Hot Sale Round Blade Food Cutting Blades Frozen Meat Cutting Blade High Quality and Low Price

US $1.50-2.00 / piece

10 piece(s)Minimum order

place of origin:

China

warranty:

3 months

video outgoing-inspection:

Provided

machinery test report:

Not Available

core components:

blade

type:

Slaughter production line knives

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | China |

|---|---|

| warranty | 3 months |

| video outgoing-inspection | Provided |

| machinery test report | Not Available |

| core components | blade |

| type | Slaughter production line knives |

| brand name | REN Xing Blade |

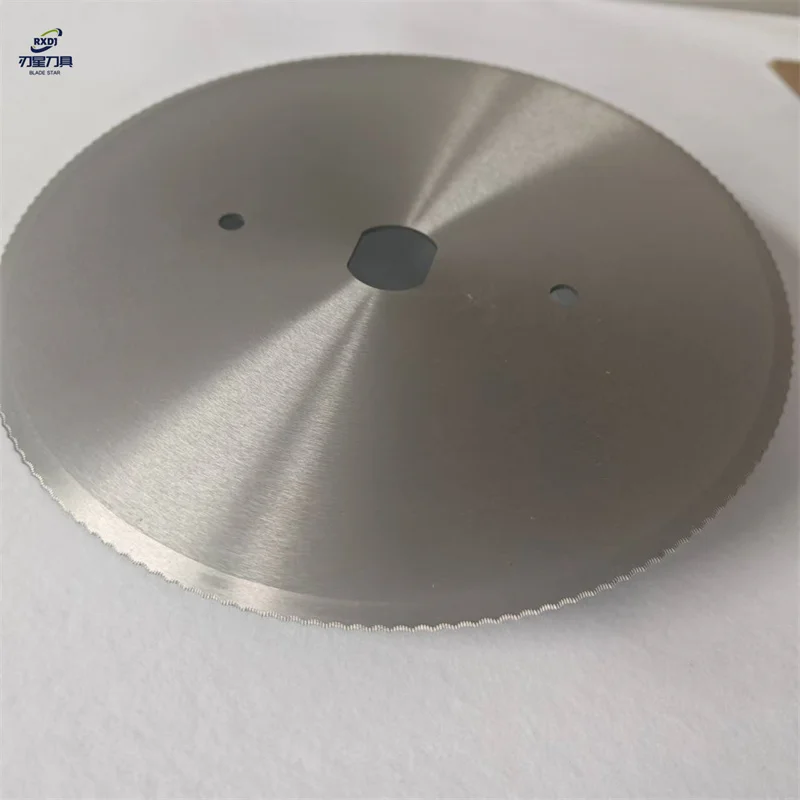

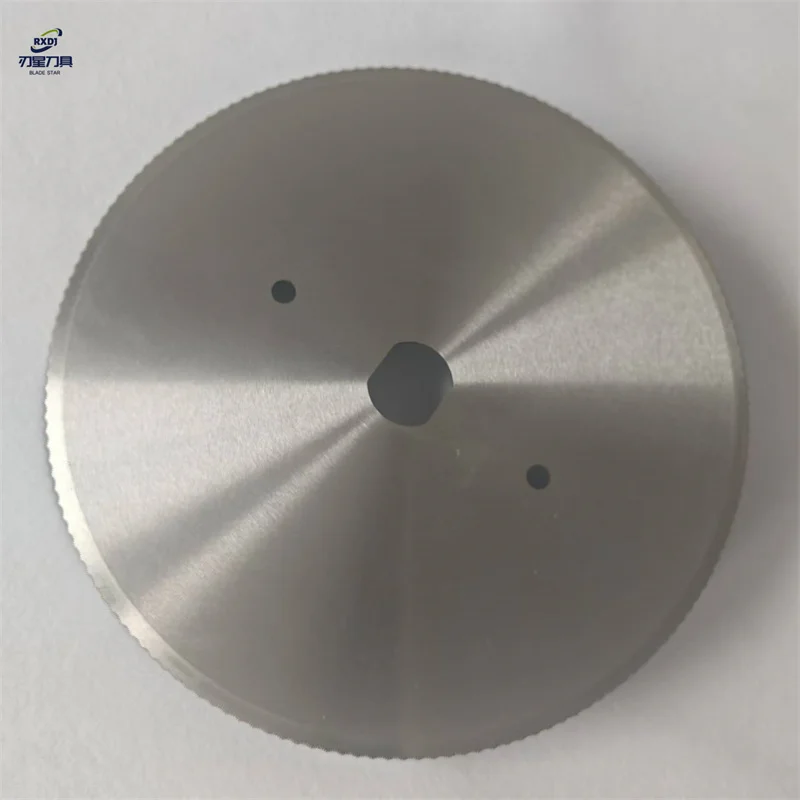

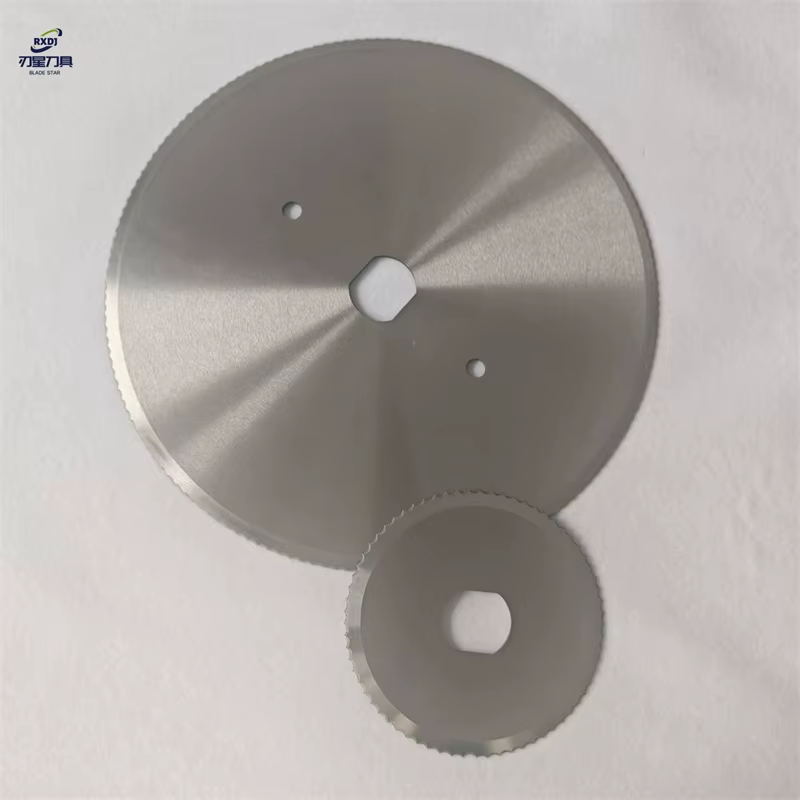

| Product name | round blade |

| Condition | New |

| Applicable Industries | hotels,Food & Beverage Factory,Food Shop,Other |

| Showroom Location | None |

| Warranty of core components | Not Available |

| Marketing Type | New Product 2024 |

Product Detail

Product descriptions from the supplier

Our company is called Renxing Blade Machinery Company.We are a professional manufacturer in industrial blades with over 20years experiences.

We provide Doner kebab knives, Chicken/ Seafood/ Meat/ Vegetable cutting knives for food processing industry. Poultry Processing Standard blades for MEYN,STORK, MAREL, LINCO ....

Customization are all available.

Feel free to send us inquiry.

Customization are all available.

Feel free to send us inquiry.

Products Description

Specification | ||

Product name | Poultry slaughtering, packaging knives | |

Size | customized | |

Material | Stianless Steel 420 or customized | |

Hardness | 52-60 HRC | |

Application | Poultry cutting / Fish cutting | |

MOQ | 50 pcs | |

OEM | Available | |

After Warranty Service | Online support | |

Local Service Location | None | |

After sales Service Provided | Online support | |

Flatness | < 0.1 mm | |

Surface Treatment | Mirror grinding | |

Introduction to Poultry slaughtering, packaging knives

Production and sales of lamb slicer blades, meat chopping and mixing blades, food stainless steel

blades, food meat chopping and mixing blades, food hinge meat blades, food vegetable cutting blades, lamb slicer blades, stainless

steel vegetable cutting blades, fruit shredding blades, food ham sausage chopping and mixing blades, food fruit and vegetable

slicing and cutting blades, food slicer blades, food round blades, frozen meat slicer blades, vegetable cutting blades, ham

cutting blades and other food machinery blades, various food industry blades, stainless steel food blade products.

Some food machinery products are available in stock, while non-standard food machinery products can be processed and customized

according to customer provided product drawings, specifications, blade materials, hardness values, and other requirements.

