High Quality 100mm Ceramic Fiber Blanket 1260 1430c Density Waterproof & Fireproof Thermal Insulation Refractory Applications

Other recommendations for your business

Contact us

Quik Detail

| Grade | HP (High Pure) |

|---|---|

| Application | Liners Of Industrial Furnace |

| Thickness | 10-50mm |

| Width | 610/1220mm |

| Length | 3600/7200/14640mm |

| Chemical Composition | AL2O3+SIO2 |

| Ultimate Strength (≥ MPa) | 0.08-0.12MPa |

| Working Temperature | 1100C/1260C/1360C/1430C |

| Fiber Diameter | 2-5um |

| Shrinkage (1800 ℉, 3h) | 3%(24 Hours) |

| Thermal Conductivity | 0.055-0.180(W.k.m.) |

| Density (kg/m³ ) | 128 |

| Model Number | COM, ST, HP, HA, Zir-Alu, HZ |

| Brand Name | SSJD |

| Place of Origin | Henan, China |

| Product | Ceramic Fiber Blanket |

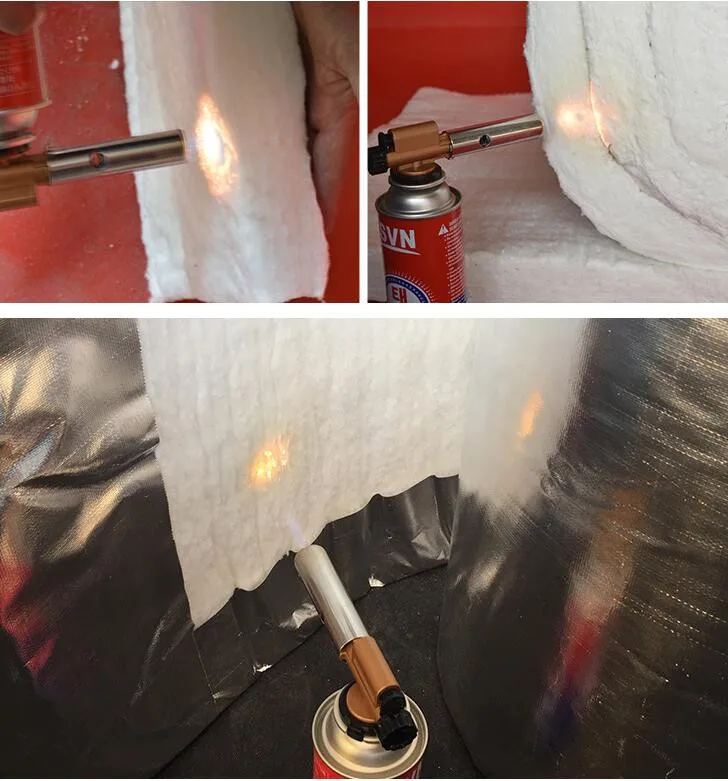

| Function | Refractory & Insulation & Fireproof & Acoustic |

| Raw Materials | Spuned Ceramic Fiber Bulk |

| Density | 96/128/160 Kg/M3 (6/8/10 Lb/FT3) |

| Category | Ceramic Fiber |

| Certificate | CE&ISO&TUV |

| Application of ceramic fiber blanket | Construction, High Temperature Kilns, Pipelines |

| Feature | Heat Resistant Insulation |

| Color | Pure White |

| Package | Plastic Bag Inside + Carbon |

Product Detail

1. Grade: Common , Standard , High pure , High aluminum , High zirconium ,

2. Size: 7200 mm*610 mm*50 mm

Length: 12000-60000 mm(12000,15000,20000,30000,40000,60000)

Width: 610-1220 mm(610,1220)Thickness: 0.5-5 mm(0.5,1,2,3,4,5)

Product Name | 1430 C Ceramic Fiber Blanket Aluminum Silicate Wool for Refractory Applications |

Material | Refractory ceramic fiber wool |

Color | white |

Classify temperature | 1100℃ 1260℃ 1360℃ 1430℃ 1600℃ |

Character 1 | Low thermal conductivity and capacity , Good tensile strength and Sound-absorbing |

Character 2 | Excellent thermal insulation and fireproof , easy to installation and good machining |

Application | 1. Ceramic industry: Kiln car insulation and seal, contious and batch kiln. 2. Steel industry: Heat treating and annealing furnace, furnace lining and seals, reheating furnace and ladle covers, furnace hot face repairs, soaking hit covers and repairs. 3. Reefing and petrochemical: reformer and pyrolisis lining, tube seals, gaskets and expansion joints, high temperature pipe, duct and turbine insulation. Crude oil heater lining. 4. Power generation: Boiler insulation, expansion seals and covers insulation. 5. Others: insulation of commercial dryers and ovens, refractory materials, glass furnace insulation, fire protection. |

Data | Shringkage on heating (%) 950CX24h ≤-3 Thermal Conductivity (w/m.k)(128kg/m3) ≤0.153 (mean temperature:500C) Tensile strength:(128 kg/m3) MPa: 0.08-0.12 Slag content (diameter ≥0.212 mm): ≤ 25% |

Packing Details:

1.Plastic bag inside ,woven bag outside. 2 rolls/ bag. 620 rolls/1*40HQ.

2. Plastic bag inside, carton outside. 1 roll/carton. 525 cartons/1*40 HQ3. Wooden pallet. 20 cartons/pallet, 21 pallet/1*40 HQ.

4. As customer's requirement.

Delivery Details : According to distance, we can work out the best transport routine.