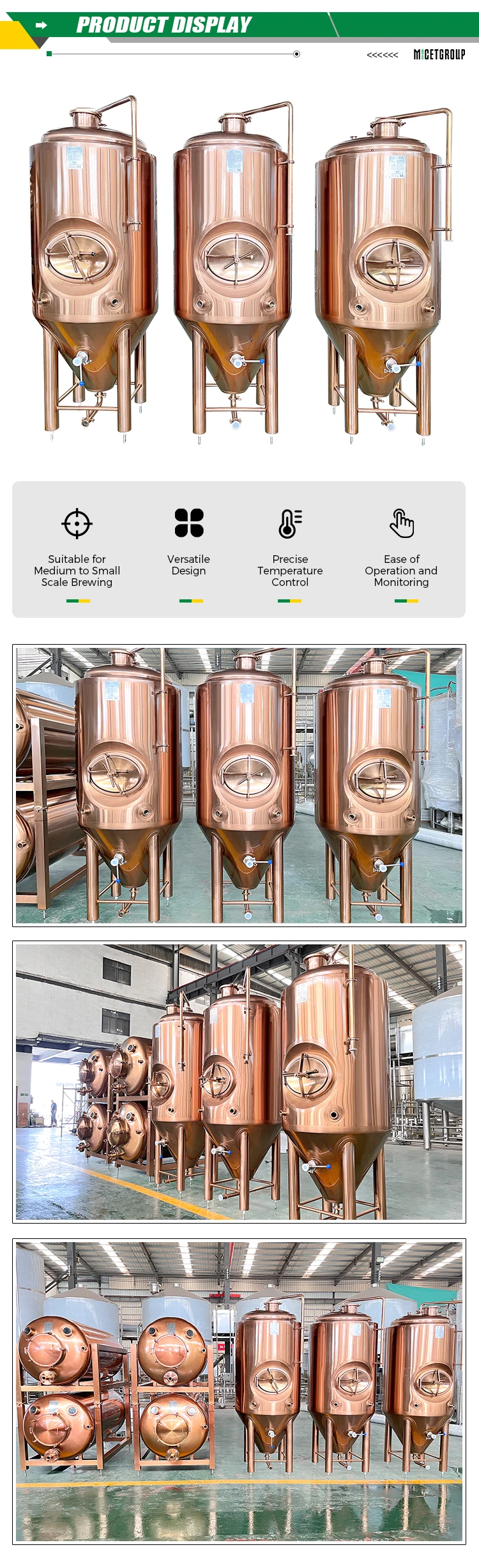

High Quality 500l Red Copper Brewing Equipment Fermentation Tank Conical Fermenter With Glycol Jacket

US $2,000.00-2,500.00 / set

1 set(s)Minimum order

processing:

Fermenting Equipment

place of origin:

Shandong, China

brand name:

Micet

processing types:

Beer

voltage:

Customized

power(w):

Customized

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| brand name | Micet |

| processing types | Beer |

| voltage | Customized |

| power(w) | Customized |

| dimension(l*w*h) | Customized |

| weight | 2000 |

| warranty | 5 years |

| Machinery Capacity | 50l, 100L, 200L, 300L, 400L, 500L |

| machinery test report | Provided |

| core components | motor, Pump, Pressure vessel, PLC |

| key selling points | Energy saving |

| video outgoing-inspection | Provided |

| Product Name | 500L Beer Fermenter |

| Function | Liquild Fermentation |

| Keywords | Craft Beer Brewery |

| Material | Stainless Steel 304 |

| Capacity | 500L |

| Heating way | Steam Electric Gas Heating |

| Cooling way | Dimple Jacket Plate |

| Color | red copper |

| Brand | Micet |

| MOQ | 1 Set |

Product Detail

High quality 500L Red copper brewing equipment fermentation tank conical fermenter with glycol jacket

The fermentation tank is a container for microorganisms to carry out the fermentation process, and it provides a place suitable for life activities and metabolism for microorganisms. To adapt to the use of different sizes of breweries, Micet produced a variety of sizes and specifications of fermentation tanks. Customers can choose the most suitable fermentation tank according to their needs. Because there are many types of beverages that need to be fermented, there are also many types of fermenters.