1.When not using food packaging blades, the blades should be wiped clean and hung vertically on a dry shelf. The food packaging

cutting blades should not be placed flat, as it may cause deformation of the cutting blades.

2. The cutting edge of the food packaging blade is extremely hard and sharp, and it is prohibited to collide with each other or

falloff the ground. It must be handled with care.

3. When operating, it is necessary to wear protective covers, work gloves, safety helmets, safety shoes, protective goggles, and

other safety measures.

4. Before installing the food packaging cutting blade, it is necessary to confirm the performance and purpose of the machinery

to ensure that the packaging cutting direction indicated by the food packaging cutting blade is consistent with the rotation

direction of the blade. It is strictly prohibited to install in the opposite direction. Installing in the wrong direction may

cause damage to the blades, preventing accidents.

5. When installing the food packaging cutting blade, it is necessary to first check whether there are cracks on the food

packaging cutting blade.

blades, food meat chopping and mixing blades, food hinge meat blades, food vegetable cutting blades, lamb slicer blades, stainless

steel vegetable cutting blades, fruit shredding blades, food ham sausage chopping and mixing blades, food fruit and vegetable

slicing and cutting blades, food slicer blades, food round blades, frozen meat slicer blades, vegetable cutting blades, ham

cutting blades and other food machinery blades, various food industry blades, stainless steel food blade products.

Some food machinery products are available in stock, while non-standard food machinery products can be processed and customized

according to customer provided product drawings, specifications, blade materials, hardness values, and other requirements.

1.When not using food packaging blades, the blades should be wiped clean and hung vertically on a dry shelf. The food packaging

cutting blades should not be placed flat, as it may cause deformation of the cutting blades.

2. The cutting edge of the food packaging blade is extremely hard and sharp, and it is prohibited to collide with each other or

falloff the ground. It must be handled with care.

3. When operating, it is necessary to wear protective covers, work gloves, safety helmets, safety shoes, protective goggles, and

other safety measures.

4. Before installing the food packaging cutting blade, it is necessary to confirm the performance and purpose of the machinery

to ensure that the packaging cutting direction indicated by the food packaging cutting blade is consistent with the rotation

direction of the blade. It is strictly prohibited to install in the opposite direction. Installing in the wrong direction may

cause damage to the blades, preventing accidents.

5. When installing the food packaging cutting blade, it is necessary to first check whether there are cracks on the food

packaging cutting blade.

Details Images

Recommend Products

Certifications

Why Choose Us

FAQ

Q: What Steel Grades do you use to manufacture Industrial Blades?

A: We select appropriate Steel Grades for your applications. Popular materials for example:

Food processing blades – Stainless steel 420, 440A and 440C.

Plastic recycling blades and wood-working blades – D2/SKD11, DC53, A8, etc.

Paper making, printing and slitting blades – Steel 52100, D2/SKD11, SS, HSS (High Speed Steel) and Tungsten Carbide.

Q: How long do your machine knives work before re-sharpening?

A: Up to 50% longer than competitors according to feedbacks from our dear customers. Please contact us. Our expert team will

assess your cutting requirements and working conditions to help you find the longer-life solution.

Q: How do you guarantee your quality?

A: All operations from original drawing to final product are strictly controlled and traceable. Never a defective product will be

delivered to our customer.

Q: How long does it take to manufacture a machine knife to customized specification?

A: Normally 35 to 45 days. We can stock special knives for you. Please contact us to discuss your requirements.

Q: What is you payment terms?

A: Payment via Alibaba, TT, L/C are all acceptable.

A: We select appropriate Steel Grades for your applications. Popular materials for example:

Food processing blades – Stainless steel 420, 440A and 440C.

Plastic recycling blades and wood-working blades – D2/SKD11, DC53, A8, etc.

Paper making, printing and slitting blades – Steel 52100, D2/SKD11, SS, HSS (High Speed Steel) and Tungsten Carbide.

Q: How long do your machine knives work before re-sharpening?

A: Up to 50% longer than competitors according to feedbacks from our dear customers. Please contact us. Our expert team will

assess your cutting requirements and working conditions to help you find the longer-life solution.

Q: How do you guarantee your quality?

A: All operations from original drawing to final product are strictly controlled and traceable. Never a defective product will be

delivered to our customer.

Q: How long does it take to manufacture a machine knife to customized specification?

A: Normally 35 to 45 days. We can stock special knives for you. Please contact us to discuss your requirements.

Q: What is you payment terms?

A: Payment via Alibaba, TT, L/C are all acceptable.