High Quality Engineering Veneer Slitter and Rewinder pp Film Melamine Foil New Automatic Slitting Machine

US $8,000.00-12,000.00 / set

1 set(s)Minimum order

warranty:

1 Year

type:

Other

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

motor

application:

Machinery & Hardware

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| warranty | 1 Year |

|---|---|

| type | Other |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | motor |

| application | Machinery & Hardware |

| Packaging Type | Film |

| Packaging Material | Plastic, paper, PVC |

| automatic grade | Automatic |

| driven type | Electric |

| Voltage | 380V 50Hz or Customized |

| power | 3kW |

| place of origin | Guangdong, China |

| brand name | Cambery |

| dimension(l*w*h) | Approx. 2460*1400*1250 mm |

| key selling points | Automatic |

| Product name | Packing Machine |

| Function | High Effieciency |

| After-sales Service Provided | Engineers |

| Name | Bopp Slitting Rewinding Machine |

| Keyword | Packaging System |

| Usage | Widely Used |

| Suitable for | Park Warehouse Express Bag Sealing |

| Type | Vertical Hydraulic Baling Press Machine |

| Packing material | Wooden Case Packing |

| Machine type | Automatic Vertical Packing Machine |

| Applicable Industries | Manufacturing Plant |

| Showroom Location | None |

| Warranty of core components | 1 Year |

| Condition | New |

| Weight | 1500 KG |

Product Detail

提示信息

Subtitle/CC

Speed

Quality

Audio Track

Speed

Subtitle/CC

Audio Track

Quality

PRODUCT INFORMATION

TECHNICAL CHARACTERISTICS

Overall Size | Approx. 2460*1400*1250 mm |

Weight | Approx. 1500 kg |

Rewinding Speed | Up to 120 m/min |

Total Power | 3 kW |

Power Supply | 380V 50Hz or customized |

Air Pressure | 6 bar |

Max. Film Width | Up to 1300 mm |

Min. Slitting Width | 20mm |

Rewind Shaft | 3in. Expansion Shaft or customized |

Max. Unwinding Diameter | 400mm |

Rewind Shaft | 3in. Expansion Shaft or customized |

Max. Rewinding Diameter | 400mm |

Driving System | INVT motor drive |

Tension Control System | 10kg Magnetic Powder Brake for Unwind Shaft; 5kg Magnetic Powder Brake for Rewind Shafts; |

EPC System | Photo Electric Sensor |

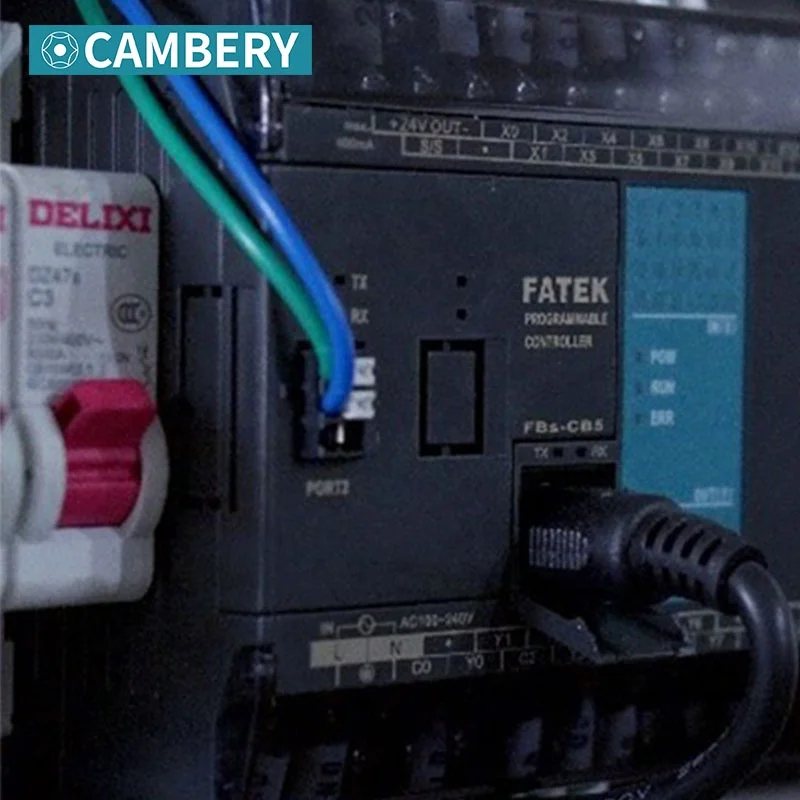

Electronic components | Schneider®, FATEK® or equivalent. |

Pneumatic components | AirTac® or equivalent |

Cutting System | Razor Blade, 12 sets |

DETAILS DISPLAY

STABLE FRAMEWORK

Machine frame structure manufactured forming a rigid, steady body. Strictly manufacture with the procedure of cutting, good welding, CNC machining, tempering and painting. Then, precisely assembling of all elements.

Centralized Control System

● 7 inch touch screen for user-friendly

● Stable Tension control system

● Hazel-Free EPC system

● Stable Tension control system

● Hazel-Free EPC system

Multi-Precise Blades

● Multiple precise blades could slit maximum 12 rolls in one time.

● Adjustable Slitting among 30-1200mm wide.

● Adjustable Slitting among 30-1200mm wide.

TENSION CONTROL SYSTEM

● Applicable for slitting of paper, thin-films, metal foils.

● Material’s tension will be changed with the variation of diameter of the reel in the process of unwinding, central guiding and rewinding.

● Keeping the rolling in a constant tension to make sure the perfect slitting.

● Material’s tension will be changed with the variation of diameter of the reel in the process of unwinding, central guiding and rewinding.

● Keeping the rolling in a constant tension to make sure the perfect slitting.

EDGE POSITION CONTROL SYSTEM

● Fully automatic edge position control.

● Rewind speed up to 60 m/min.

● Heavy-duty actuator.

● Rewind speed up to 60 m/min.

● Heavy-duty actuator.

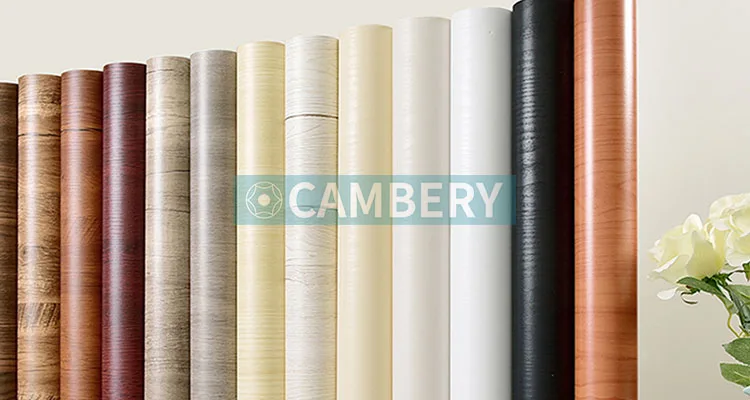

APPLICATION

High speed and quality unwinding and rewinding the roll form material like PVC foil, veneer, paper and slitting into the specific width.

HOT SALE

COMPANY OVERVIEW

WELCOME TO VISIT US

Cooperation with up to 50 countries around the world.

Cooperation with up to 50 countries around the world.

OUR CERTIFICATION

FAQ

Q1. Warranty

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.