Effective volume | 5BBL | 10BBL | 15BBL | 20BBL | 25BBL | 30BBL | 40BBL | 50BBL | |||||||

Total volume | 6.25BBL | 12.5BBL | 18.75BBL | 25BBL | 31.25BBL | 37.5BBL | 50BBL | 62.5BBL | |||||||

Size | 960*2050mm | 1160*2500mm | 1260*2800mm | 1460*3050mm | 1700*3350mm | 1750*3450mm | 1800*3550mm | 1900*4250mm | |||||||

Material | SUS304/SUS316 | ||||||||||||||

Control system | PLC Siemens or PID Schneider/ABB brand | ||||||||||||||

Work pressure | Internal Shell 0.2MPa; cooling jacket 0.3Mpa | ||||||||||||||

Design pressure | Internal Shell 0.3MPa; cooling jacket 0.5Mpa | ||||||||||||||

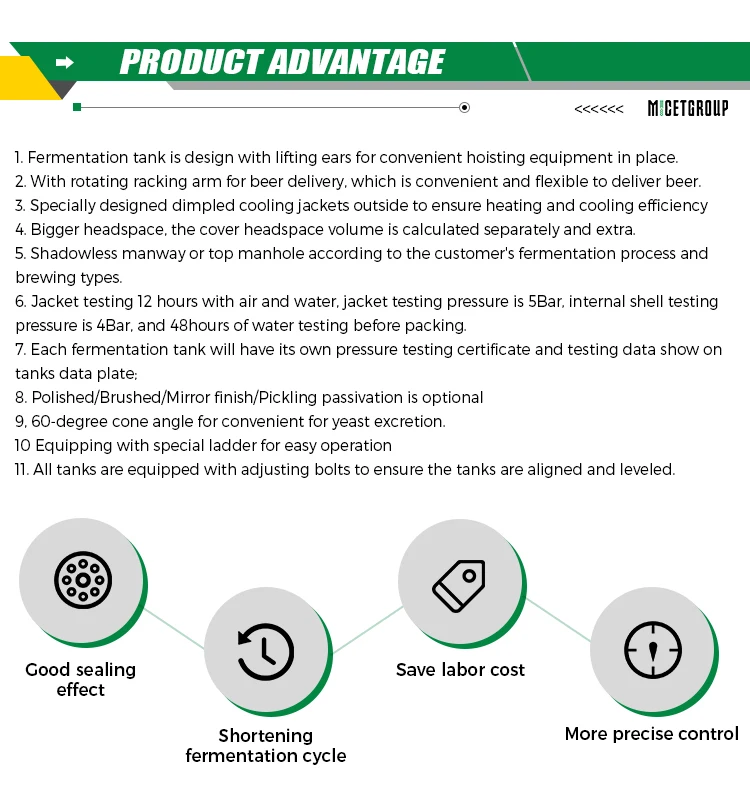

1. Fermentation tank is design with lifting ears for convenient hoisting equipment in place.

2. With rotating racking arm for beer delivery, which is convenient and flexible to deliver beer.

3. Specially designed dimpled cooling jackets outside to ensure heating and cooling efficiency

4. Bigger headspace, the cover headspace volume is calculated separately and extra.

5. Shadowless manway or top manhole according to the customer's fermentation process and brewing types.

6. Jacket testing 12 hours with air and water, jacket testing pressure is 5Bar, internal shell testing pressure is 4Bar, and 48hours of water testing before packing.

7. Each fermentation tank will have its own pressure testing certificate and testing data show on tanks data plate;

8. Polished/Brushed/Mirror finish/Pickling passivation is optional

9, 60-degree cone angle for convenient for yeast excretion.

