | 18.5 | 2.2 | 5300*4100*5200 |

YGM95 | 3 | 20 | 30-325 | 1.2-4.5 | 18.5 | 15 | 2.2 | 7100*5900*7900 |

YGM130 | 5 | 30 | 30-400 | 3.8-12 | 75 | 175 | 7.5 | 7850*8000*9700 |

YGM138 | 5 | 35 | 30-400 | 6.5-18 | 90 | 110 | 18.5 | 10920*9470*10227 |

YGM175 | 5 | 40 | 30-400 | 11-25 | 160 | 200 | 37 | 12182*8835*9916 |

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical

rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Raw material

3). Capacity ( t/h)

Upon we got your message we shall give you our favorable offer in short time.