10 Equipping with special ladder for easy operation

11. All tanks are equipped with adjusting bolts to ensure the tanks are aligned and leveled.

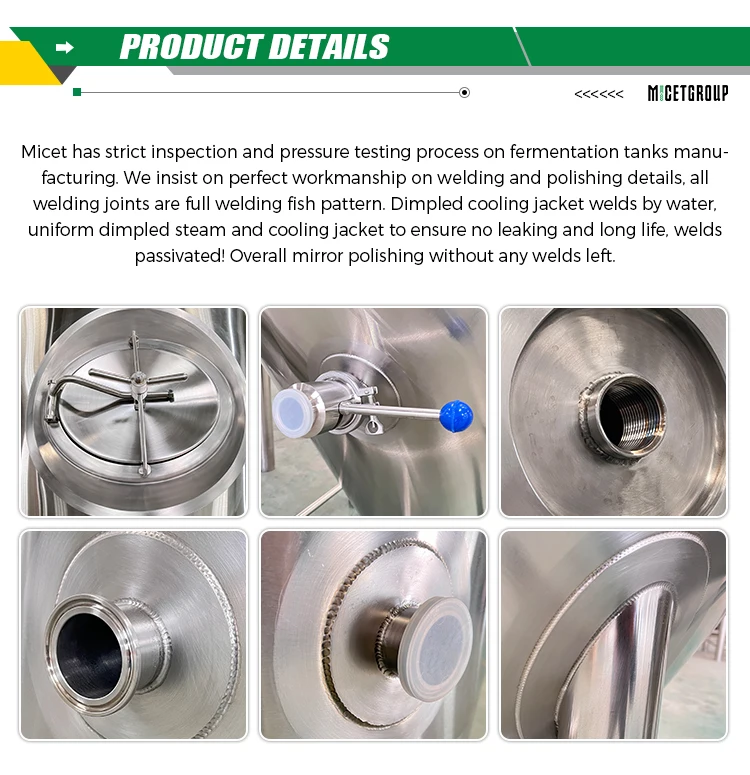

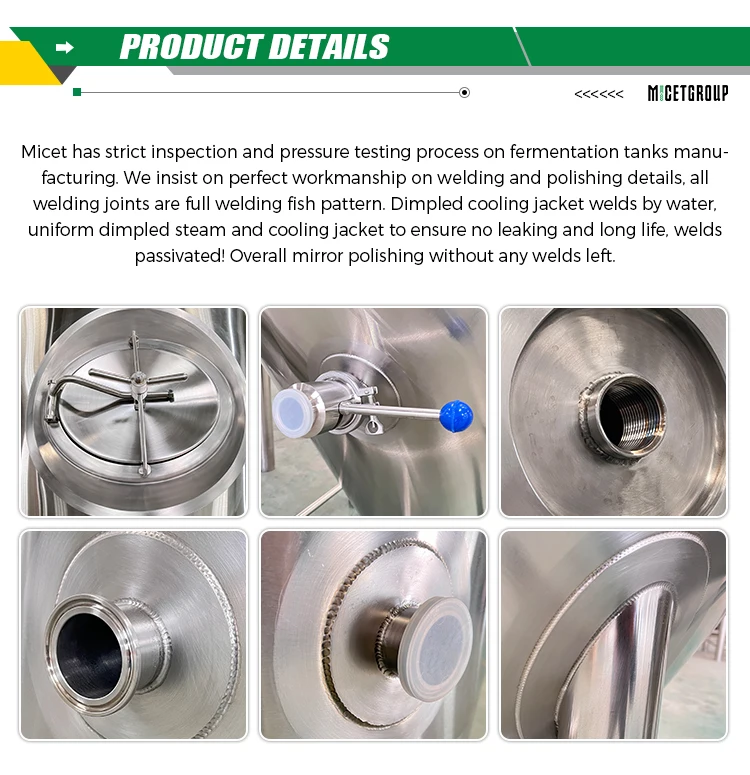

Micet has strict inspection and pressure testing process on fermentation tanks manufacturing. We insist on perfect workmanship on welding and polishing details, all welding joints are full welding fish pattern. Dimpled cooling jacket welds by water, uniform dimpled steam and cooling jacket to ensure no leaking and long life, welds passivated! Overall mirror polishing without any welds left.

LCL Shipping

1.The equipment will be covered by plastic film, then packed inside of wooden case!

2. Different parts will be packed in different wooden box for customers to find easily.

3. All tanks ports with a plastic cover to prevent dust.

4. The tanks and wooden case will be fixed inside the container by bolts and steel wires.

3. All tanks ports with a plastic cover to prevent dust.

4. The tanks and wooden case will be fixed inside the container by bolts and steel wires.

FCL shipping

1. Shipping department will work out the checking list with all that will be shipped.

2. Different parts will be packed in different wooden box for customers to find easily

3. All tanks ports with a plastic cover to prevent dust;

4.Tanks on cradle must be secured with bolts.

5. The cradle and tanks will be fixed inside the container by bolts and steel wires.

6. After shipping, we will have the completed loading pictures and checking list with all parts pictures provided to customers.

How you can guarantee your equipment quality?

Our quality, all our raw materials used are stainless steel 304 or 316 material, the plate is all perfect 3mm and 2mm, some manufacturers with low prices, but they are 2.7mm. Another importantly is all of our workers are from the South of China, which is famous for good workmanship.

Can you customize products according to customer requirements?

Yes, we support product customization.We are a factory, so you can tell our sales manager about the product requirements, and our engineers will design your own drawings for you.

How long does it take to get equipment?

Normally our production circle is from 30-50 working days depending on the order.

For the time being, from the day we get your deposit to the delivery we are looking at 90-150 days at your door delivery. Our leadtime will vary depending on our factory workload but we do like to keep honest leadtimes so there is no surprises except getting the equipment earlier that what it was suppose to.